Enamel glaze material, enamel slurry, and preparation method and application thereof

A technology for enamel glaze and slurry, applied in the field of enamel glaze, can solve the problems of poor glaze gloss, low acid resistance, pores, etc. , combined with a strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

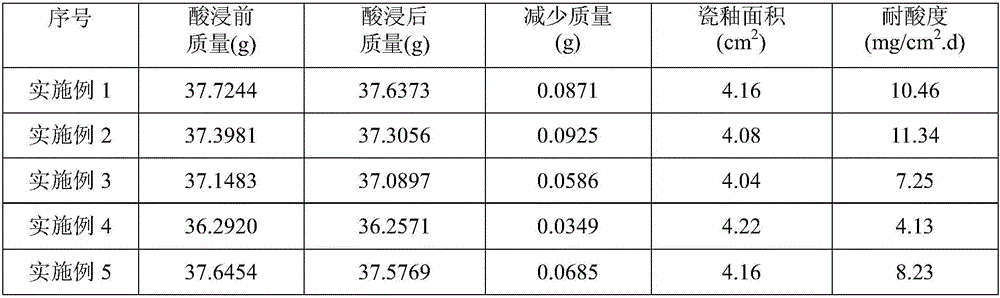

Examples

preparation example Construction

[0034] The preparation method of the above-mentioned enamel slurry includes the following steps: adding 100 parts of enamel glaze, 30-50 parts of glass powder, 0.3-0.5 parts of borax, 0.2-0.5 parts of sodium nitrite, 5-7 parts of clay, and 0.5-1 part of bentonite. 1 part, 0.5-1 part of sodium fluorosilicate, and 35-40 parts of water to obtain a mixture, which is then added to ball and ball mill to obtain enamel slurry.

[0035] Preferably, in the above-mentioned preparation method of enamel slurry, the zirconia balls are a mixture of two kinds of balls with diameters of 5 mm and 2 mm. The two sizes of balls are mixed for easy ball milling. The mass ratio of the zirconia balls to the mixture is 1-1.2:1. If the ratio of the total mass of the ball to the total mass of the mixture is large, each time the material is less abrasive and the ratio is small, the grinding time will be longer.

[0036] Preferably, in the above-mentioned preparation method of enamel slurry, the rotation...

Embodiment 1

[0046] Preparation of enamel glaze: weigh 40 parts of quartz sand, 9.5 parts of feldspar powder, 24 parts of borax, 2.5 parts of cryolite, 5.5 parts of sodium nitrate, 3.5 parts of lithium carbonate, 3.5 parts of fluorite powder, 2.5 parts of calcium carbonate, 3 parts of cobalt nitrate, 0.8 parts of nickel nitrate, 2 parts of manganese oxide, and 3.4 parts of zirconium dioxide are mixed evenly, and pulverized in a ball mill to a particle size of 80 mesh; the mixture is transferred to an electric furnace or kiln and heated to 850 ℃ for 60 minutes, and then Heating to 1300°C for 100min to obtain uniform molten enamel, then immediately pouring the molten enamel into cold water to quench and smash, and drying at 130°C for 30min to obtain enamel glaze.

[0047] Preparation of glass powder: The waste glass is rolled into 5mm flakes, washed, dried, pulverized by a ball mill, and passed through a 140-mesh sieve to obtain glass powder.

[0048] Preparation of enamel slurry: by weight,...

Embodiment 2

[0052] Preparation of enamel glaze: weigh 40 parts of quartz sand, 9.5 parts of feldspar powder, 24 parts of borax, 2.5 parts of cryolite, 5.5 parts of sodium nitrate, 4 parts of lithium carbonate, 3.5 parts of fluorite powder, 2.5 parts of calcium carbonate, 3 parts of cobalt nitrate, 0.8 parts of nickel nitrate, 2 parts of manganese oxide, and 3.4 parts of zirconium dioxide are mixed evenly, and pulverized in a ball mill to a particle size of 80 mesh. Transfer the mixture into an electric furnace or a kiln and heat it to 850°C for 40 minutes, then heat it to 1300°C for 90 minutes to obtain a uniform molten enamel, then immediately pour the molten enamel into cold water to quench it, and dry it at 130°C 30min to get enamel glaze.

[0053] Preparation of glass powder: The waste glass is rolled into 5mm flakes, washed, dried, pulverized by a ball mill, and passed through a 140-mesh sieve to obtain glass powder.

[0054] Preparation of enamel slurry: by weight, mix 100 parts of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| acid resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com