A kind of preparation method of 5-aminosalicylic acid

A technology of aminosalicylic acid and nitrosalicylic acid, which is applied in the preparation of nitro compounds, organic compounds, cyanide reaction, etc., can solve the problem of severe exothermic heat of nitration reaction, a large amount of waste acid and iron powder, and safety Production hidden dangers and other problems, to achieve the effect of controllable heat release, improved utilization rate, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Weigh 80g of salicylic acid dissolved in 800ml of acetic acid as material 1, the molar concentration of salicylic acid in material 1 is 0.72mol / L; weigh 120g of concentrated nitric acid dissolved in 300ml of acetic acid as material 2, The molar concentration of nitric acid in material 2 is 3.2mol / L; 100ml of concentrated sulfuric acid is measured as material 3. The concentrated sulfuric acid is conventional commercial concentrated sulfuric acid, and the molar concentration is 18mol / L;

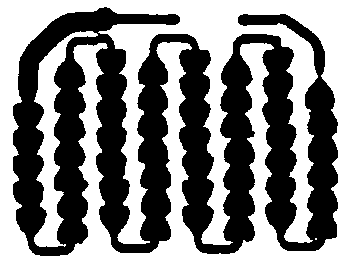

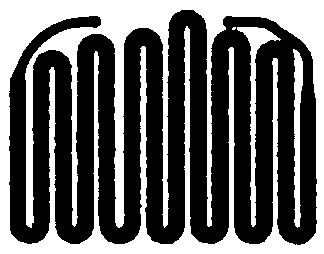

[0043] The flow rate of control material 1 is 22ml / min; the flow rate of control material 2 is 12ml / min; the flow rate of control material 3 is 6ml / min, and the material 1 is preheated to the reaction temperature in the first preheating module 11, and the material 2 and material 3 are in the second The preheating module 12 is mixed and preheated to the reaction temperature; then the material 1, the material 2 and the material 3 flow into the first reaction module 13, and the first reacti...

Embodiment 2

[0048] (1) Weigh 100 g of salicylic acid dissolved in 1000 ml of acetic acid as material 1, and the molar concentration of salicylic acid in material 1 is 0.72 mol / L; weigh 150 g of concentrated nitric acid and dissolve in 375 ml of acetic acid as material 2, The molar concentration of nitric acid in material 2 is 3.2 mol / L; 120ml of concentrated sulfuric acid is measured as material 3. The concentrated sulfuric acid is conventional commercial concentrated sulfuric acid, and the molar concentration is 18 mol / L;

[0049] Control the flow rate of material 1 to 20ml / min; control the flow rate of material 2 to 10ml / min; control the flow rate of material 3 to 5ml / min, the material 1 is preheated to the reaction temperature in the first preheating module 11, and the material 2 and material 3 are in the second The preheating module 12 is mixed and preheated to the reaction temperature; then the material 1, the material 2 and the material 3 flow into the first reaction module 13, where th...

Embodiment 3

[0054] (1) Weigh 90g of salicylic acid dissolved in 900ml of acetic acid as material 1. The molar concentration of salicylic acid in material 1 is 0.72mol / L; weigh 150g of concentrated nitric acid and dissolve in 375ml of acetic acid as material 2. The molar concentration of nitric acid in material 2 is 3.2 mol / L; 120ml of concentrated sulfuric acid is measured as material 3. The concentrated sulfuric acid is conventional commercial concentrated sulfuric acid, and the molar concentration is 18 mol / L;

[0055] Control the flow rate of material 1 to 25ml / min; control the flow rate of material 2 to 12ml / min; control the flow rate of material 3 to 6ml / min, material 1 is preheated to the reaction temperature in the first pre-heat preservation module 11, and material 2 and material 3 are in the second The preheating module 12 is mixed and preheated to the reaction temperature; then the material 1, the material 2 and the material 3 flow into the first reaction module 13, where they are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com