Composite ceramic tool with toughness reinforced by graphene nanosheets and microwave preparation technology of composite ceramic tool

A technology of graphene nanosheets and composite ceramics, which is applied in the field of machining tool manufacturing, can solve problems such as low toughness and low production efficiency, achieve low sintering temperature, short heating time, and improve comprehensive mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

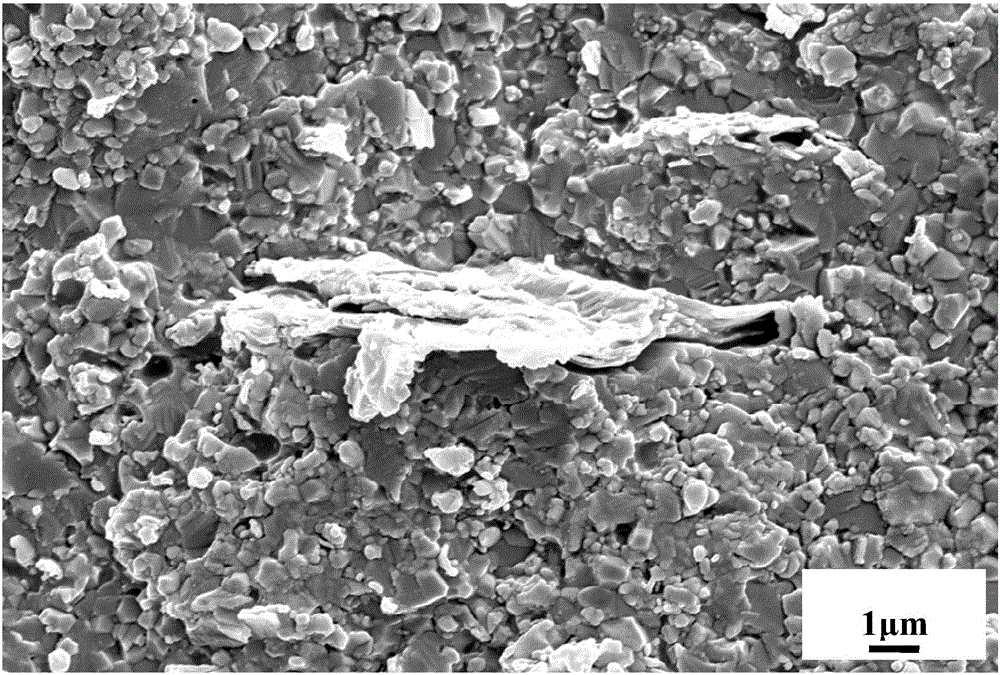

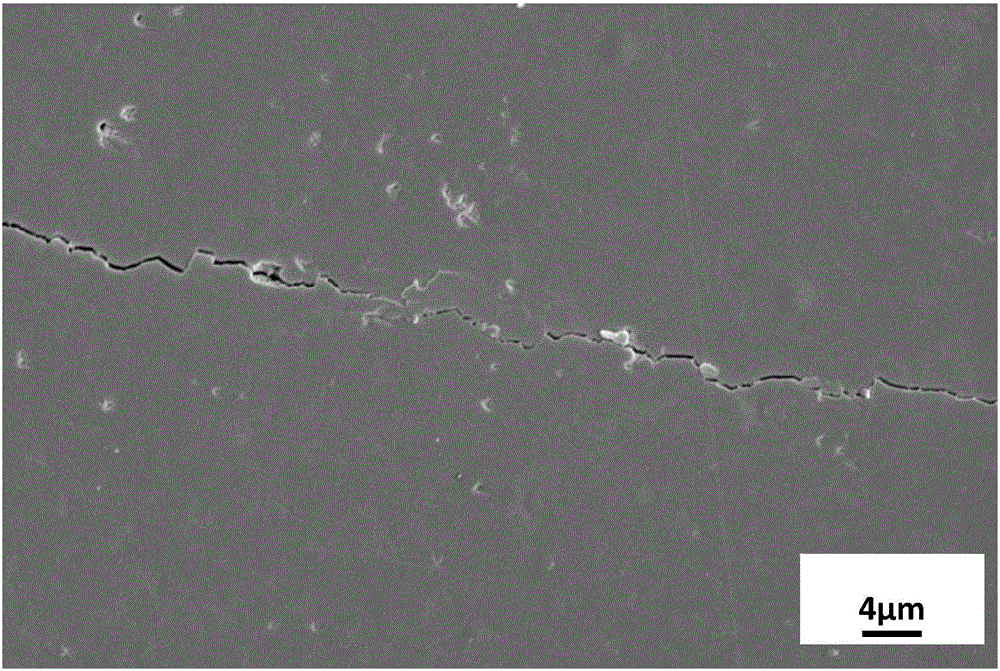

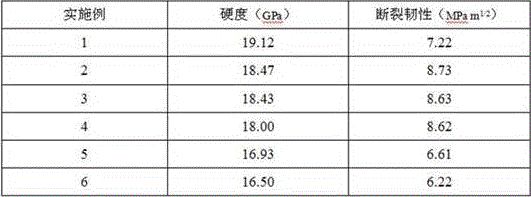

[0025] Weigh graphene nanosheets according to the attached table of the example parameters, and ultrasonically disperse them in 1-methyl-2-pyrrolidone for 2 hours to prepare a suspension; then weigh the submicron Al 2 o 3 , TiC and micron Ni, Mo, Y 2 o 3 and MgO were added to the suspension of graphene nanosheets, ultrasonically dispersed and mechanically stirred for 20 minutes; the mixed solution was added to a planetary ball mill tank, and ball milled for 48 hours; a polyvinyl alcohol solution with a mass concentration of 5wt% was prepared, and after ball milling Add it to the solution for granulation in the first two hours; place the ball-milled mixture in a vacuum oven to dry at 110±10°C, then grind and pass through a 100-mesh sieve to screen the powder; press the screened powder into shape , the molding pressure is 200MPa, and the holding time is 3min, and the sintered green body is obtained. The biscuit is placed in a microwave sintering furnace for microwave sinterin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com