Solar cell boron diffusion method and boron diffusion device

A technology of solar cells and diffusion methods, which is applied in the field of solar cell boron diffusion methods and boron diffusion devices, can solve problems such as uneven deposition, corrosion diffusion furnace doors, and cracking of quartz devices, so as to improve inter-chip uniformity and improve intra-chip Uniformity, to achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

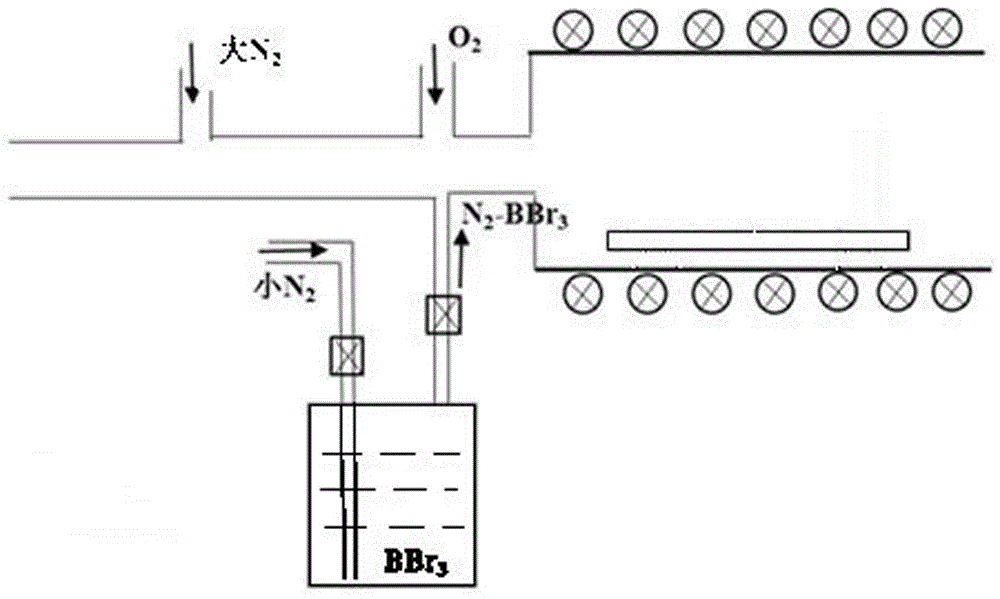

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0039] The idea of the present invention is to introduce low-boiling boride substances in the diffusion process and distribute them in gaseous form at the diffusion temperature, so as to promote the uniform deposition of boron on the surface of the silicon wafer and improve the doping uniformity of the diffusion layer. Boron oxide is easy to absorb moisture and forms boric acid or metaboric acid. These two substances are easily decomposed into boron oxide under high temperature, and boric acid or metaboric acid has a low boiling point and is gaseous at the diffusion temperature. That is to say, boron oxide, boric acid, and metaboric acid can achieve mutual conversion, so we can introduce a certain amount of water during the diffusion process to form boric acid or metaboric acid with a low boiling point.

[0040] The present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com