Ceramic grinding ball for cement ball mill and preparation method thereof

A technology for cement balls and grinding balls is applied in the field of preparation of ceramic grinding balls for cement ball mills. less confusing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

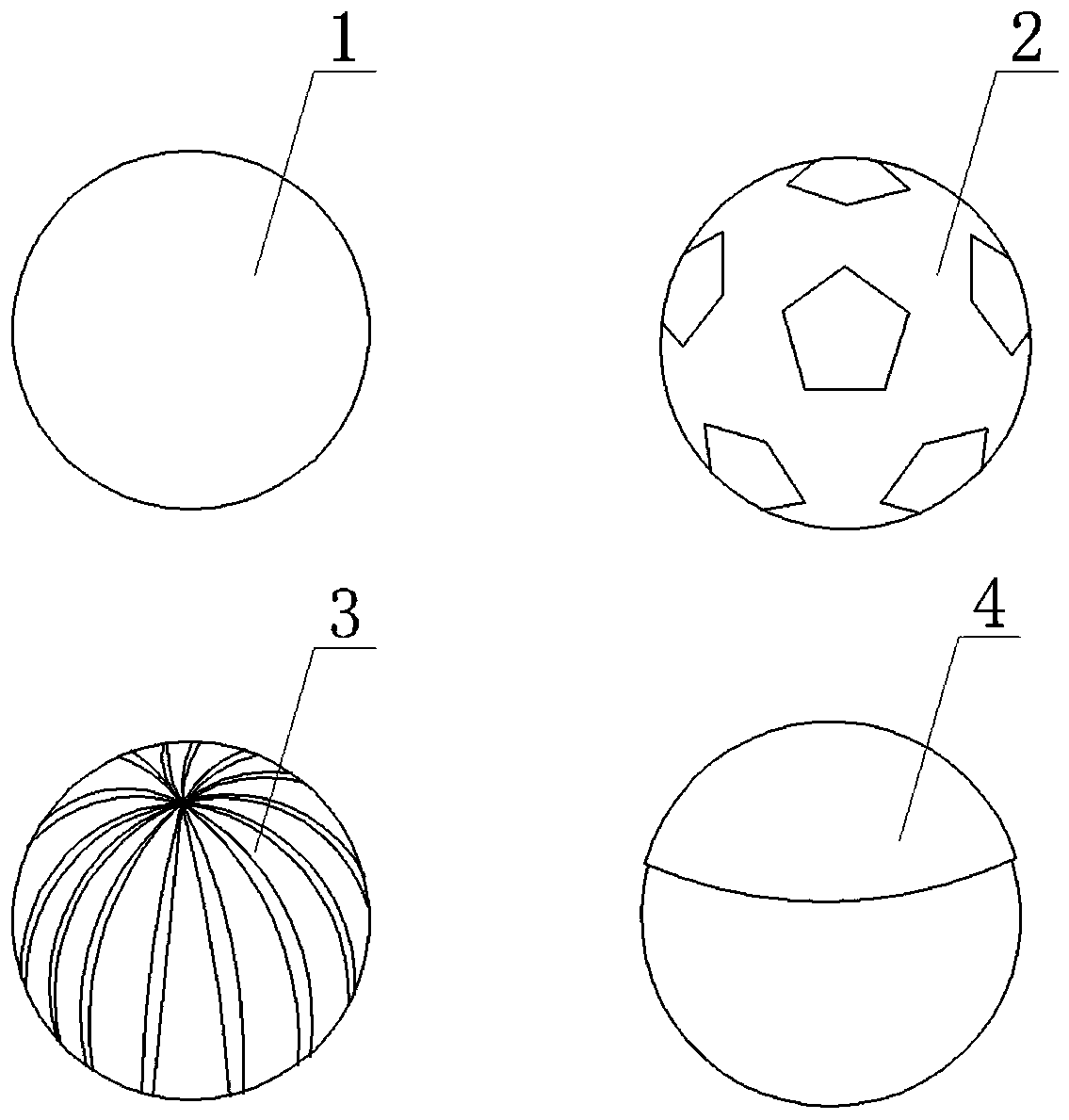

Image

Examples

Embodiment 1

[0031] The ceramic grinding ball used in the cement ball mill contains 92% of alumina, 0.5% of ferric oxide, 1% of kaolin, 2% of silicon carbide, 1.5% of titanium dioxide, 1% of titanium carbide, and 2% of molybdenum disulfide by weight percentage. Method preparation:

[0032] (a) Batching: get all ingredients by weight percentage; configure PVA solution simultaneously, proportioning is PVA:water=8:100;

[0033] (b) Ball milling:

[0034] (b1) Primary grinding: Add the ingredients calculated in step (a) to the primary grinding equipment, and add ball stones and water (the primary grinding balls can be Φ30-Φ50mm 92-high alumina isostatic balls, the same below) , the ratio is material: ball: water=1:2.5:0.7, stop grinding to slurry fineness D90≤8 micron, cross 40 mesh sieves and go out grinding;

[0035] (b2) Fine grinding: Add the slurry obtained in step (b1) into the fine grinding equipment, and add ball stones and water (fine grinding ball stones can be 92-high alumina isos...

Embodiment 2

[0044] The ceramic grinding ball used in the cement ball mill contains 95% of alumina, 0.5% of ferric oxide, 0.8% of kaolin, 0.6% of silicon carbide, 2% of titanium dioxide, 0.8% of titanium carbide, and 0.3% of molybdenum disulfide by weight percentage. Method preparation:

[0045] (a) Batching: get all ingredients by weight percentage; configure PVA solution simultaneously, proportioning is PVA:water=7:100;

[0046] (b) Ball milling:

[0047] (b1) Primary grinding: Add the ingredients calculated in step (a) to the primary grinding equipment, and add ball stones and water in a ratio of material: ball: water = 1:2.5:0.75, until the slurry fineness D90≤8 Micron stop grinding, pass through a 40-mesh sieve for grinding;

[0048] (b2) Fine grinding: Add the slurry obtained in step (b1) to the fine grinding equipment, and add ball stones and water in a ratio of material: ball: water = 1:3:0.75, until the fineness of the slurry is D50≤1.5 microns 、Stop grinding after D90≤3.2 micr...

Embodiment 3

[0057] The ceramic grinding ball used in the cement ball mill contains 92% of alumina, 2% of ferric oxide, 3% of kaolin, 0.2% of silicon carbide, 1.5% of titanium dioxide, 0.8% of titanium carbide, and 0.5% of molybdenum disulfide by weight percentage. Method preparation:

[0058] (a) Batching: get all ingredients by weight percentage; configure PVA solution simultaneously, proportioning is PVA:water=10:100;

[0059] (b) Ball milling:

[0060] (b1) Primary grinding: Add the ingredients calculated in step (a) to the primary grinding equipment, and add ball stones and water in a ratio of material: ball: water = 1:2.5:0.72, until the slurry fineness D90≤8 Micron stop grinding, pass through a 40-mesh sieve for grinding;

[0061] (b2) fine grinding: add the slurry obtained in step (b1) into the fine grinding equipment, and add ball stones and water in a ratio of material: ball: water = 1: 2.5: 0.75, until the fineness of the slurry is D50≤1.5 microns 、Stop grinding after D90≤3.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com