Sisal hemp carpet and production method thereof

A production method and sisal technology, applied in the field of sisal carpet and its production, can solve the problems of inconvenient pavement design, inconvenient construction, rigid design, etc., and achieve the goal of improving adsorption capacity, preventing dust from flying, and keeping the air clean Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment one: the present embodiment is a sisal carpet.

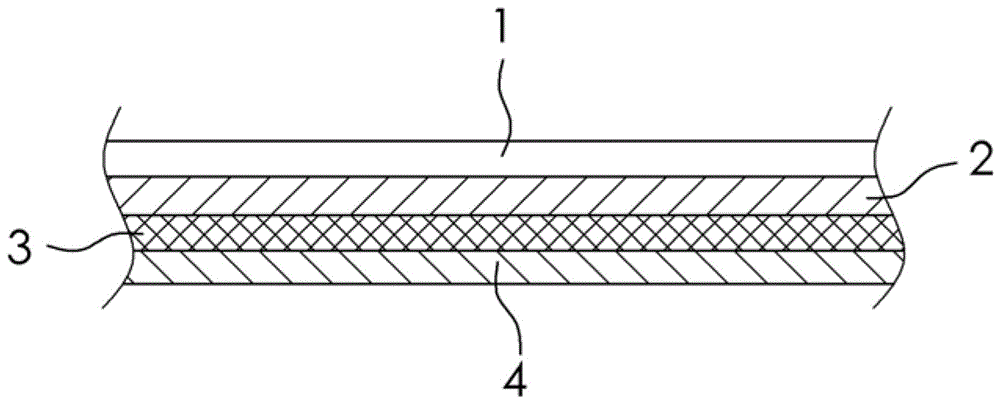

[0035] like figure 1 As shown, a sisal carpet at least includes a sisal weaving layer 1, an adhesive layer 2 and a reinforcing layer 3 stacked in sequence, the adhesive layer 2 is fixedly arranged on the sisal weaving layer 1, and the reinforcing layer 3 It is fixedly arranged on the other side of the adhesive layer 2 (that is, the other side of the side where the adhesive layer 2 is in contact with the sisal weaving layer 1).

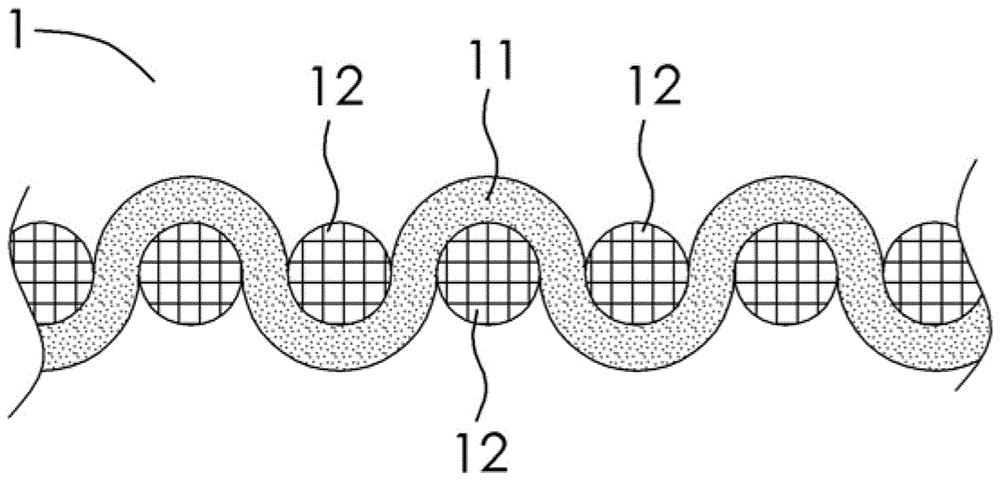

[0036] like figure 2 As shown, the sisal weaving layer 1 is formed by interweaving the veil 11 made of sisal fiber and the weft sand 12 made of sisal fiber.

[0037] Back glue layer 2 can be the coating of PVC latex, also can be the coating of asphalt. Specifically, the adhesive layer 2 is a coating of PVC latex with a thickness of 1.2mm. The back glue layer 2 can further improve the strength and friction resistance of the sisal carpet, and can also improve the elasticity of the si...

Embodiment 2

[0041] Embodiment two: present embodiment is the production method of sisal carpet.

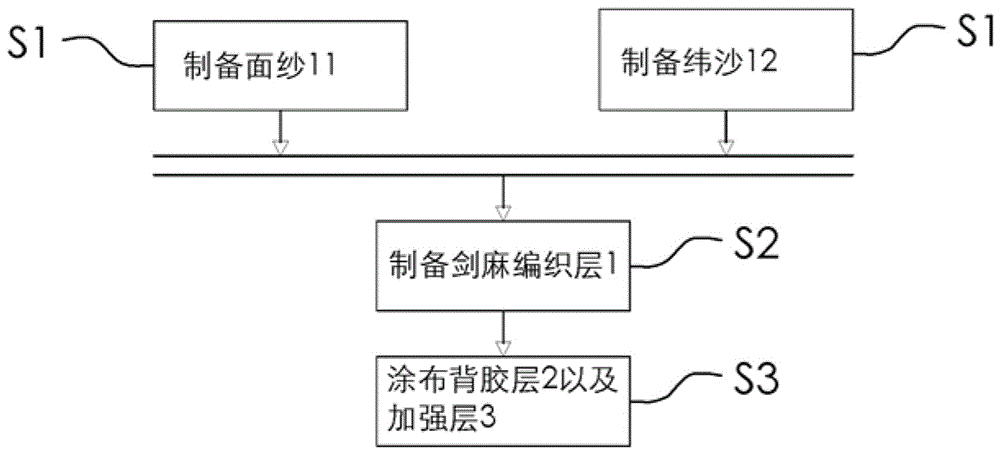

[0042] like image 3 Shown, the production method of sisal carpet comprises the following steps:

[0043] Step 1: S1, preparing the veil 11, softening the sisal fiber with softened sesame oil and ancient oil, and making the veil 11 on the spinning machine for standby; preparing weft sand 12, softening the sisal fiber with softened sesame oil and ancient oil After softening, weft sand 12 is made on the spinning machine for subsequent use;

[0044] Step 2: S2, preparing the sisal weaving layer 1, weaving the veil 11 and the weft sand 12 on the weaving machine to form the sisal weaving layer 1, and set aside;

[0045] Step 3: S3, coating the adhesive layer 2 and the reinforcing layer 3, coating the PVC soft glue on the sisal weaving layer 1 to form the adhesive layer 2, coating the glass fiber non-woven fabric to form the reinforcing layer 3, and drying Drying and cooling; in this step, the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com