Production method of large-scale rice wheat straw microorganism feed

A microbial feed, rice and wheat straw technology, applied in the field of new microbial roughage, can solve problems such as waste, limited lignin degradation, and large loss of bacterial enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

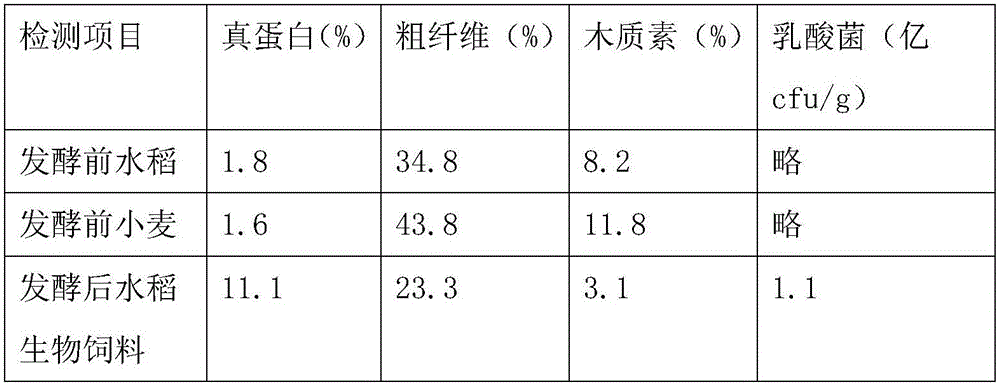

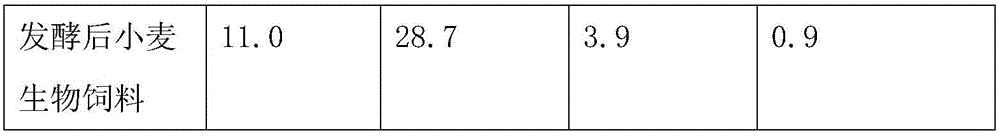

Examples

Embodiment 1

[0074] Embodiment 1: pre-production of white rot fungus enzyme preparation

[0075] (1) White rot fungus culture medium.

[0076] Slant medium and plate medium: 200g potato, 20g sucrose, 20g agar, in 1L constant volume, pH 5.0, sterilized at 110°C for 30min. Inoculate and culture at 37°C for 4 days.

[0077] Seed liquid medium: KH 2 PO 4 2g, MgSO 4 0.3g, CaCl 2 0.3g, peptone 5g, yeast extract 3g, wort juice or glucose 3g, ammonium tartrate 1g, dilute to 1L, in which FeSO 4 ·7H 2 O, ZnSO 4 、CuSO 4 ·5H 2 O, MnSO 4 .4H 2 O and CoCl 2 0.001% each, pH 5.5. Add 100ml medium to a 500ml Erlenmeyer flask, and sterilize at 110°C for 30min.

[0078] White rot fungus solid-state fermentation seed culture medium: by weight, cut, shredded and crushed rice and wheat (below 20mm) account for 70% of the medium (calculated as dry material), bran or rice bran accounts for 25%, tartrate amine , ammonium nitrate, ammonium sulfate or ammonium chloride accounted for 0.2%, CaCO 3 1%...

Embodiment 2

[0081] Embodiment 2: the first phase of rice straw fermentation

[0082] (1) Seed medium and production medium of fiber-degrading bacteria such as Neurospora.

[0083] Neurospora and other slant medium and plate medium: 200g potato, 20g sucrose, 20g agar, constant volume 1L, pH 5.0, sterilized at 110°C for 30min. Inoculate and culture at 32°C for 2 days.

[0084] Neurospora and other seed liquid medium: KH 2 PO 4 2g, MgSO 4 0.3g, CaCl 2 0.3g, peptone 5g, yeast extract 3g, wort juice or brown sugar 3g, ammonium sulfate or urea 5g, FeSO 4 ·7H 2 O 0.005g, ZnSO 4 0.0014g, MnSO 4 4H 2 O 0.0016g, CoCl 2 0.002g, dilute to 1L, pH 5.0. Add 100ml medium to a 500ml Erlenmeyer flask, and sterilize at 110°C for 30min.

[0085] Candida utilis slant culture medium and plate culture medium (100ml): glucose 2g, yeast extract 1g, peptone 1g, urea 1g, agar 2g, pH value about 6.0.

[0086] Candida utilis liquid medium: the composition is the same as that of the slant medium, witho...

Embodiment 3

[0093] Embodiment 3: the second phase of rice straw fermentation

[0094] (1) Bacillus culture medium

[0095] Bacillus slant and plate culture medium: peptone 10g, beef extract powder 5g, sodium chloride 5g, agar 15g, glucose 20g, distilled water 1000ml, final pH7.0±0.2. Sterilize at 121°C for 20min.

[0096] Bacillus shake flask seed medium and seed tank medium: beef extract 5.0g / L, peptone 20.0g / L, glucose 5.0g / L, FeCl 2 ·6H 2 O 0.07g / L, MnCl 2 ·7H 2 O 0.01g / L, MgSO 4 ·7H 2 O 0.15g / L, pH 6.5-7.0, sterilized at 110-121°C for 20min.

[0097] (2) Saccharomyces cerevisiae medium

[0098] Yeast slant medium and plate culture medium (100ml): 2g glucose, 1g yeast extract, 2g peptone, 2g agar, pH value about 6.0.

[0099] Shake flask seed medium and liquid seed tank medium: the composition is the same as that of the slant medium, without adding agar.

[0100] (3) The second-stage rice-wheat straw solid-state fermentation medium is composed of the first-stage fermentation p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com