Preparation method and application of poly brominated diphenyl ether polluted water repair material

A polybrominated diphenyl ether and water body restoration technology, which is applied in the fields of water pollutants, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of heavy metal pollution, degradation and poisoning of low-brominated diphenyl ethers, etc., and achieves short restoration time and easy promotion. Ease of use and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

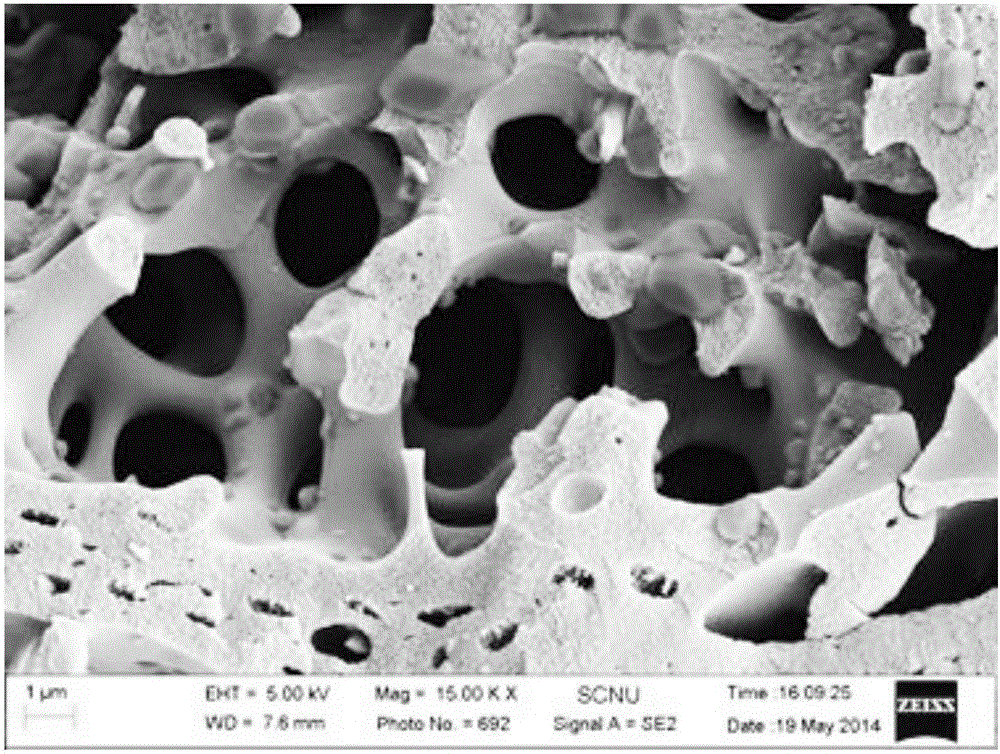

[0055] Embodiment 1: a kind of preparation method of biochar particles, the steps are:

[0056]1) The bagasse is washed, air-dried, and ground by a pulverizer;

[0057] 2) Put the treated sugarcane powder into a crucible, then place it in a muffle furnace, and under the protection of nitrogen, deoxidize and carbonize at a set temperature of 600°C, and continue after reaching the set temperature at a heating rate of 20°C / min Carbonize for 2 hours, and after the temperature of the muffle furnace drops to room temperature, take out the black residue, grind it, pass it through a 60-120 mesh sieve, and seal it for storage.

Embodiment 2

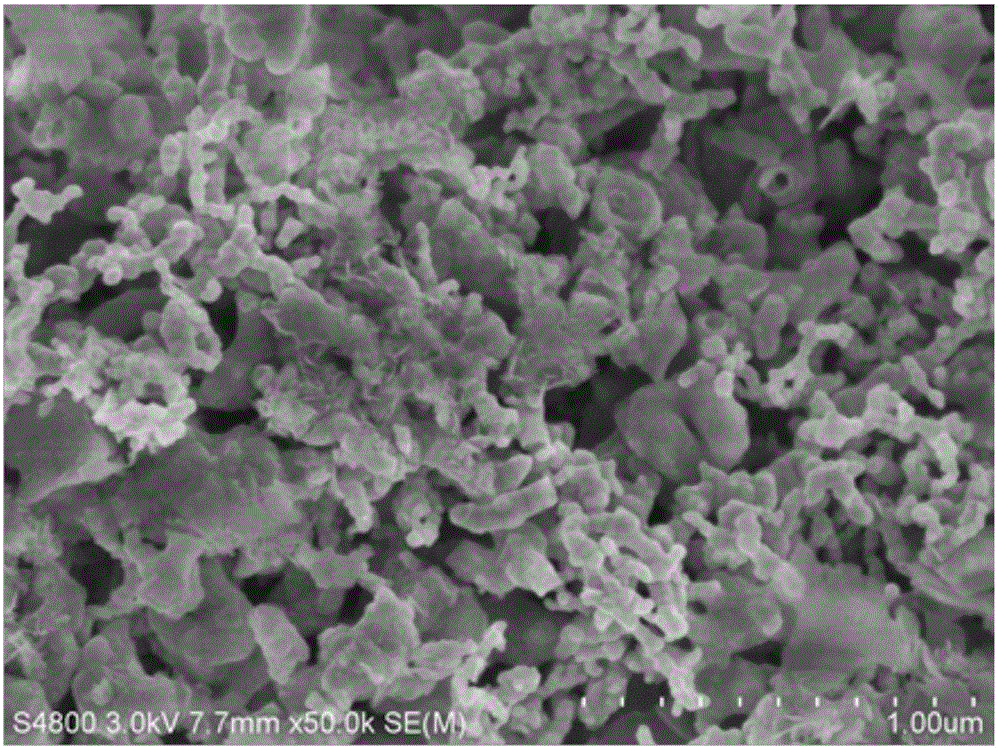

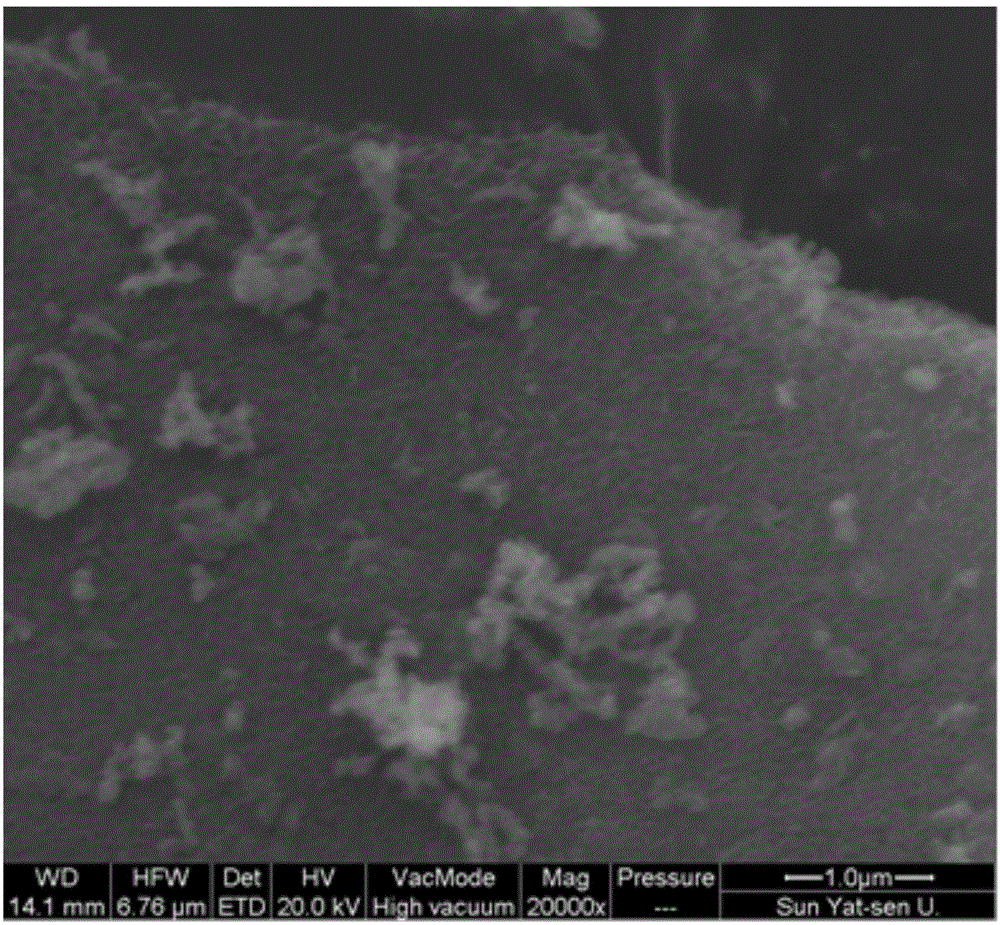

[0059] Embodiment 2: a kind of preparation method of biochar-supported nano-nickel-iron particles, the steps are:

[0060] 1) Prepare 100ml 0.07mol / L FeSO with 30% v / v ethanol solution 4 ·7H 2 The solution of O was stirred at a speed of 300rpm to dissolve and mix evenly, then the biochar particles prepared in Example 2 (the mass ratio of nanometer zero-valent iron to biochar was 1:1) was added therein, and stirred at a speed of 400rpm 1h, make it dissolve and mix to obtain solution A;

[0061] 2) Prepare 50ml of 0.3mol / L sodium borohydride solution with 30% v / v ethanol solution, add it dropwise to solution A under protective atmosphere (nitrogen), and continue to stir the reaction at a speed of 400rpm 30min, and then separated by magnetic separation, after washing, 50ml of 30% v / v ethanol solution was added to obtain solution B.

[0062] 3) Prepare 50ml of 0.2mol / L NiCl with 30% v / v ethanol solution 2 ·6H 2 O solution was quickly added to solution B under stirring conditi...

Embodiment 3

[0064] The preparation method of embodiment 3 nanometer Ni / Fe-biochar composite material

[0065] 1) Prepare 100ml 0.07mol / L FeSO with 30% v / v ethanol solution 4 ·7H 2 The solution of O was stirred at a speed of 300rpm to make it dissolve and mix evenly, then the biochar particles prepared in Example 2 (the mass ratio of nanometer zero-valent iron to biochar was 1:0.5) was added therein, and stirred at a speed of 400rpm 1h, make it dissolve and mix to obtain solution A;

[0066] 2) Prepare 50ml of 0.3mol / L sodium borohydride solution with 30% v / v ethanol solution, add it dropwise to solution A under protective atmosphere (nitrogen), and continue to stir the reaction at a speed of 400rpm 30min, and then separated by magnetic separation, after washing, 50ml of 30% v / v ethanol solution was added to obtain solution B.

[0067] 3) Prepare 50ml of 0.2mol / L NiCl with 30% v / v ethanol solution 2 ·6H 2 O solution, quickly added to solution B under stirring conditions at 400rpm and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com