Forming method of thin-walled helical antenna supporting medium tube made of high-temperature-resistant polyimide composite

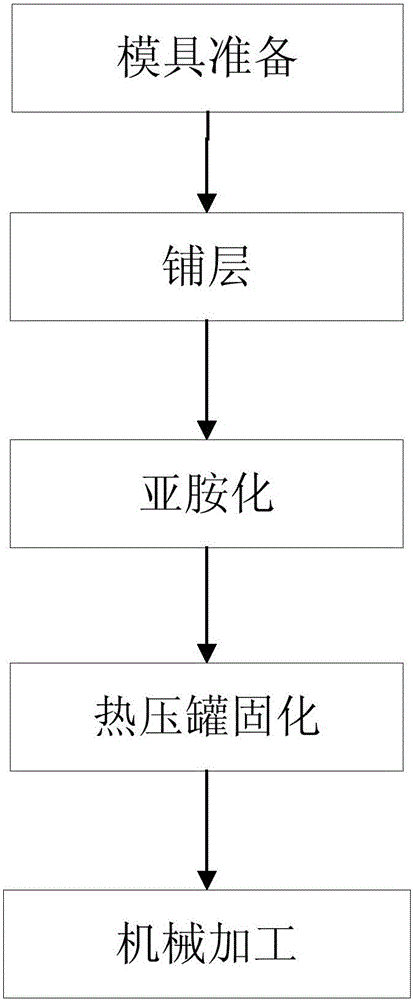

A technology of helical antenna and supporting medium, which is applied in the forming field of high-temperature-resistant polyimide composite material thin-walled helical antenna supporting medium tube, can solve the problems of reducing composite material forming processability and engineering application obstacles, and achieve excellent comprehensive performance , improve the mechanical properties, and fully pressurize the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The resin is PMR type thermosetting polyimide resin, with PEPA (phenylethynyl phthalic anhydride) as the end-capping agent. After imidization, the minimum melt viscosity of the resin is 1000Pa.s (heating rate is 4°C / min). The reinforcement is QW220 quartz fiber twill cloth, the glue content is 48%, and the single layer thickness is 0.20mm.

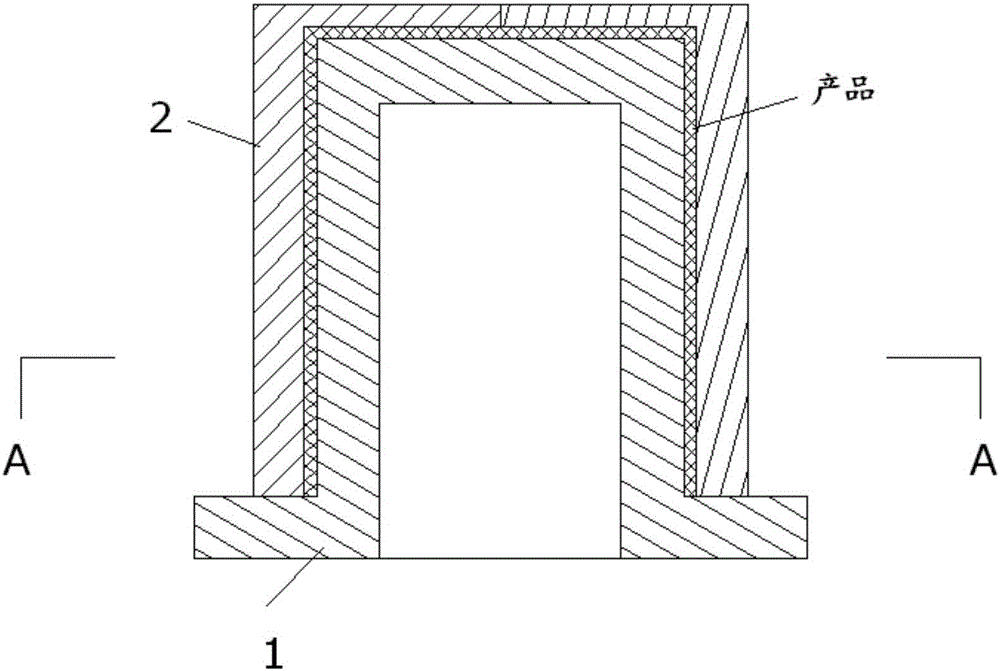

[0057] The thickness of the helical antenna supporting dielectric tube is 2mm, the thickness of the bottom is 2mm, and the number of layers of the barrel and the bottom is 10 layers. Cut the prepreg block according to the design size of the product, and carry out the overall winding and laying on the surface of the male mold 1 to form a cylinder for the helical antenna to support the medium tube. , to complete the layering of the medium pipe;

[0058] Wrap the outer surface of the layer on the male mold 1 with a heat-shrinkable tape as a whole, and carry out imidization in a heating device such as an oven. The imidization process i...

Embodiment 2

[0064] The resin selection is the same as in Example 1, the reinforcement is QW110 quartz fiber twill cloth, the glue content is 50%, and the single layer thickness is 0.10 mm.

[0065] The thickness of the helical antenna supporting dielectric tube is 2mm, the thickness of the bottom is 2mm, and the number of layers of the barrel and the bottom is 20 layers. Cut the prepreg block according to the design size of the product, and carry out the overall winding and laying on the surface of the male mold 1 to form a cylinder for the helical antenna to support the medium tube. , to complete the layering of the medium pipe;

[0066] The outer surface of the laminate material on the male mold 1 is wrapped with a heat shrinkable tape, and imidized in a heating device such as an oven. The imidization process is as follows: heating up to 200°C, pressure 0.6MPa, and holding for 0.5 hours.

[0067] After the imidization is completed, the block female mold 2 and the imidized laminate are ...

Embodiment 3

[0071] The resin selection is the same as in Example 1, the reinforcement is EW220 glass fiber twill cloth, the glue content is 55%, and the single layer thickness is 0.20mm.

[0072] The helical antenna supports the medium tube with a body size of 2mm and a bottom of the tube with a thickness of 2mm. The prepreg block is cut according to the product design size, and the overall winding layer is carried out on the surface of the male mold 1 to form a cylinder for the helical antenna to support the medium tube. The bottom layer of the cylinder is turned down toward the cylinder to overlap the cylinder , to complete the layering of the medium pipe;

[0073] Wrap the outer surface of the laminate material on the male mold 1 with a heat shrinkable tape as a whole, and carry out imidization in a heating device such as an oven. The imidization process is as follows: heating up to 170°C and holding the temperature for 1.5 hours.

[0074] After the imidization is completed, the block...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com