Lithium-manganese-phosphate anode material for lithium-ion power battery and preparing method thereof

A lithium manganese phosphate, power battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems affecting the electrical properties of lithium manganese phosphate products, suppress side reactions, change Fermi level, and improve electronic conductivity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

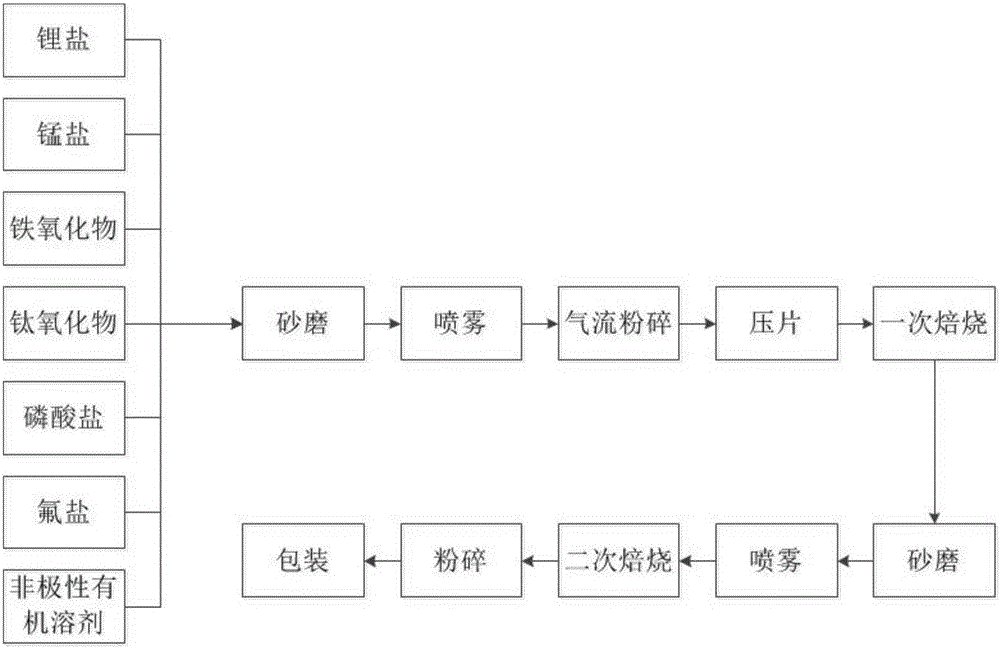

[0028] Such as figure 1 Shown, the preparation method of lithium manganese phosphate lithium positive electrode material for lithium ion power battery of the present invention specifically comprises the steps:

[0029] 1) According to the chemical formula Li 1.02 mn 0.94 Fe 0.05 Ti 0.01 (PO 4 ) 0.99 f 0.01 Weigh lithium carbonate, manganese carbonate, ferrous oxide, titanium dioxide, ammonium dihydrogen phosphate, lithium fluoride, according to the quality of n-hexane: (lithium carbonate + manganese carbonate + ferrous oxide + titanium dioxide + ammonium dihydrogen phosphate + lithium fluoride) Mass=3.0:1 Weigh n-hexane, and weigh ECP600JD according to the carbon content of the final product at 3%;

[0030] 2) Add the above-mentioned substances to a sand mill for sand grinding, and the particle size of the slurry after sand grinding is D 50 = 0.22 μm;

[0031] 3) The above slurry is spray-dried in a nitrogen-protected closed spray dryer, the inlet temperature is 180°C...

Embodiment 2

[0042] A kind of preparation method of manganese phosphate lithium cathode material for lithium-ion power battery, specifically comprises the following steps:

[0043] 1) According to the chemical formula Li 1.05 mn 0.87 Fe 0.1 Ti 0.03 (PO 4 ) 0.98 f 0.02 Weigh lithium hydroxide, manganese carbonate, ferric oxide, titanium dioxide, ammonium dihydrogen phosphate, boron trifluoride, according to the quality of n-hexane: (lithium hydroxide + manganese carbonate + ferric oxide + titanium dioxide + ammonium dihydrogen phosphate + boron trifluoride) mass = 4.0:1 Weigh n-hexane, and weigh ECP600JD according to the carbon content of the final product at 5%;

[0044] 2) Add the above-mentioned substances to a sand mill for sand grinding, and the particle size after sand grinding is D 50 = 0.20 μm;

[0045] 3) The above slurry is spray-dried in a nitrogen-protected closed spray dryer with an inlet temperature of 220°C and an outlet temperature of 100°C;

[0046] 4) Airflow pulv...

Embodiment 3

[0058] A kind of preparation method of manganese phosphate lithium cathode material for lithium-ion power battery, specifically comprises the following steps:

[0059] 1) According to the chemical formula Li 1.08 mn 0.87 Fe 0.1 Ti 0.03 (PO 4 ) 0.99 f 0.01 Weigh lithium acetate, manganese carbonate, ferric oxide, titanium dioxide, lithium dihydrogen phosphate, lithium fluoride, according to the mass of cyclohexane: (lithium carbonate+manganese carbonate+ferric oxide+titanium dioxide+lithium dihydrogen phosphate+fluorine Lithium chloride) quality=4.0:1 takes by weighing cyclohexane, takes by weighing ECP600JD according to 5% of final product carbon content;

[0060] 2) Add the above-mentioned substances to a sand mill for sand grinding, and the particle size after sand grinding is D 50 = 0.21 μm;

[0061] 3) The above slurry is spray-dried in a nitrogen-protected closed spray dryer with an inlet temperature of 220°C and an outlet temperature of 100°C;

[0062] 4) Airflo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com