Ball stud steel of automobile steering system and manufacturing method thereof

A technology of automobile steering system and manufacturing method, which is applied in the field of non-quenched and tempered free-cutting cold-deformed steel for automobile steering system ball pins and its manufacturing field, which can solve the problems of lack of systematic and comprehensive research, unstable performance of cold-deformed parts, and constraints on cold-deformation. Market application of micro-alloyed non-quenched and tempered steel for deformation, etc., to achieve the effect of reducing precipitation strengthening effect, excellent cutting performance, and excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

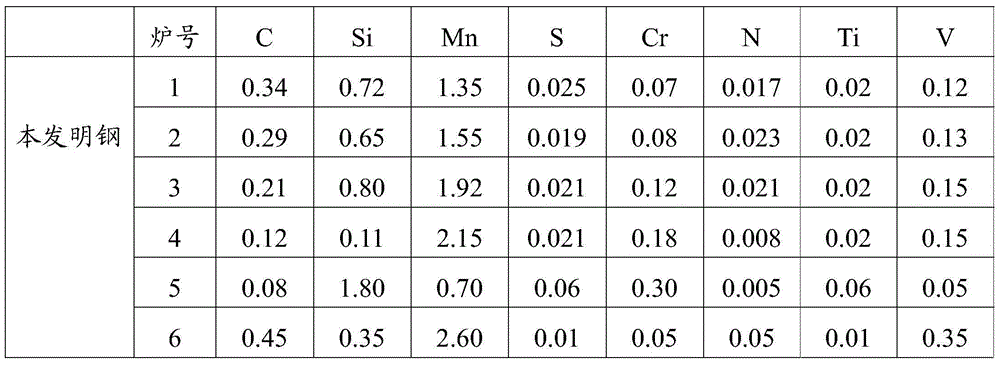

[0051] The chemical composition of the smelted billet is shown in Table 1, which is C0.34%, Si0.72, Mn1.35%, S0.025%, Cr0.07%, V0.12%, Ti0.02%, N0.017%, The balance is Fe and unavoidable impurities. After refining, it is continuously cast into a 160 square billet, the continuous casting degree is 1.4, the soaking temperature of the billet is 1100°C, the heating time is 250min, the starting rolling temperature is 1000°C, the final rolling temperature is 925°C, and the cumulative rolling reduction is controlled to be no less than 80%, the spinning temperature is 900°C; after spinning, the upper Steyr slow cooling is controlled by wire, the cooling speed is 1.5°C / s, the coil is cooled to below 400°C, cooled naturally and packed in bundles. The grain size of the hot-rolled material is 9.0, the yield strength is 550MPa, the tensile strength is 820MPa, and the elongation is 23%.

Embodiment 2

[0053] The chemical composition of the smelted billet is shown in Table 1, which is C0.29%, Si0.65, Mn1.55%, S0.019%, Cr0.08%, V0.13%, Ti0.02%, N0.023%, The balance is Fe and unavoidable impurities. After refining, it is continuously cast into 160 billet. The soaking temperature of the continuous casting billet is 1150°C, the heating time is 250min, the starting rolling temperature is 1000°C, and the final rolling temperature is 900°C. The silk temperature is 900°C; after silk spinning, the Steyr slow cooling line controls the cooling, the cooling speed is 0.65°C / s, the coil is cooled to below 400°C, cooled naturally and bundled for packaging. The grain size of the hot-rolled material is 8.5, the yield strength is 590MPa, the tensile strength is 780MPa, and the elongation is 28%.

Embodiment 3

[0055] The chemical composition of the smelted billet is shown in Table 1, which is C0.21%, Si0.80, Mn1.92%, S0.021%, Cr0.12%, V0.15%, Ti0.02%, N0.021%, The balance is Fe and unavoidable impurities. After refining, the slab is continuously cast, the soaking temperature of the continuous casting slab is 1100°C, the heating time is 250min, the starting rolling temperature is 1000°C, and the final rolling temperature is 870°C. The temperature is 900°C; after spinning, the cooling rate is 0.65°C / s, cooled to below 400°C and collected into coils, cooled naturally and packed in bundles. The grain size of the hot-rolled material is 8.0, the yield strength is 490MPa, the tensile strength is 740MPa, and the elongation is 33%.

[0056] The chemical composition wt% of the embodiment of table 1, the balance is iron and impurities

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com