Fireproof door core board and a preparation method thereof

A fire door core board and admixture technology, applied in fire doors, windows/doors, ceramic products, etc., can solve the problems of low slag strength, easy peeling, long production cycle, etc., to improve mechanical properties and water resistance , Excellent comprehensive performance, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The present invention also relates to a preparation method of a magnesium oxysulfide cement foamed fireproof door core board, comprising the following steps: weighing raw materials in proportion, mixing and stirring magnesium sulfate, magnesium oxide, additives and water, adding fillers and continuing stirring to obtain cement slurry , pouring hydrogen peroxide into the cement slurry, stirring, pouring into the mold, standing still, demolding, cutting, and curing for 3 to 7 days to obtain the magnesium oxysulfide foamed fireproof door core board.

[0058] Among them, magnesium sulfate, magnesium oxide, additives and water are mixed and stirred for 5-10 minutes; hydrogen peroxide is quickly poured into the slurry at a stirring speed of 300-500 rpm, and the stirring time is 20s-60s.

[0059] Preferably, the abrasive tool used in the present invention is two stainless steel molds that can be spliced, which are spliced by flanges, and the bottom is a pouring port for pouri...

Embodiment 1

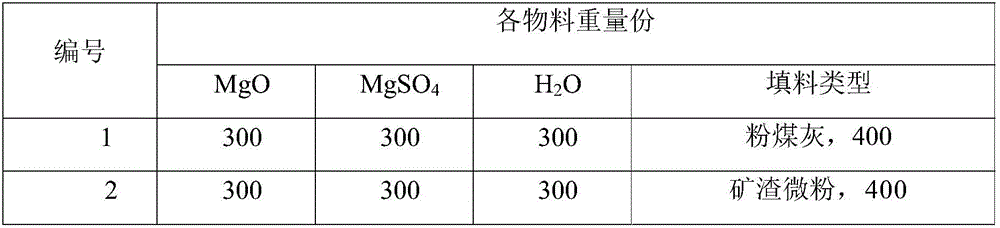

[0072] The proportioning ratio of each raw material in the present embodiment is shown in Table 2:

[0073] Table 2: The formula (parts by weight) of magnesium oxysulfide cement

[0074]

[0075] Foaming is carried out with hydrogen peroxide as foaming agent, the cement mixture (in 1000 parts) listed above and the admixture shown in Table 3 are stirred for 20 minutes to obtain foaming material, which is poured in the door core board mold, And it was maintained at normal temperature and pressure for 7 days before the experiment. The foaming agent addition ratio is shown in Table 4.

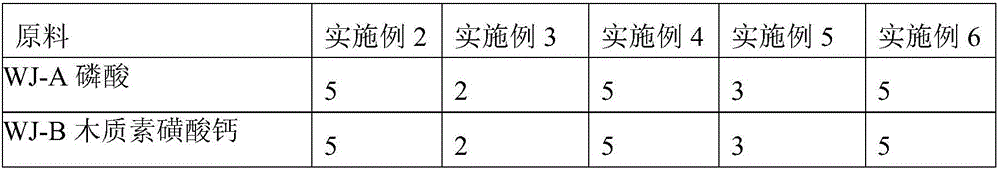

[0076] Table 3: The formula (parts by weight) of admixture

[0077] Admixture

[0078] Table 4 Hydrogen peroxide addition ratio (parts by weight)

[0079] Test No.

[0080] Table 5 Comparison of performance parameters

[0081] performance

[0082] It can be seen from Table 5 that the fire door core board of the embodiment of the present invention has excellent p...

Embodiment 2~6

[0084] Using slag fine powder as filler, the fire door core board was prepared according to the method in Example 1. The proportioning ratio of each raw material is shown in Table 6 and Table 7:

[0085] Table 6: The formula (parts by weight) of magnesium oxysulfide cement

[0086] raw material

Example 2

Example 3

Example 4

Example 5

Example 6

MgO

240

360

420

450

480

MgSO 4

300

300

300

300

300

h 2 o

240

360

400

450

600

filler

300

400

900

1200

150

30

120

75

60

80

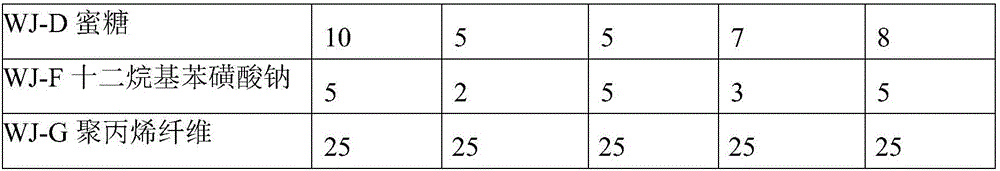

[0087] Add the above magnesium oxysulfide cement mixture (by 1000 parts by weight) to the admixture shown in Table 7 by weight.

[0088] Table 7: The formula (parts by weight) of admixture

[0089]

[0090]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com