Long-acting anti-corrosion method for lined type prestressed concrete cylinder pipe

A technology of prestressed steel and concrete pipes, applied in the direction of anti-corrosion/anti-rust protection of pipelines, pipes, rigid pipes, etc. Hardened mortar cracks and other problems, to achieve the effect of improving production efficiency, long-term corrosion protection, and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

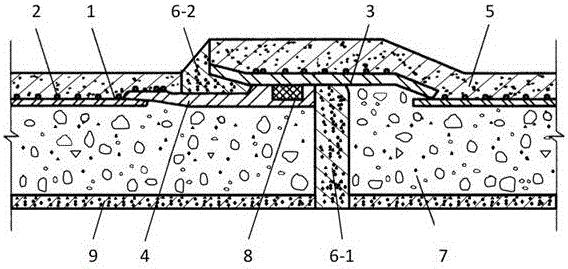

[0041] Lined prestressed steel cylinder concrete pipe (PCCPL) steel cylinder, prestressed steel wire, part of the socket steel ring and part of the socket steel ring of the factory-made ultra-high performance concrete outer cover 5 and the factory-made ultra-high performance concrete inner cover 9, Finished in the factory. After the pipeline is installed in place, the on-site ultra-high-performance concrete inner protective layer 6-1 and the on-site ultra-high-performance concrete outer protective layer 6-2 of the exposed parts of the socket steel ring and the socket steel ring are fabricated on the pipeline installation site Finish. Specific steps are as follows:

[0042] 1. Prepare cohesive ultra-high performance concrete in the factory: the slump of the freshly mixed mixture is 30~100mm, which is suitable for mechanical roller injection, spraying or troweling to make a protective layer. The hardening performance of ultra-high performance concrete (standard curing 28 days)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com