Reference pixel for uncooled infrared detector and manufacturing method of reference pixel

A technology of uncooled infrared and manufacturing methods, which is applied in the fields of electric radiation detectors, final product manufacturing, radiation pyrometry, etc., and can solve the problems of reducing product yield, increasing process steps and manufacturing difficulty, increasing manufacturing cycle and manufacturing cost, etc. problems, to shorten the manufacturing cycle, eliminate thermal radiation interference factors, and improve device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

[0034] The present invention provides a method for manufacturing a reference pixel of an uncooled infrared detector. The specific process steps are as follows:

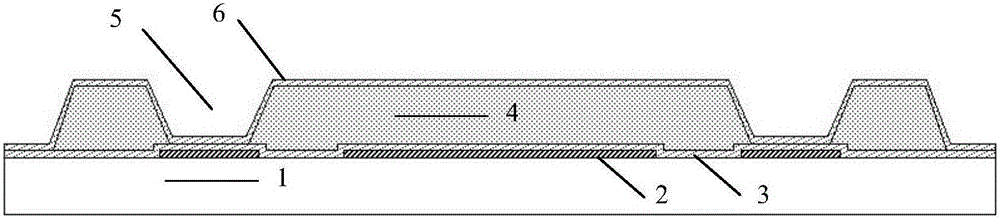

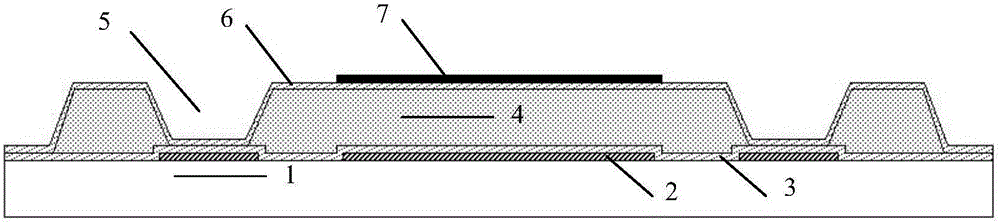

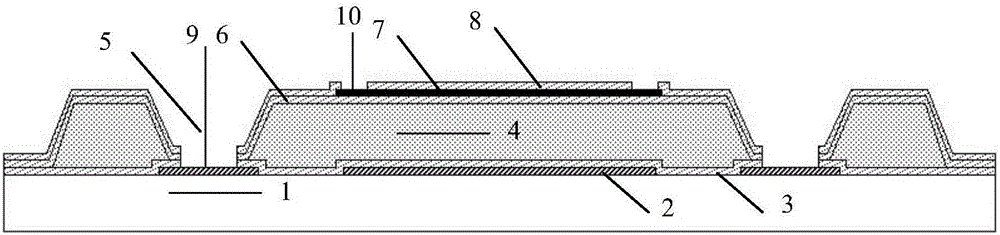

[0035] Such as Figure 1-5 Shown:

[0036] Step 1. Deposit a metal reflective layer 2, an insulating dielectric layer 3, and a spin-coated sacrificial layer 4 on the ASIC circuit (application-specific integrated circuit) 1 in sequence, and etch the bridge pier holes through the sacrificial layer 4 on the sacrificial layer 4 5;

[0037] Step 2. Depositing a support layer 6, a thermosensitive film 7 and a dielectric protective layer 8 on the sacrificial layer 4 in sequence;

[0038] Step 3. Prepare a through hole 9 in the bridge pier hole 5, the through hole 9 is located o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com