Preparation method of plant-oil-based polyurethane composites modified by dual-layer cage type silsesquioxane

A technology of silsesquioxane and modified vegetable oil, which is applied in the field of preparation of double-layer cage silsesquioxane modified vegetable oil-based polyurethane composite materials, can solve the problems of difficult biodegradation and toxicity, and achieve thermal stability And the effect of water resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Preparation of soybean oil polyol: Add 100g of soybean oil and 43.4g of ethylene glycol into a 250mL single-necked flask, and add 0.14g of fluoboric acid while stirring. After reacting at 98°C for 2 hours, cool to room temperature, extract with ethyl acetate, wash the upper layer solution with saturated NaCl solution and deionized water for 3 times, and evaporate the obtained solution in vacuum at 0.8MPa and 80°C to obtain the desired soybean oil polyols;

[0029] According to the measuring method of hydroxyl value, record its hydroxyl value to be 192mg KOH / g.

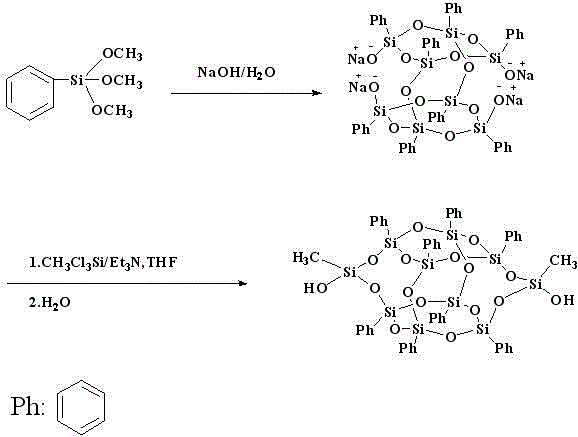

[0030] (2) Preparation of double cage silsesquioxane DDSQ:

[0031] Hydrolysis of phenyltrimethoxysilane under alkaline conditions to generate incompletely condensed DDSQ tetraol sodium salt Na 4 o 14 Si 8 (C 6 h 5 ) 8 : Add 35g of phenyltrimethoxysilane, 150mL of isopropanol, 5g of deionized water and 6g of solid NaOH in sequence in a flask equipped with a condenser and magnetic stirring, reflux at 7...

Embodiment 2

[0060] (1) Preparation of vegetable oil-based polyol: the same as in Example 1.

[0061] (2) Preparation of double cage silsesquioxane DDSQ: the same as in Example 1.

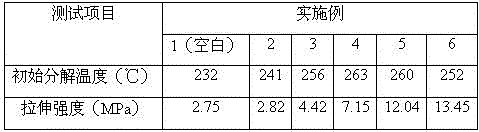

[0062] (3) Preparation of vegetable oil-based polyurethane composite material: 4 g of soybean oil polyol, 1.98 mL of IPDI and 160 μL of stannous octoate were added to a 100 mL three-neck flask, and 30 mL of ethyl acetate was added under stirring. Install the condenser tube, in N 2 Under the atmosphere, after reacting at 80°C for 2 hours, the isocyanate value after the reaction was titrated by the di-n-butylamine toluene method. After calculating the chain extension coefficient of 1.05, add 0.2g DDSQ and 0.844g chain extender 1,4-butanediol, 80 The reaction was continued for 2 h at ℃ to obtain a polyurethane composite solution.

[0063] (4) Drying to form a film: apply the polyurethane composite solution prepared in step (3) on a polytetrafluoroethylene board and let it stand for 10 hours. Let the solvent ethy...

Embodiment 3

[0065] (1) Preparation of vegetable oil-based polyol: the same as in Example 1.

[0066] (2) Preparation of double cage silsesquioxane DDSQ: the same as in Example 1.

[0067] (3) Preparation of vegetable oil-based polyurethane composite material: 4 g of soybean oil polyol, 1.98 mL of IPDI and 160 μL of stannous octoate were added to a 100 mL three-neck flask, and 30 mL of ethyl acetate was added under stirring. Install the condenser tube, in N 2 Under the atmosphere, after reacting at 80°C for 2 hours, the isocyanate value after the reaction was titrated by the di-n-butylamine toluene method. After calculating the chain extension coefficient of 1.05, add 0.4g DDSQ and 0.704g chain extender 1,4-butanediol, 80 The reaction was continued for 2 h at ℃ to obtain a polyurethane composite solution.

[0068] (4) Drying to form a film: apply the polyurethane composite solution prepared in step (3) on a polytetrafluoroethylene board and let it stand for 12 hours, let the solvent ethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com