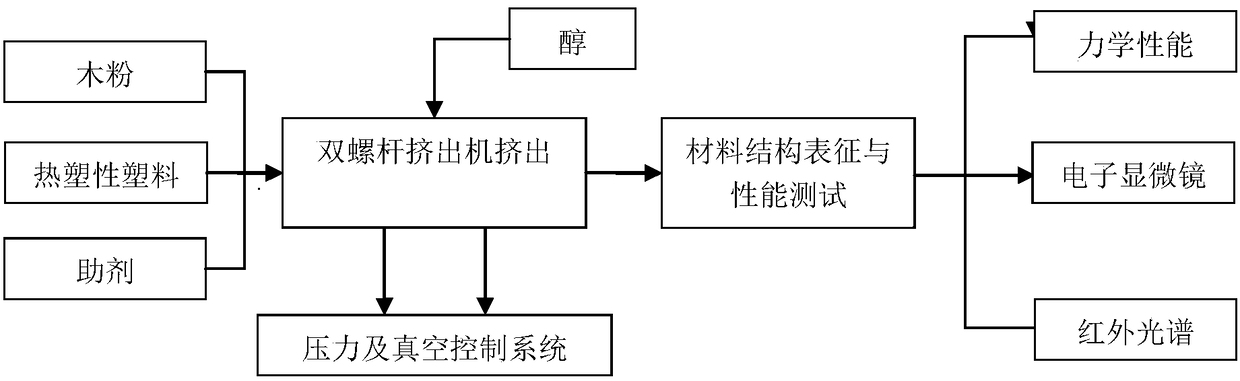

A method for preparing wood-plastic composites by subcritical alcohol extrusion

A wood-plastic composite material and subcritical technology, which is applied in the field of subcritical alcohol extrusion to prepare wood-plastic composite materials, can solve the problems of reducing the interface bonding force of wood-plastic composite materials, and achieve easy automation, low energy consumption, and continuous reaction process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

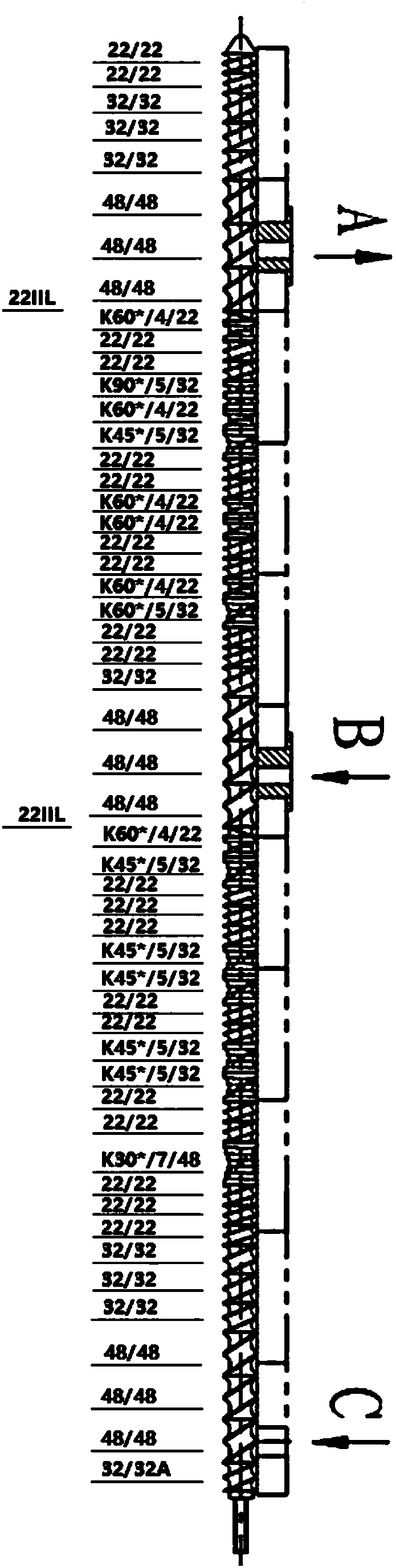

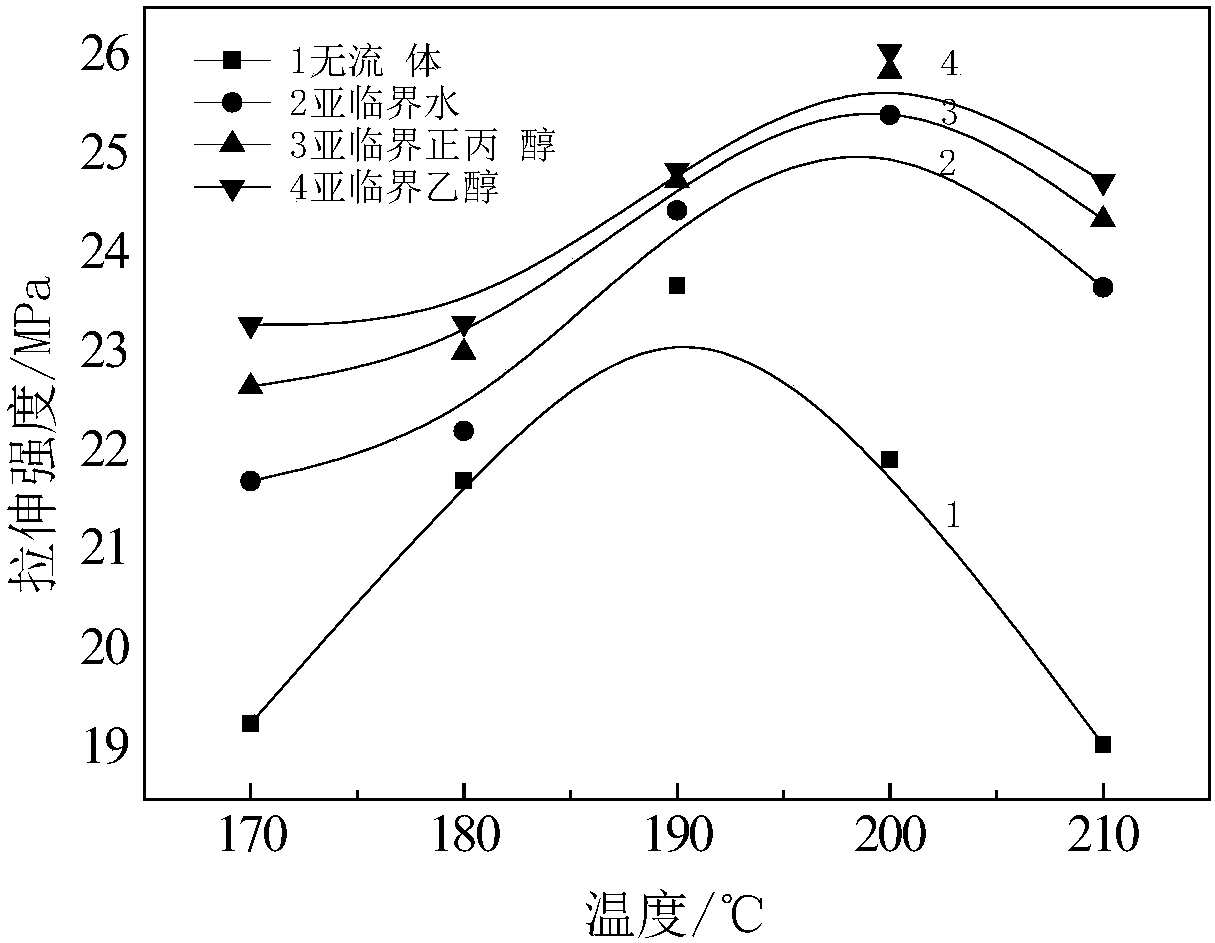

[0057] Embodiment 1: Select 80 mesh eucalyptus wood powder (Shanghai Yuncan Wood Products Co., Ltd.) 560g and PP-T30S (Shaanxi Yanchang (Group) Yan'an Petrochemical Plant) 200g, MAPP-50 (Nanjing Qiangren Plastic Co., Ltd.) 40g , liquid paraffin (Shanghai Lingfeng Chemical Reagent Co., Ltd., chemically pure) 16g, polyethylene wax (Shanghai Jinshan Xingxing Plastic Co., Ltd.) 8g, stearic acid 1801 (Malaysia Natural Oil Chemical Co., Ltd.) 8g, they are mixed with each other. The mixture was fed into a three-stage co-rotating twin-screw extruder with a diameter of 35mm and a length-to-diameter ratio of 44 (Nanjing Coperion-Keya Machinery Equipment Co., Ltd., the extrusion process and screw combination diagram of the extrusion device are shown in the attached figure 1 , attached figure 2 ), the screw speed is controlled at 120rpm, and the extrusion temperature is 170°C (water, 0.80MPa; n-propanol, 1.0MPa; ethanol, 1.60MPa), 180°C (water, 1.00MPa; n-propanol, 1.2MPa; ethanol , 2.0...

Embodiment 2

[0069] Embodiment two: choose 480g of 80 mesh eucalyptus wood flour (Shanghai Yuncan Wood Products Co., Ltd.), 240g of PP-T30S, 80g of MAPP-50, polyethylene wax is 8g, and stearic acid is 8g, and they are mutually Mixing, the mixture is added together in the above-mentioned twin-screw extruder, and its screw speed is 120rpm, temperature is 190 ℃, injects ethanol (2.4MPa) at B metering position of screw structure diagram simultaneously, other conditions are identical with embodiment one.

Embodiment 3

[0073] Embodiment three: choose the 80 order eucalyptus wood flour of 560g (Shanghai Yuncan Wood Products Co., Ltd.), the PP-T30S of 160g, the MAPP-50 of 80g, polyethylene wax is 8g, and stearic acid is 8g, and they are mutually Mixing, the mixture is added together in the above-mentioned twin-screw extruder, and its screw speed is 120rpm, temperature is 190 ℃, injects ethanol (2.4MPa) at B metering position of screw structure diagram simultaneously, other conditions are identical with embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com