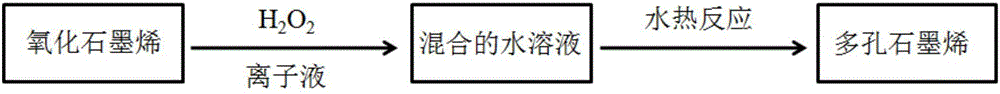

Preparation method of porous graphene

A porous graphene and graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as difficult precise preparation of graphene and restrictions on graphene application, and achieve excellent electrochemical performance and mild conditions , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Graphene oxide used in the present embodiment is to be raw material with flake graphite, is prepared by traditional hummers method; Ionic liquid is 1-butyl-3-methylimidazole L lactate, prepares porous graphene:

[0024] Step 1: Weigh 400 mg of freeze-dried graphene oxide GO powder, dissolve it in 40 mL of distilled water, disperse it ultrasonically for 1 h to form a graphene oxide aqueous solution, add 1 mL of hydrogen peroxide solution with a mass concentration of 30% drop by drop, and stir well 2h;

[0025] Step 2: Add 200 mg of 1-butyl-3-methylimidazole L-lactate ionic liquid dropwise to the dispersion obtained in step 1, and stir thoroughly for 2 hours;

[0026] Step 3: transfer the mixed solution obtained in step 2 to a 50mL hydrothermal reaction kettle, and react at 140°C for 12 hours;

[0027] Step 4: Freeze-drying the gel obtained by the hydrothermal reaction in Step 3 to obtain the porous graphene.

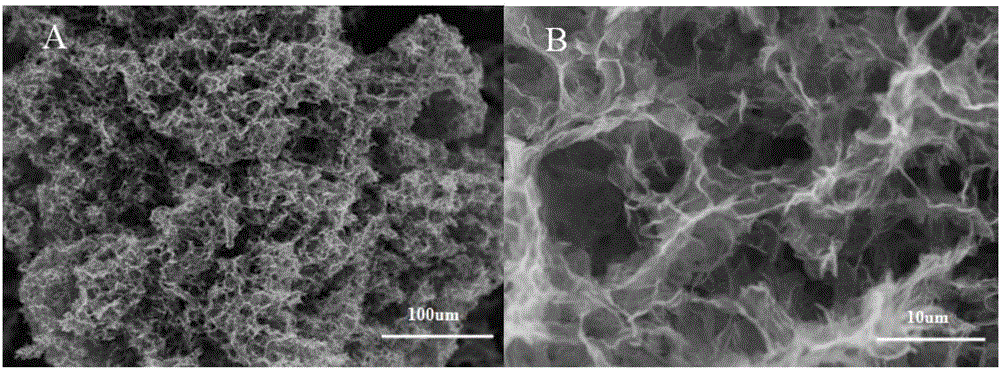

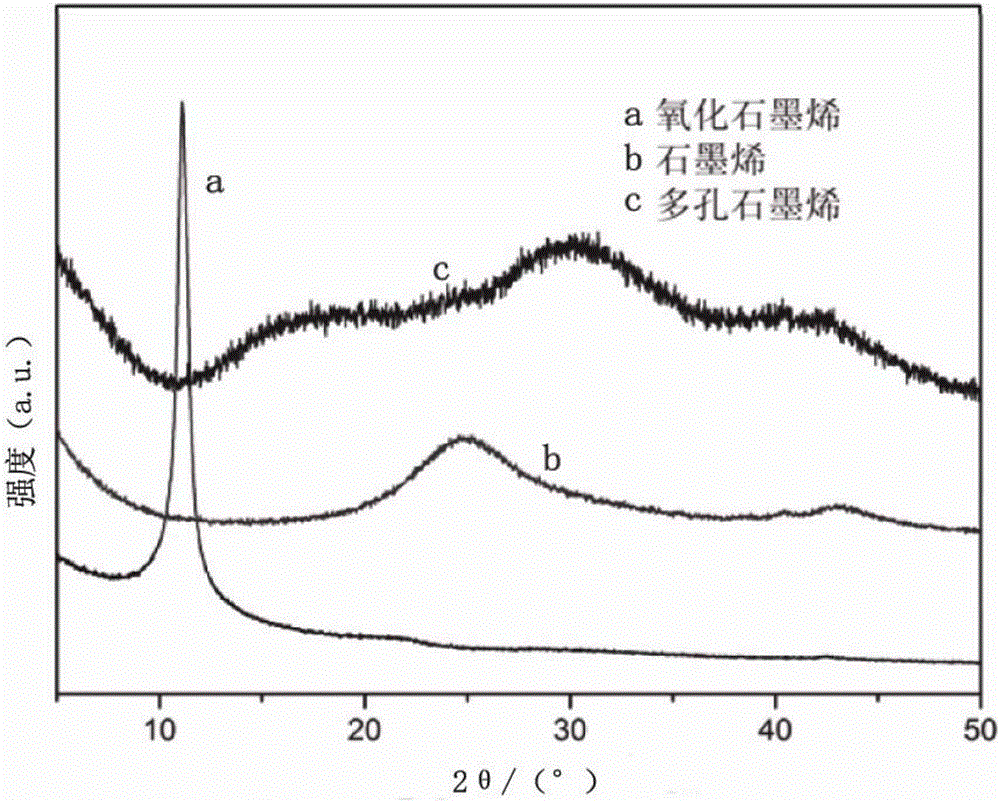

[0028] The obtained porous graphene is characterized, and t...

Embodiment 2

[0030] Graphene oxide used in the present embodiment is to be raw material with flake graphite, is prepared by traditional hummers method; Used ionic liquid is 1,2-ethylenediamine nitrate, prepares porous graphene material:

[0031] Step 1: Weigh 400mg of lyophilized GO powder, dissolve it in 40mL of distilled water, disperse it by ultrasonic for 1h, make it fully dispersed to form a graphene oxide aqueous solution, and add 1mL of hydrogen peroxide solution with a mass concentration of 30% drop by drop; and Fully stir for 2h;

[0032] Step 2: Add 200 mg of 1,2-ethylenediamine nitrate ionic liquid dropwise to the dispersion obtained in step 1, and stir thoroughly for 2 hours;

[0033] Step 3: Transfer the mixed solution obtained in the above steps to a 50mL hydrothermal reaction kettle, and react at 140°C for 14 hours;

[0034] Step 4: Freeze-drying the gel obtained by the hydrothermal reaction in Step 3 to obtain the porous graphene.

Embodiment 3

[0036] The graphene oxide used in the present embodiment is to be raw material with flake graphite, the improvement reported by W.S.Hummers Jr., R.E.Offeman, Preparation of graphitic oxide, J.Am.Chem.Soc.80 (6) (1958) 1339 prepared by the two-step method; the ionic liquid used is 1,2-ethylenediamine trifluoromethanesulfonate, and the porous graphene material is prepared:

[0037] Step 1: Weigh 400 mg of lyophilized GO powder, dissolve it in 40 mL of distilled water, and disperse it by ultrasonic for 1 h to make it fully dispersed to form a graphene oxide aqueous solution, add 1 mL of hydrogen peroxide solution with a mass concentration of 30% drop by drop, and Fully stir for 2h;

[0038] Step 2: Add 240 mg of 1,2-ethylenediamine trifluoromethanesulfonate ionic liquid dropwise to the dispersion obtained in Step 1, and stir thoroughly for 2 hours;

[0039] Step 3: Transfer the mixed solution obtained in the above steps to a 50mL hydrothermal reaction kettle, and react at 160°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com