Automobile capable of producing hydrogen fuel by reforming ethyl alcohol water vapor through automobile exhaust waste heat

A technology of automobile exhaust and water vapor, applied in gaseous engine fuel, fuel cell, hydrogen, etc., can solve problems such as waste, large volume, corrosion of automobile metal copper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

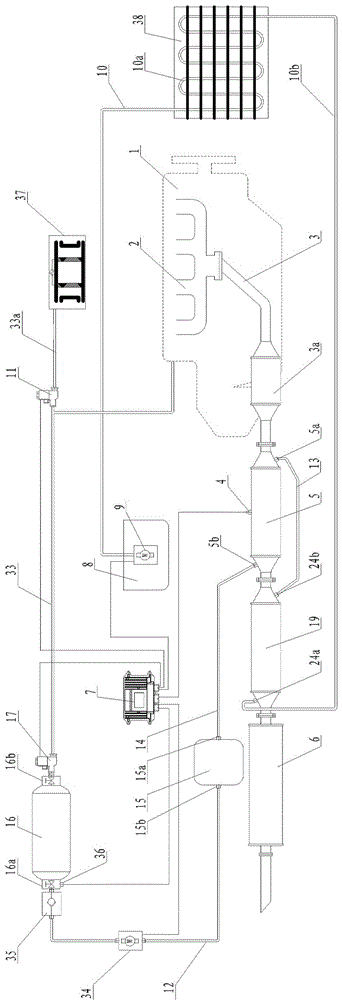

[0071] The present invention relates to a kind of automobile that utilizes the waste heat of automobile exhaust to reform ethanol water vapor to produce hydrogen fuel, which should include the chassis, body, power transmission mechanism, walking system, steering system, braking system, lighting system, control system, etc. System and other conventional structures. This embodiment focuses on the hydrogen fuel delivery pipelines, exhaust emission devices of automobiles that can use hydrogen as fuel, and the device that uses the waste heat of automobile exhaust to reform ethanol water vapor to produce hydrogen fuel.

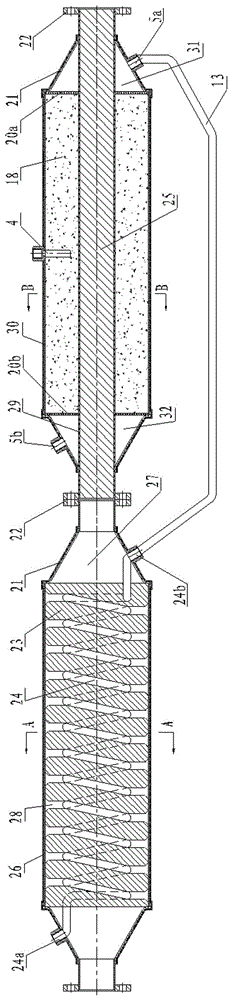

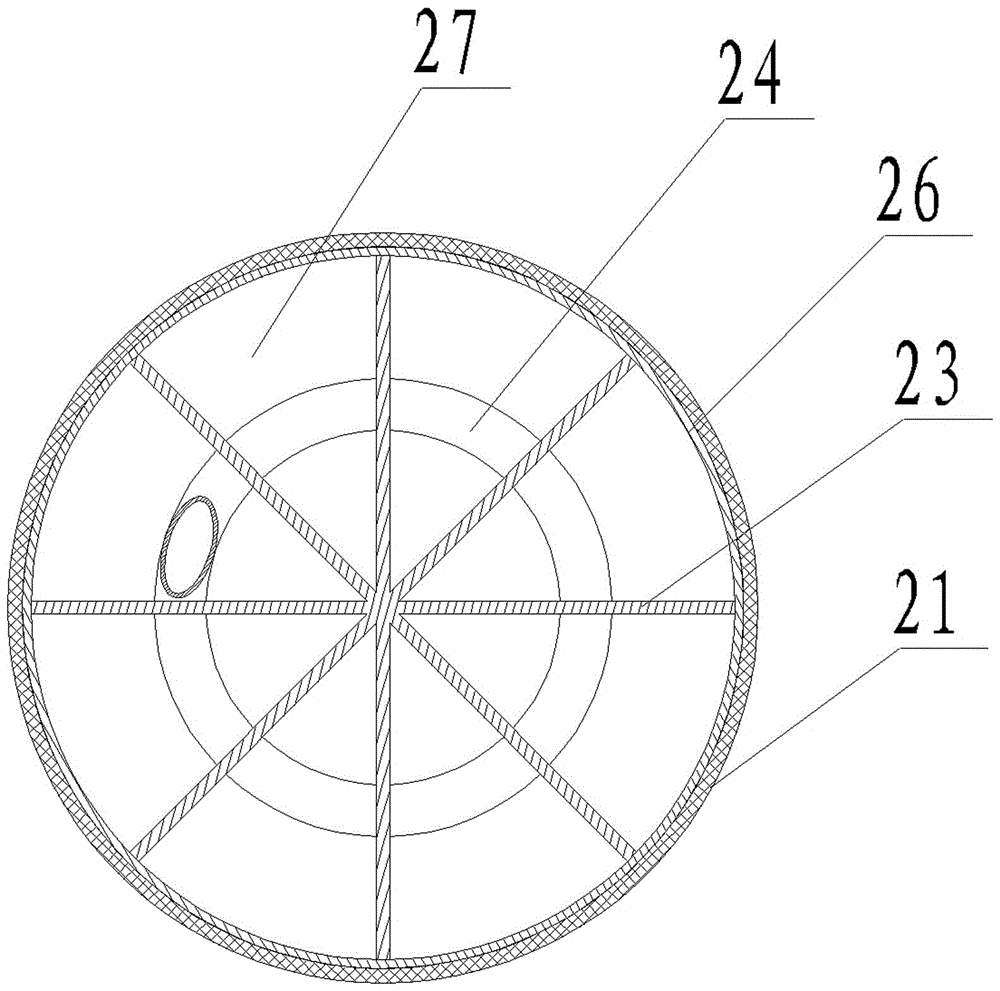

[0072] see Figure 1 to Figure 4, a kind of automobile that utilizes the waste heat of automobile exhaust to reform ethanol water vapor to produce hydrogen fuel, including the engine arranged on the automobile, the exhaust manifold 2 of the engine 1 is connected to the exhaust pipe 3, and the automobile catalytic converter is installed on the exhaust pipe 3 Convert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com