Giant engineering radial tire mechanical front and back package device

A technology of positive and negative wrapping and radial tires, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of bending deformation and scrapping of the turning rod of the forming drum, not tight wrapping of the cord bead, and difficulty in ensuring the accuracy of pneumatic control. , to achieve the effect of easy internal air discharge, long replacement interval, and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

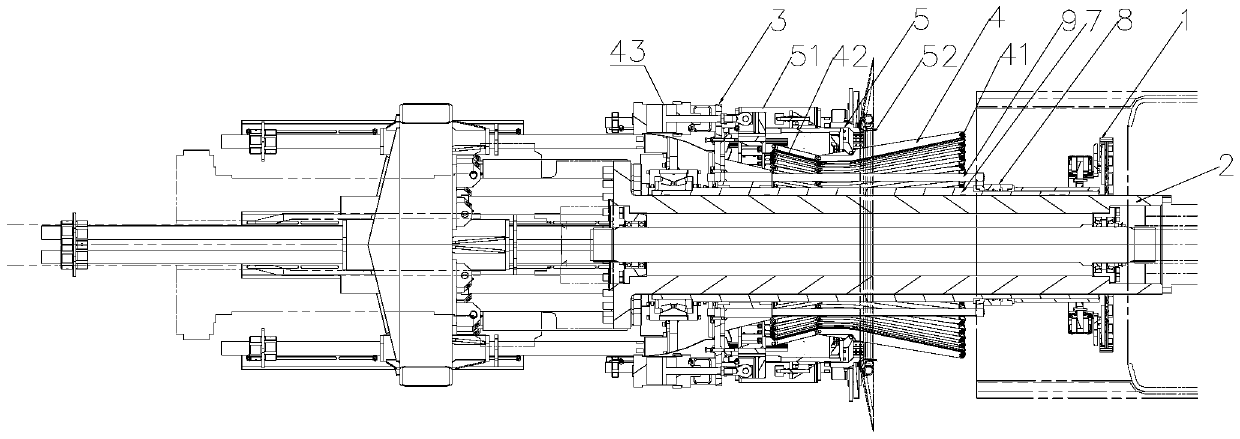

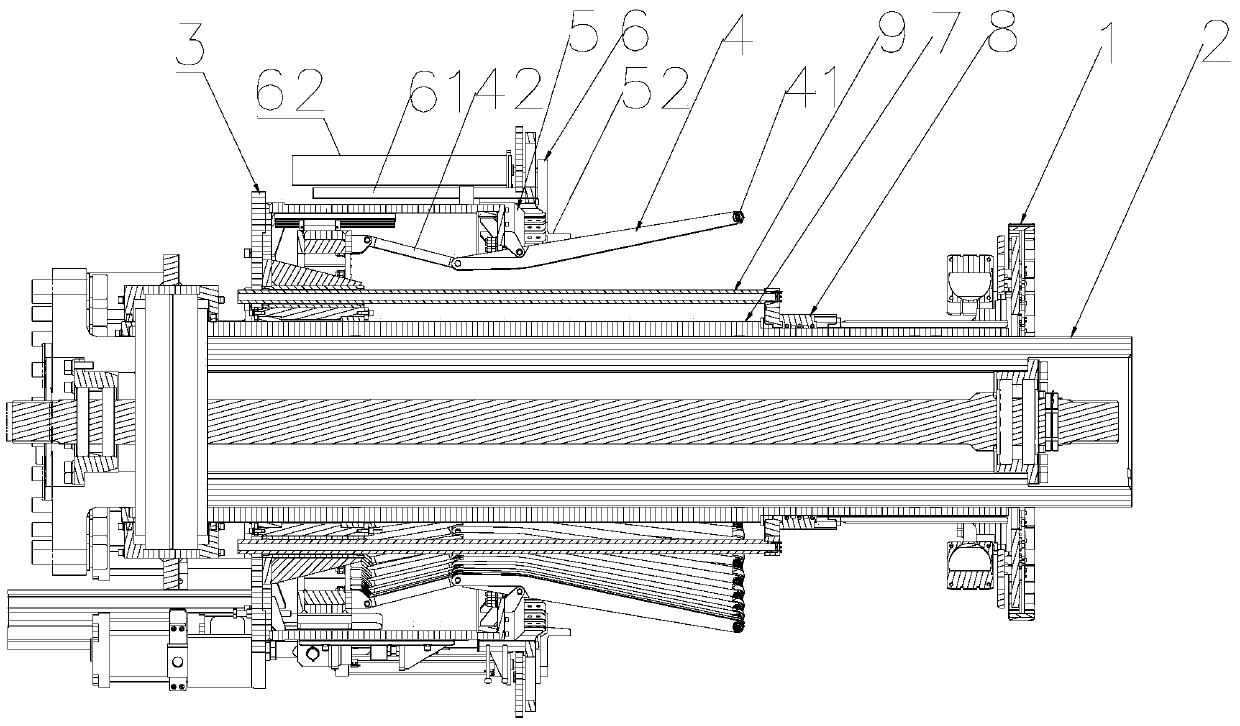

[0014] see Figure 1 to Figure 4 , The giant OTR tire mechanical front and back wrapping device of the present invention includes a front and back wrap push rod opening and closing mechanism and a turn-up device 1 that cooperates with the front and back wrap push rod opening and closing mechanism to turn up the steel ring composite.

[0015] Such as figure 1 and figure 2 As shown, the opening and closing mechanism of the front and back push rods includes a base frame 3 that is installed on the main shaft 2 of the building drum and can move axially. One end of the front-back push rod 4 near the turn-up device 1 is respectively provided with a roller 41, and the other end is respectively driven and connected with a push rod cylinder 43 installed on the base frame 3 through a linkage mechanism 42; There are 48 push rods 4 and they are even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com