Corrosion-resistant high-reflection front mirror and preparation method thereof

A high-reflective, corrosion-resistant technology, applied in optics, mirrors, optical components, etc., can solve the problems of easy damage, weak scratch resistance of the dielectric layer, weakened absorption of reflected energy and light, and achieve simple preparation process and overcome The preparation process is complicated, the technology is insufficient, and the effect of high reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

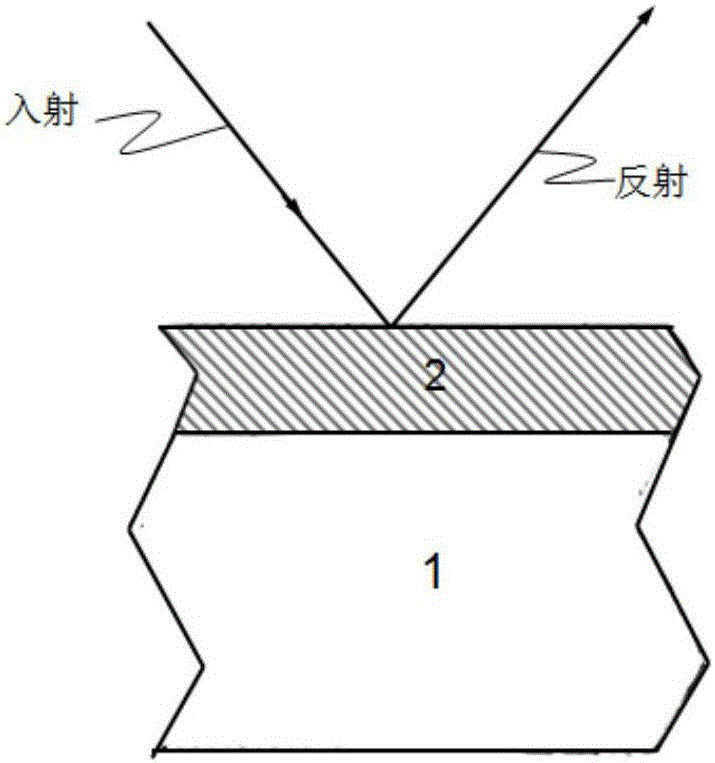

[0039] Front mirror of the present invention adopts physical vapor phase magnetron sputtering deposition, as figure 1 As shown, first put the flat plate-shaped glass substrate 1 into acetone, absolute ethanol, and deionized water for 15 minutes, and then blast it in a drying oven at a temperature of 100 ° C for 2 hours; then fix it in a vacuum chamber On the rotatable sample stage, the plasma generated by argon gas was used to etch it for 10 min. When the chamber vacuum is less than 2×10 -5 Pa, rush into Ar gas and adjust the sputtering pressure to 0.5Pa, select the composition as (Ti 75 Al 25 ) 50 B 50 The target is connected to the pulse power supply, and the power density of the target is adjusted to 8.5W / cm 2 , and the substrate was grounded and heated at 100°C, then the baffle was opened, and the surface of the glass substrate 1 was deposited to obtain the composition (Ti 75 Al 25 ) 50 B 50 Reflective coating2.

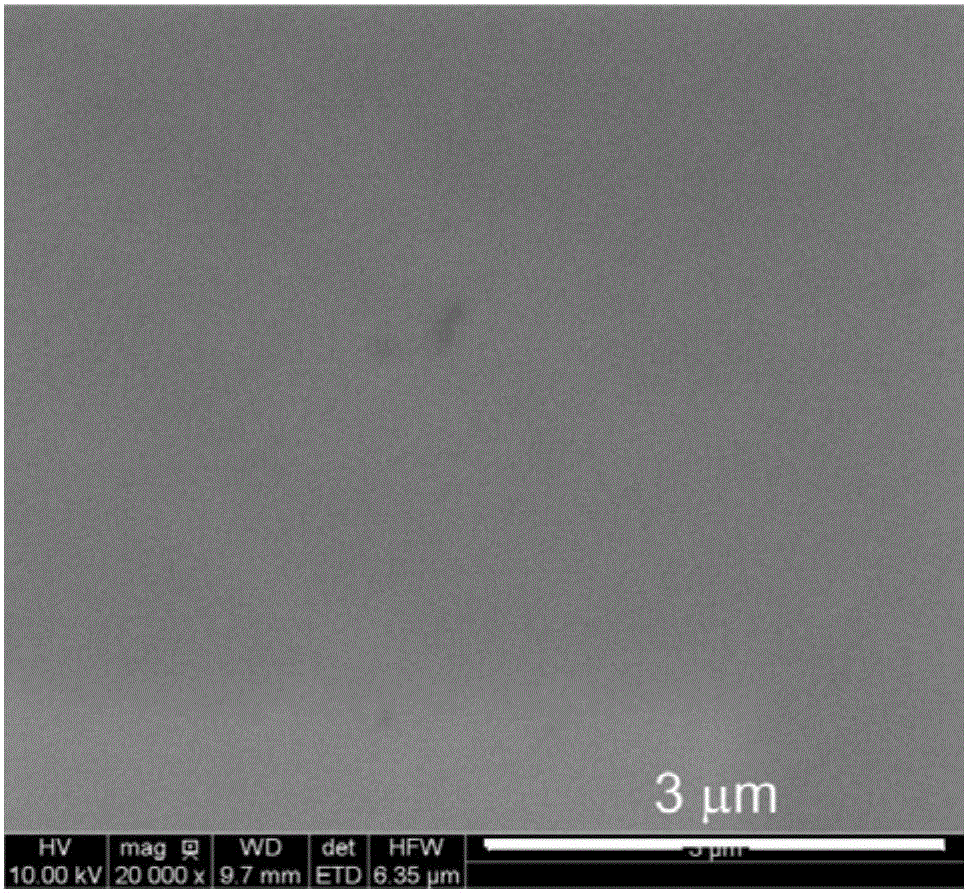

[0040] The reflective coating has an amorphous st...

Embodiment 2

[0042] Front mirror of the present invention adopts physical vapor phase magnetron sputtering deposition, as figure 1 As shown, first put the flat plate-shaped glass substrate 1 into acetone, absolute ethanol, and deionized water for 20 minutes, and then blast it in a drying oven at a temperature of 80 ° C for 2 hours; then fix it in a vacuum chamber On the rotatable sample stage, the plasma generated by argon gas was used to etch it for 20 min. When the chamber vacuum is less than 1×10 -5 Pa, rush into Ar gas and adjust the sputtering pressure to 0.7Pa, select the composition as (Ti 92 Mo 8 ) 70 B 30 The target is connected to the pulse power supply, and the power density of the target is adjusted to 20W / cm 2 , and the substrate was subjected to -20V DC bias and heated at 300°C, then the baffle was opened, and the surface of the glass substrate 1 was deposited to obtain a composition of (Ti 92 Mo 8 ) 70 B 30 Reflective coating2.

[0043] Detected by X-ray diffractom...

Embodiment 3

[0045] Front mirror of the present invention adopts physical vapor phase magnetron sputtering deposition, as figure 1 As shown, firstly, put the flat glass substrate 1 into acetone, absolute ethanol, and deionized water for 10 minutes, and then use high-purity N with a purity of 99.99%. 2 Blow dry; then fix it on a rotatable sample stage in a vacuum chamber, and etch it for 15 min with plasma generated by argon gas. When the chamber vacuum is less than 3.6×10 -5 Pa, rush into Ar gas and adjust the sputtering pressure to 0.5Pa, select the composition as Ti 50 B 50 The target is connected to the pulse power supply, and the power density of the target is adjusted to 13W / cm 2 , and the substrate was treated with pulsed negative bias of -30V and heated at 200°C, then the baffle was opened, and the surface of the glass substrate 1 was deposited to obtain a composition of Ti 50 B 50 reflective coating2.

[0046] Detected by X-ray diffractometer (XRD), the coating has an amorpho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com