High Curie temperature material and preparation method

A room temperature, concentration technology, applied in the direction of magnetic materials, inorganic material magnetism, metal material coating technology, etc., can solve the problem of insufficient Curie temperature, and achieve the effect of wide temperature application range, uniform organization, and strong structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

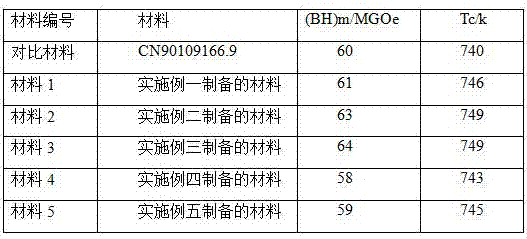

Examples

Embodiment 1

[0026] The preparation method of the high Curie temperature material of the present invention, the method comprises the following steps:

[0027] 1) According to the following mass percentage ingredients: Nd 22%, Ce 6.2%, Lu 0.6%, Gd 3.6%, B 3%, Yb 0.15%, In 0.45%, P 0.014%, Ni 0.45%, and the rest is Fe; Nd , Ce , Lu , Gd , Yb , In , Ni are added in the form of pure element, B is added in the form of iron-boron alloy containing 25% by mass of B, Si is added in the form of pure single crystal silicon, and P is added in the form of phosphorus with a mass fraction of 25%. % is added in the form of phosphorus-iron alloy, and the balance Fe is added in the form of pure metal;

[0028] 2) Add the above-mentioned prepared raw materials into the crucible in the vacuum induction furnace, heat to 1495°C, keep it warm for 25 minutes, then pour it into the ingot mold, and obtain the rare earth alloy ingot after natural cooling;

[0029] 3) The above-mentioned rare earth-containing alloy ...

Embodiment 2

[0035] The preparation method of the high Curie temperature material of the present invention, the method comprises the following steps:

[0036] 1) According to the following mass percentage ingredients: Nd 24%, Ce 8.8%, Lu 0.9%, Gd 4.4%, B7%, Yb 0.30%, In0.60%, P 0.04%, Ni 0.60%, and the rest is Fe; where Nd , Ce, Lu, Gd, Yb, In, Ni are added in the form of pure simple substance, B is added in the form of iron-boron alloy containing 25% by mass of B, Si is added in the form of pure single crystal silicon, and P is added in the form of phosphorus with a mass fraction of 25% Fe is added in the form of phosphorus-iron alloy, and the rest Fe is added in the form of pure metal;

[0037] 2) Add the above-mentioned prepared raw materials into the crucible in the vacuum induction furnace, heat to 1530°C, keep it warm for 25 minutes, then pour it into the ingot mold, and obtain the rare earth alloy ingot after natural cooling;

[0038] 3) The above-mentioned rare earth-containing al...

Embodiment 3

[0044] The preparation method of the high Curie temperature material of the present invention, the method comprises the following steps:

[0045] According to the following mass percentage ingredients: Nd 23%, Ce 7.5%, Lu 0.8%, Gd4.0%, B 5%, Yb 0.2%, In0.5%, P 0.025%, Ni 0.52%, the rest is Fe; other conditions And preparation process with embodiment one. The obtained magnetic material contains 0.07% N and 0.20% S by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com