Anti-reflecting heterojunction composite coating and preparation method thereof

A composite coating and heterojunction technology, which is applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., can solve the problems of unfavorable multi-functionalization of biomimetic cone materials and limit the scope of application, so as to improve the optoelectronic Conversion efficiency, high-efficiency photoelectric conversion efficiency, and the effect of broadening the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

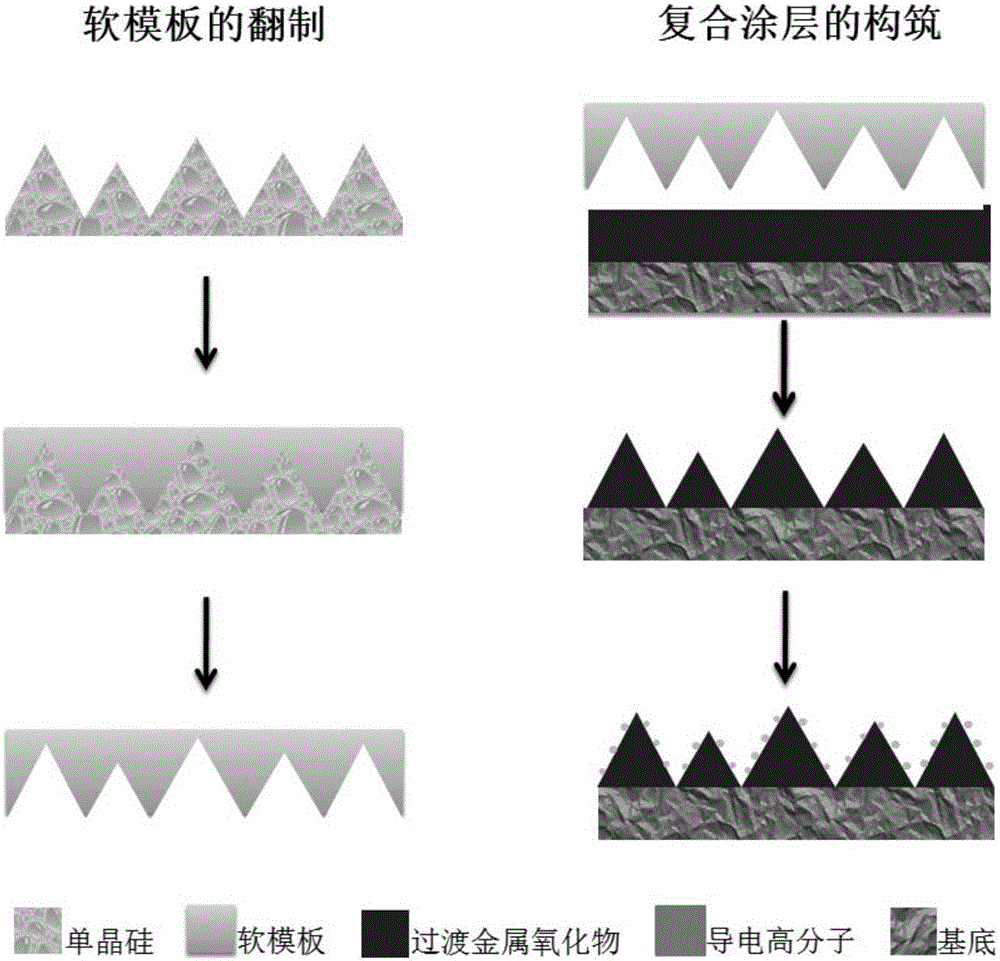

[0035] 1) Preparation of micron-sized silicon cones:

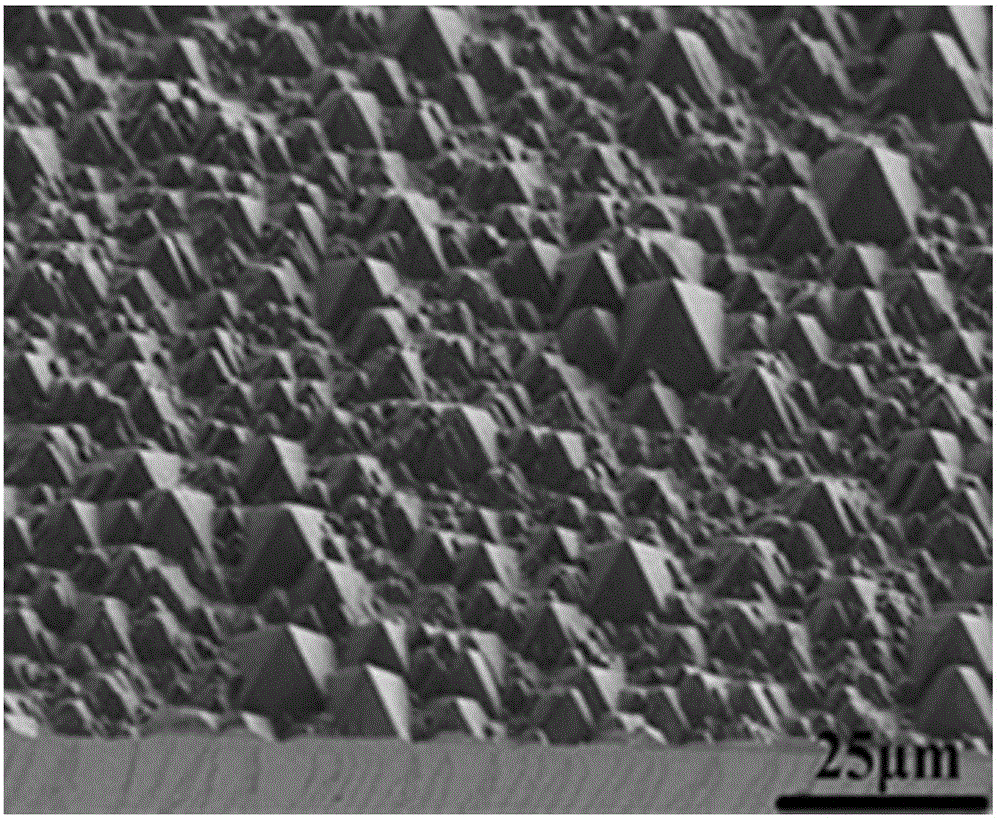

[0036] Cut the 100-type single crystal silicon wafer into 1.5cm×1.0cm, and ultrasonically clean it in acetone, chloroform, ethanol and water for 5 minutes to remove the contamination on the surface of the silicon wafer; then place the cleaned silicon wafer in a concentration of 1mol / L hydrogen In the isopropanol solution of potassium oxide, under the condition of mechanical stirring, etch in a water bath at 50°C for 30min, to obtain silicon cones with an average height of 3μm, such as figure 2 shown.

[0037] 2) Preparation of PDMS soft template:

[0038] Mix the PDMS prepolymer and the curing agent at a mass ratio of 10:1, pour it on the silicon cone structure, put it in an oven at 75 ° C for 2 hours, and peel it off from the rigid template after cooling to obtain a silicon cone template structure. Complementary PDMS soft template.

[0039] 3) TiO 2 Sol preparation:

[0040]First, mix 5mL of n-tetrabutyl titanate wi...

Embodiment 2

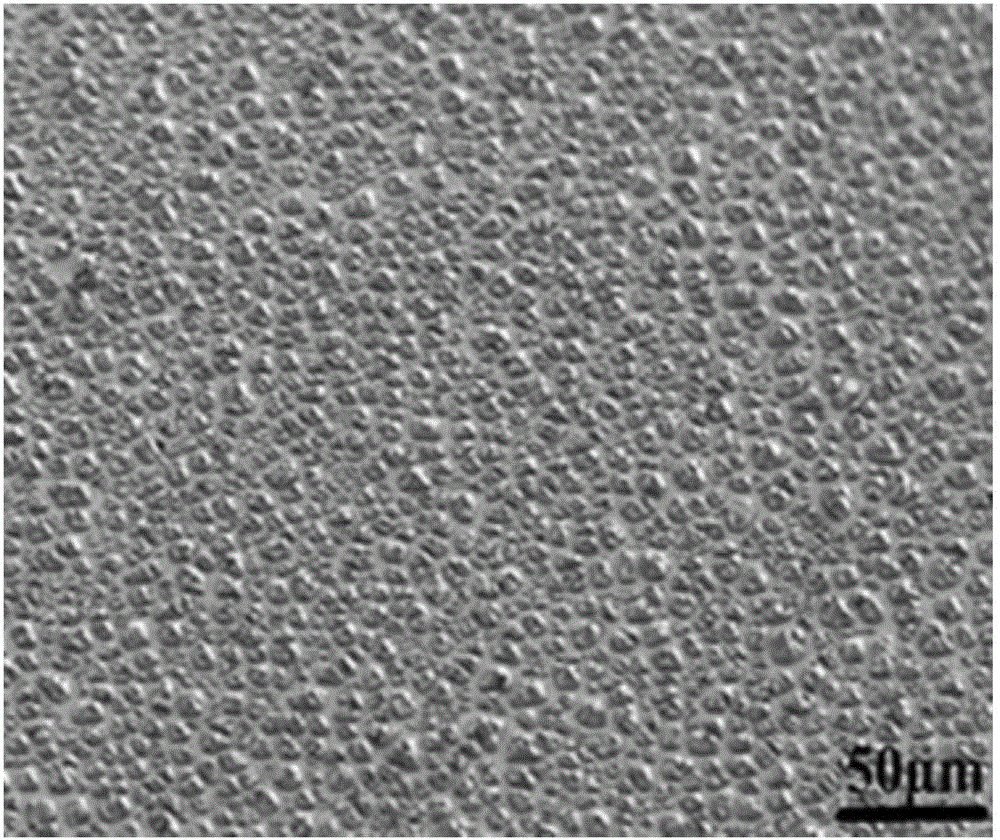

[0046] Surface reflectance of anti-reflection heterojunction composite coating:

[0047] Gained PANI / TiO in embodiment 1 2 / Si for anti-reflection performance testing, using an integrating sphere to collect its reflection spectra in ultraviolet, visible, and near-infrared, the results are shown in Figure 5 , in which conical TiO without PANI nanoparticles on the surface 2 (TiO 2 / Si) and planar TiO 2 As a comparative sample (F-TiO 2 / Si). PANI / TiO 2 Micrometer-sized cones and nanometer-sized particles in Si / Si can achieve good anti-reflection in both long-wave and short-wave ranges, and the reflectivity can reach as low as 3%, which is much lower than that of TiO 2 / Si and F-TiO 2 / Si sample reflectance.

Embodiment 3

[0049] Photoelectric properties of anti-reflection heterojunction composite coatings:

[0050] Gained PANI / TiO in embodiment 1 2 / Si for photocurrent detection, see the results Figure 6 , in which the conical TiO without polyaniline nanoparticles on the surface 2 (TiO 2 / Si) as a comparative sample. During the test, the sample to be tested is used as the working electrode, the conductive glass coated with platinum is used as the counter electrode, Ag / AgCl is used as the reference electrode, and 0.3mol / L Na 2 SO 4 As the electrolyte, the xenon lamp is a simulated sunlight light source. In the absence of light, the electrons in the semiconductor are confined in the valence band, so there is no directional movement of electrons in the circuit, and no current is generated. When light is applied to the working electrode, electrons are excited to jump from the valence band to the conduction band, and a current is generated in the circuit. Under the same light conditions, wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com