Cobalt selenide/carbon sodium ion battery composite negative electrode material as well as preparation method and application of cobalt selenide/carbon-sodium ion battery composite negative electrode material

A technology of sodium ion battery and negative electrode material, applied in battery electrodes, non-aqueous electrolyte storage batteries, circuits, etc., can solve the problems of synthesis method, performance and application difference, low ionic conductivity and electronic conductivity, and the invention has not yet been reported. , to achieve the effect of environmental friendliness, reducing electrode capacity decay and increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

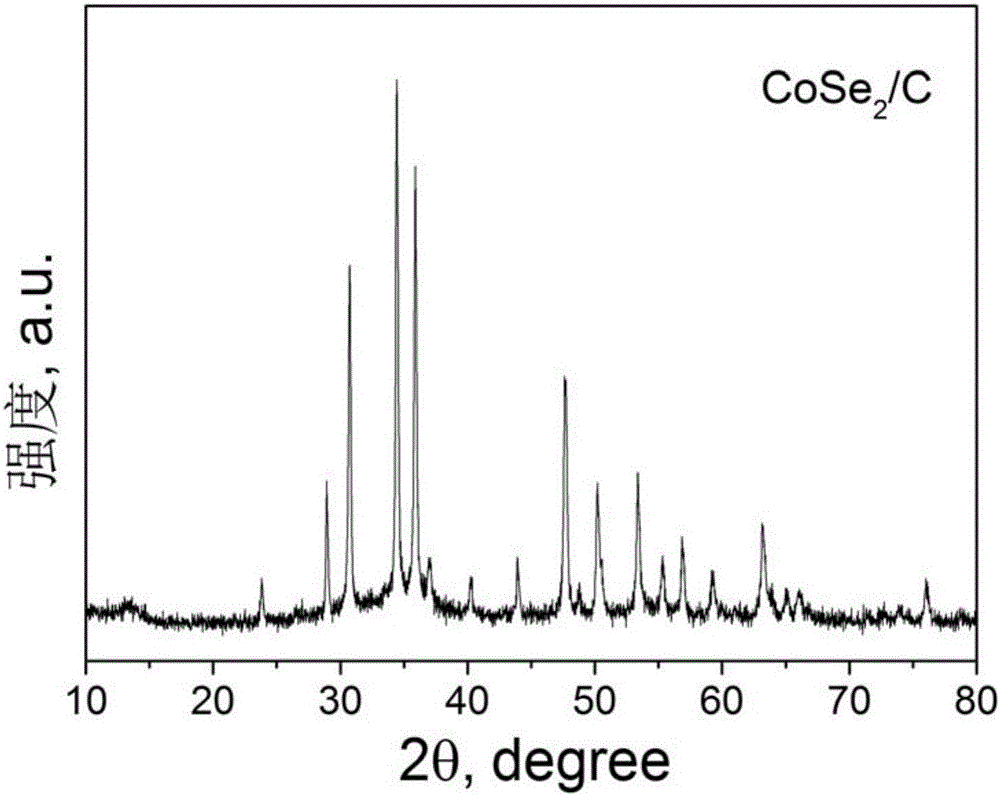

[0027] (1) Weigh 0.587g of cobalt nitrate and 0.32g of selenium powder into a beaker filled with 40ml of deionized water, then mix the selenium source solution and cobalt source solution evenly, then add 0.1g of graphite flakes to the In the mixed solution, after ultrasonication for 2 hours, a dispersion liquid was obtained. The dispersion liquid was put into a reaction kettle, and a hydrothermal reaction was carried out at a temperature of 200° C. for 20 hours. The hydrothermal reaction product is separated from solid to liquid, washed with water and alcohol for 3 times, dried in a vacuum oven at 60°C, and heat-treated at 300°C for 1 hour under a nitrogen protective atmosphere to obtain cobalt selenide / carbon Composite anode materials for sodium ion batteries. X-ray powder diffraction (XRD) analysis shows that the obtained product is cobalt selenide with cubic crystal structure, without any other impurity phases, and has high crystallinity (such as figure 1 shown). It can ...

Embodiment 2

[0030] (1) Weigh 0.5g of cobalt acetate and 0.69g of sodium selenosulfate into a beaker containing 40ml of ethanol, then mix the selenium source solution and cobalt source solution evenly, then add 0.05g of carbon nanotubes Into the mixed solution, ultrasonic 5h, to obtain a dispersion. The dispersion liquid was put into a reaction kettle, and hydrothermally reacted at a temperature of 180°C for 30 hours. Separate the solid-liquid of the hydrothermal reaction product, wash the obtained solid three times with water and alcohol respectively, dry it in a vacuum drying oven at 70°C, and heat-treat at 350°C for 2 hours under a nitrogen protective atmosphere to obtain cobalt selenide / sodium carbon Composite anode materials for ion batteries. XRD analysis shows that the obtained product is cobalt selenide with cubic crystal structure, without any other impurity phase, and has high crystallinity. It can be seen from the SEM image that the composite material is a graphene-coated nano...

Embodiment 3

[0033](1) Weigh 0.53g of cobalt sulfate and 0.32g of sodium selenite into a beaker filled with 40ml of dimethylformamide, then mix the selenium source solution and cobalt source solution evenly, and then add 0.3g of Glucose was added to the mixed solution, and a dispersion was obtained after ultrasonication for 0.5 h. The dispersion liquid was put into a reaction kettle, and hydrothermally reacted at a temperature of 220° C. for 15 hours. The hydrothermal reaction product was separated from solid to liquid, washed three times with water and alcohol respectively, dried in a vacuum oven at 80°C, and heat-treated at 400°C for 3 hours under a nitrogen protective atmosphere to obtain cobalt selenide / carbon Composite anode materials for sodium ion batteries. XRD analysis shows that the obtained product is cobalt selenide with cubic crystal structure, without any other impurity phase, and has high crystallinity. It can be seen from the SEM image that the composite material is a gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com