Carbon-containing slag suppression cold-bonded pellet and utilization method thereof

A technology for cold-solidifying pellets and metallurgical waste, applied in the field of steelmaking, can solve the problem of high cost and achieve the effects of reducing iron consumption, efficient utilization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

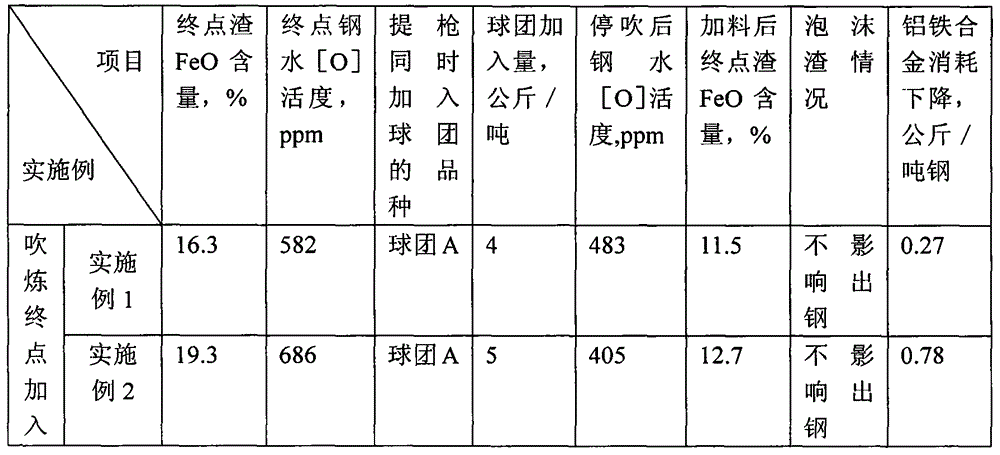

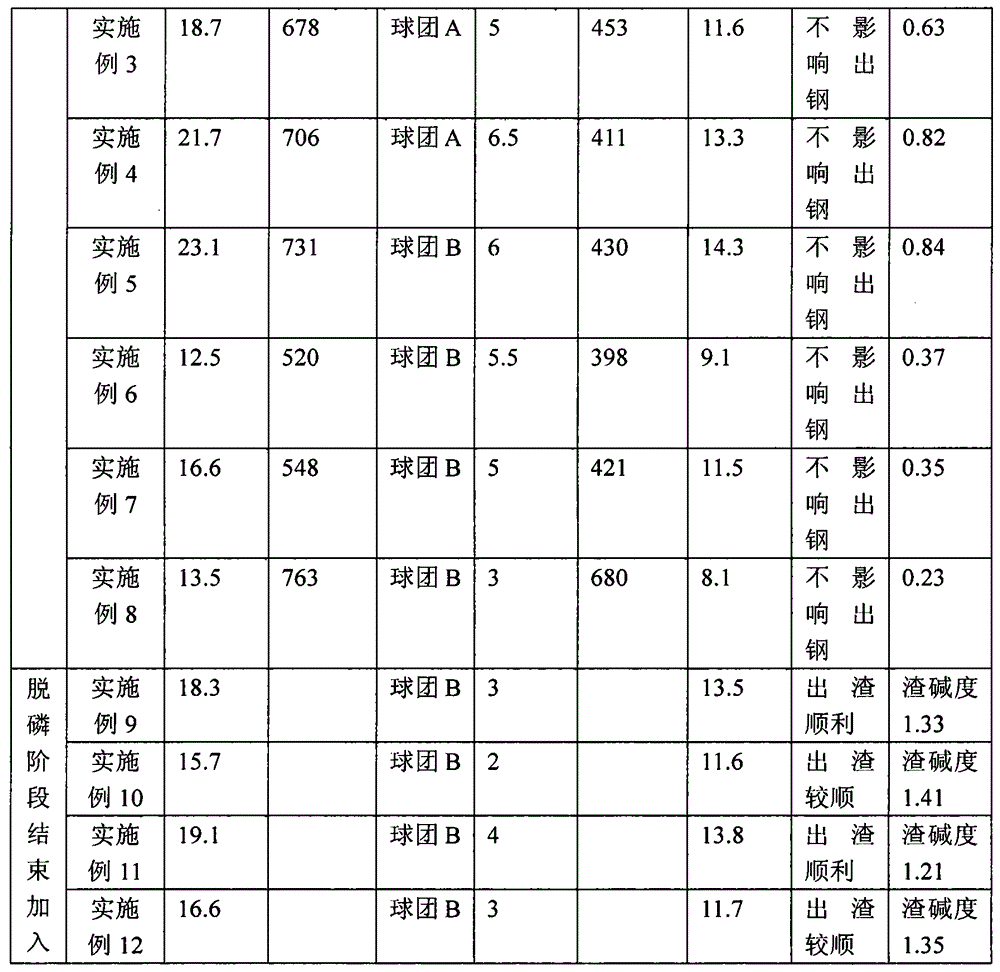

[0005] The embodiment of the present invention selects two technical schemes to make pellets A and pellets B. Into the ball transported to the steel mill. When the converter is about to stop the blowing gun, add 2-10 kg / ton steel into the converter from the high-level silo. The specific addition amount depends on the carbon content of the pellets. Generally, steel with C≤1.5 kg / ton is added into the pellets. Then tap the steel. The specific examples of pellet A and pellet B are as follows:

Embodiment

[0007] Pellet A

[0008] Iron-containing raw materials: rolling oil sludge TFe 50-55%, [gas ash, gas mud] TFe 38%-45, C 30-35%;

[0009] Additives: waste paper pulp, expanded graphite, bentonite.

[0010] Proportion: gas ash: waste paper pulp: steel rolling sludge: bentonite: expanded graphite = 65:15:18:1.5:0.5

[0011] Pelletizing steps: first dry the steel rolling oil sludge and mix it with bentonite in proportion, then put it into the mill for grinding with waste paper pulp, gas ash and expanded graphite in proportion for 30 minutes, mix evenly, the moisture content of the mixture is 9%, and after cooling The compression molding machine is pressed into balls under a pressure of 200 tons, and then left for 48 hours, the dry ball compressive strength is 2680N. The processed cold-solidified pellets contain 38.2% of TFe, 21.5% of C, 11.5% of volatile matter, and the balance is CaO and SiO 2 、Al 2 o 3 , MgO, ZnO, K 2 O, Na 2 O etc., specific gravity 2.59 g / cm 3 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com