Computer data connecting wire

A data connection line and computer technology, applied in the direction of cable/conductor manufacturing, conductors, electrical components, etc., can solve the problems of poor deformation resistance, achieve superior flame retardancy, soft texture, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

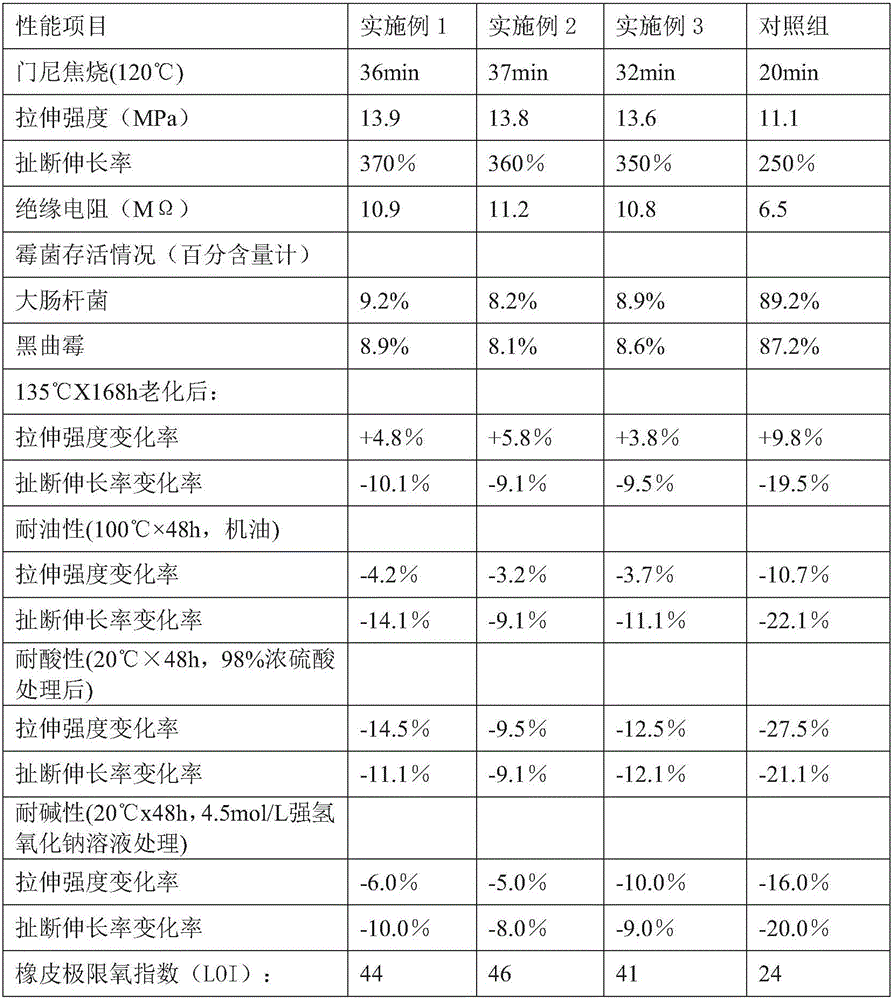

Examples

Embodiment 1

[0017] The computer data connection line in this embodiment includes a plurality of copper alloy wires and protective sleeves. The copper alloy wires are placed parallel to each other. The outer layer of each copper alloy wire is covered with a protective sleeve. The protective sleeve is composed of the following parts by mass Component composition: 28 parts of bisphenol A polycarbonate, 26 parts of rosin calcium soap, 26 parts of vinyl resin, 24 parts of coal tar, 26 parts of tallow dihydroxyethylamine oxide, 26 parts of hydrogenated soybean oil, pine oil 24 parts of alcohol, 26 parts of tung oil, 26 parts of mugwort leaf extract, 24 parts of garlic extract, 24 parts of isothiazolinone, 24 parts of imperata, 26 parts of ash calcium powder, 24 parts of volcanic ash, 22 parts of methallyl sulfide Parts, 26 parts of coke gem powder, 24 parts of coke, 22 parts of sodium polymethacrylate, 24 parts of sericite powder, 22 parts of Tripterygium wilfordii, 22 parts of ammonium polyphos...

Embodiment 2

[0024]The computer data connection line in this embodiment includes a plurality of copper alloy wires and protective sleeves. The copper alloy wires are placed parallel to each other. The outer layer of each copper alloy wire is covered with a protective sleeve. The protective sleeve is composed of the following parts by mass Component composition: 30 parts of bisphenol A polycarbonate, 28 parts of rosin calcium soap, 28 parts of vinyl resin, 26 parts of coal tar, 28 parts of tallow dihydroxyethylamine oxide, 28 parts of hydrogenated soybean oil, pine oil 26 parts of alcohol, 28 parts of tung oil, 28 parts of mugwort leaf extract, 26 parts of garlic extract, 26 parts of isothiazolinone, 26 parts of imperata, 28 parts of ash calcium powder, 26 parts of volcanic ash, 24 parts of methallyl sulfide Parts, 28 parts of coke gem powder, 26 parts of coke, 24 parts of sodium polymethacrylate, 26 parts of sericite powder, 24 parts of Tripterygium wilfordii, 24 parts of ammonium polyphosp...

Embodiment 3

[0031] The computer data connection line in this embodiment includes a plurality of copper alloy wires and protective sleeves. The copper alloy wires are placed parallel to each other. The outer layer of each copper alloy wire is covered with a protective sleeve. The protective sleeve is composed of the following parts by mass Component composition: 32 parts of bisphenol A polycarbonate, 30 parts of rosin calcium soap, 30 parts of vinyl resin, 28 parts of coal tar, 30 parts of tallow dihydroxyethylamine oxide, 30 parts of hydrogenated soybean oil, pine oil 28 parts of alcohol, 30 parts of tung oil, 30 parts of mugwort leaf extract, 28 parts of garlic extract, 28 parts of isothiazolinone, 28 parts of imperata, 30 parts of ash calcium powder, 28 parts of volcanic ash, 26 parts of methallyl sulfide Parts, 30 parts of coke gem powder, 28 parts of coke, 26 parts of sodium polymethacrylate, 28 parts of sericite powder, 26 parts of Tripterygium wilfordii, 26 parts of ammonium polyphos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com