Pt doped phosphatizing cobalt bead catalyst carried by methanol carbon dioxide and preparation method of Pt doped phosphatizing cobalt bead catalyst

A particle catalyst, cobalt phosphide technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the limitations of commercial development of methanol fuel cells, Pt/C catalyst poisoning, battery cycle life It can achieve good anti-methanol oxidation intermediate product poisoning performance, improve electrocatalytic activity and stability, and reduce the amount of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, comprises the following steps:

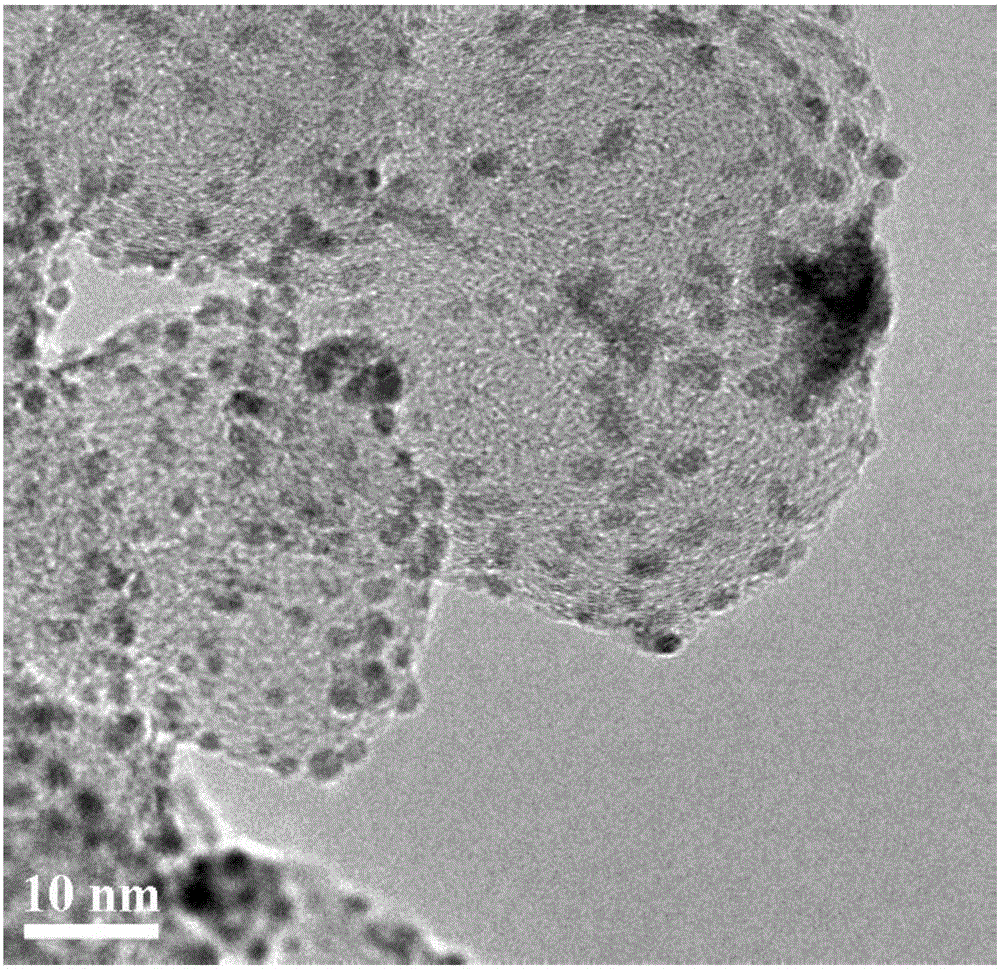

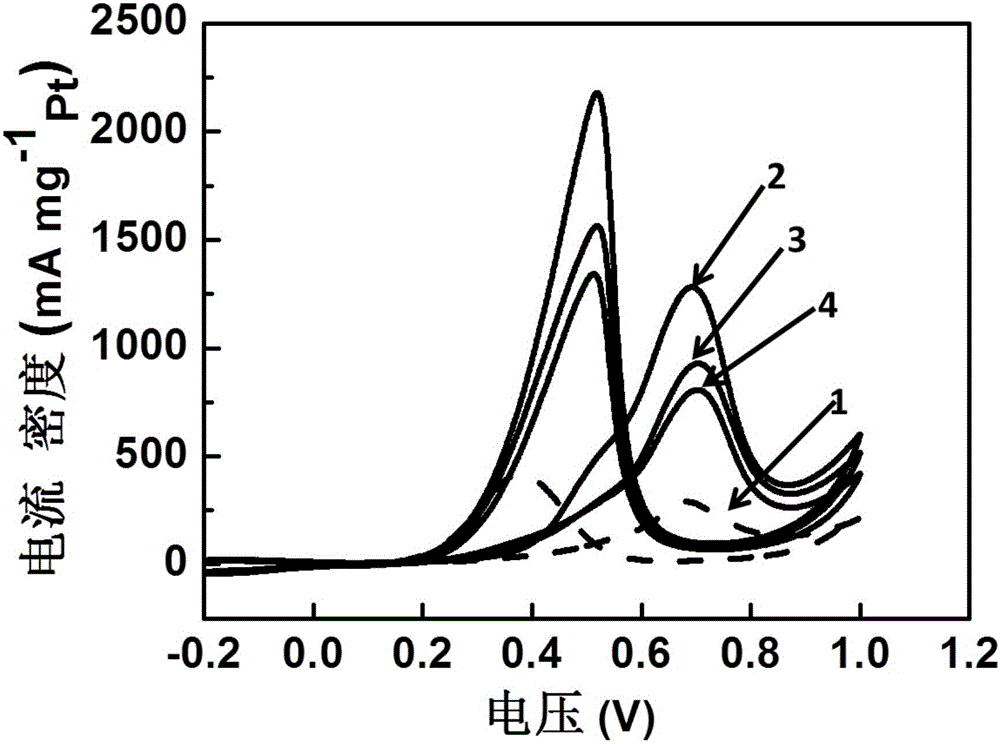

[0024] Add 50 mg of carbon black material to a mixed solution of 48 mL of absolute ethanol and 1 mL of deionized water, and ultrasonically treat the carbon black material to fully disperse in the solution; add 83 mg of cobalt acetate tetrahydrate to the above solution, and stir to fully dissolve it in Then add 1mL of concentrated ammonia water with a mass concentration of 28% to the solution, heat and reflux at 80°C for 14h to obtain a carbon-supported cobalt complex solution; Filter and wash to remove other remaining ions, and fully dry in a vacuum oven at 60°C to obtain a carbon-supported cobalt tetroxide material; mix it with sodium hypophosphite at a ratio of 1:5, grind it to a uniform powder, and transfer it to a nitrogen-filled In a high-temperature tube furnace, heated to 300°C to fully phosphate tricobalt tetroxide to obtain a CoP / C material; the CoP / C was dispersed in a mixed solution of 45mL ethylene glycol and 15...

Embodiment 2

[0026] Embodiment 2, comprises the steps:

[0027] Add 50mg of carbon black material to the mixed solution of 48mL of absolute ethanol and 1mL of deionized water, and ultrasonically treat the carbon black material to fully disperse in the solution; add 97mg of cobalt nitrate hexahydrate to the above solution, stir to make it fully dissolved Add 1mL of concentrated ammonia water with a mass concentration of 28%, and heat and reflux at 80°C for 14h to obtain a carbon-supported cobalt complex solution; transfer the solution to a hydrothermal reactor and heat it at 140°C for 2h, then filter and wash Remove other remaining ions, and fully dry in a vacuum oven at 60°C to obtain a carbon-supported cobalt tetroxide material; mix it with sodium hypophosphite at a ratio of 1:5, grind it to a uniform powder, and transfer it to a high-temperature tube filled with nitrogen In a type furnace, heated to 300°C to fully phosphate tricobalt tetroxide to obtain the carbon-supported cobalt phosph...

Embodiment 3

[0029] Embodiment 3, comprises the following steps:

[0030] 40mg of carbon black material was added to 49mL of absolute ethanol solution, and ultrasonic treatment made the carbon black material fully dispersed in the solution; 113mg of cobalt nitrate hexahydrate was added to the above solution, stirred to make it fully dissolved, and then 1.2mL of mass concentration was added. 28% concentrated ammonia water was heated and refluxed at 90°C for 15 hours to obtain a carbon-supported cobalt complex solution; the solution was transferred to a hydrothermal reaction kettle and heated at 150°C for 4 hours, filtered and washed to remove other remaining ions, Fully dry in a vacuum oven at 80°C to obtain a carbon-supported cobalt tetroxide material; mix it with sodium hypophosphite at a ratio of 1:5, grind it to a uniform powder, transfer it to a high-temperature tube furnace filled with argon, and heat Phosphate tricobalt tetroxide at 350°C to obtain CoP / C material; disperse CoP / C in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com