Low-carbon round steel for agricultural vehicle shock absorber sleeve and converter smelting method of low-carbon round steel

A converter smelting and shock absorber technology, applied in furnaces, electric furnaces, furnace types, etc., can solve problems such as failure to meet user requirements, difficulty in production control, waste of material costs, etc., achieve low inclusion control level, and improve material toughness and heat treatment hardenability, the effect of saving precious alloy Cr elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

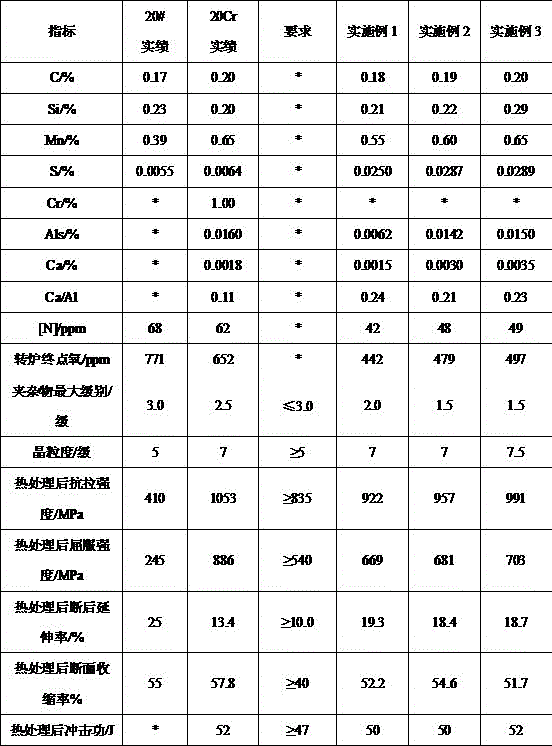

[0023] Embodiment 1, embodiment 2 and embodiment 3 are shown in Table 2 for the chemical composition and weight percentage of the low-carbon structure round steel used for the shock absorber sleeve pipe of agricultural vehicles:

[0024] Table 2 Chemical composition and weight percentage of Examples 1-3 (unit: wt%)

[0025]

C Si mn S als Ca Example 1 0.18 0.21 0.55 0.0250 0.0062 0.0015 Example 2 0.19 0.22 0.60 0.0287 0.0142 0.0030 Example 3 0.20 0.29 0.65 0.0289 0.0150 0.0035

[0026] Example 1:

[0027] Low-carbon structural round steel for shock absorber casings for agricultural vehicles, its Ca / Al is 0.24, and the nitrogen content of the finished product is 42ppm. The smelting process is as follows:

[0028] Converter smelting: End point composition [C]0.17wt%, [P]0.014wt%, oxygen content in converter end point steel 442ppm; tapping time 4.5min, ladle clean, no residual steel residue; Carbon agent, aluminum particl...

Embodiment 2

[0032] Low-carbon structural round steel for shock absorber casings for agricultural vehicles, its Ca / Al is 0.21, and the nitrogen content of the finished product is 48ppm. The smelting process is as follows:

[0033] Converter smelting: End point composition [C] 0.15wt%, [P] 0.013wt%, oxygen content in converter end point steel 479ppm; tapping time 4.5min. The ladle is clean and free of residual steel residues; carburizer, aluminum particles, ferrosilicon manganese, ferrosilicon, synthetic slag, and lime are added sequentially when tapping 1 / 4 of the steel. The amount of aluminum particles added is 0.9kg / ton of steel, and the synthetic slag The amount of added slag is 1.3kg / ton of steel, and the amount of lime added is 1.6kg / ton of steel; double slag blocking operation, the amount of slag lowered is less than 1.5kg / ton of steel; argon blowing starts 3 minutes before tapping. Operation of the argon blowing station behind the furnace: measure temperature and take steel samples ...

Embodiment 3

[0037] Low-carbon structural round steel for shock absorber casings for agricultural vehicles, its Ca / Al is 0.23, and the nitrogen content of the finished product is 49ppm. The smelting process is as follows:

[0038] Converter smelting: End point composition [C] 0.15wt%, [P] 0.020wt%, oxygen content in converter end point steel 497ppm; tapping time 4.5min. The ladle is clean and free of residual steel residues; when tapping 1 / 4 of the steel, the order of adding: recarburizer, aluminum particles, ferrosilicon manganese, ferrosilicon, synthetic slag, lime, in which the amount of aluminum particles added is 1.0kg / ton of steel, synthetic The amount of slag added is 1.3kg / ton of steel, and the amount of lime added is 1.6kg / ton of steel; double slag blocking operation, the amount of slag lowered is less than 1.5kg / ton of steel; argon blowing starts 3 minutes before tapping. Operation of the argon blowing station behind the furnace: measure temperature and take steel samples after b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com