Carbon/carbon compositesyb 2 the si 2 o 7 Whisker toughened yb 2 sio 5 Preparation method of composite coating

A carbon composite material and composite coating technology, which is applied in the field of C/C composite materials, can solve the problems of long preparation period, difficult coating, difficult control of coating uniformity, etc., to achieve precise control of coating composition and avoid phase change and brittleness, simple and efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Carbon / carbon composite material Yb of the present invention 2 Si 2 o 7 Whisker toughened Yb 2 SiO 5 The preparation method of composite coating comprises the following steps:

[0034] 1) Choose the purity of commercially available iodine simple substance ≥ 99.7%, the purity of isopropanol ≥ 99.8%;

[0035] 2) Yb 2 Si 2 o 7 The preparation of whiskers comprises the following steps:

[0036] (1) Take Yb(NO) 3 ·5H 2 O, dissolved in absolute ethanol, prepared to a concentration of 0.5 ~ 1mol / L solution C; according to Yb(NO) 3 ·5H 2 O:Si(OC 2 h 5 ) 4 =1:(1~1.5) molar ratio, Si(OC 2 h 5 ) 4 Add it into solution A and stir well to obtain solution D; after drying solution D, obtain powder B, pre-calcine powder B at 200°C, and cool to room temperature to obtain powder C;

[0037] (2) Mix the powder C and the mixed double salt evenly according to the mass ratio of 1:(1~2), and then heat treat at 800~1000°C to obtain the powder D; wherein, the mixed double salt...

Embodiment 1

[0051] 1) Choose the purity of commercially available iodine simple substance ≥ 99.7%, the purity of isopropanol ≥ 99.8%;

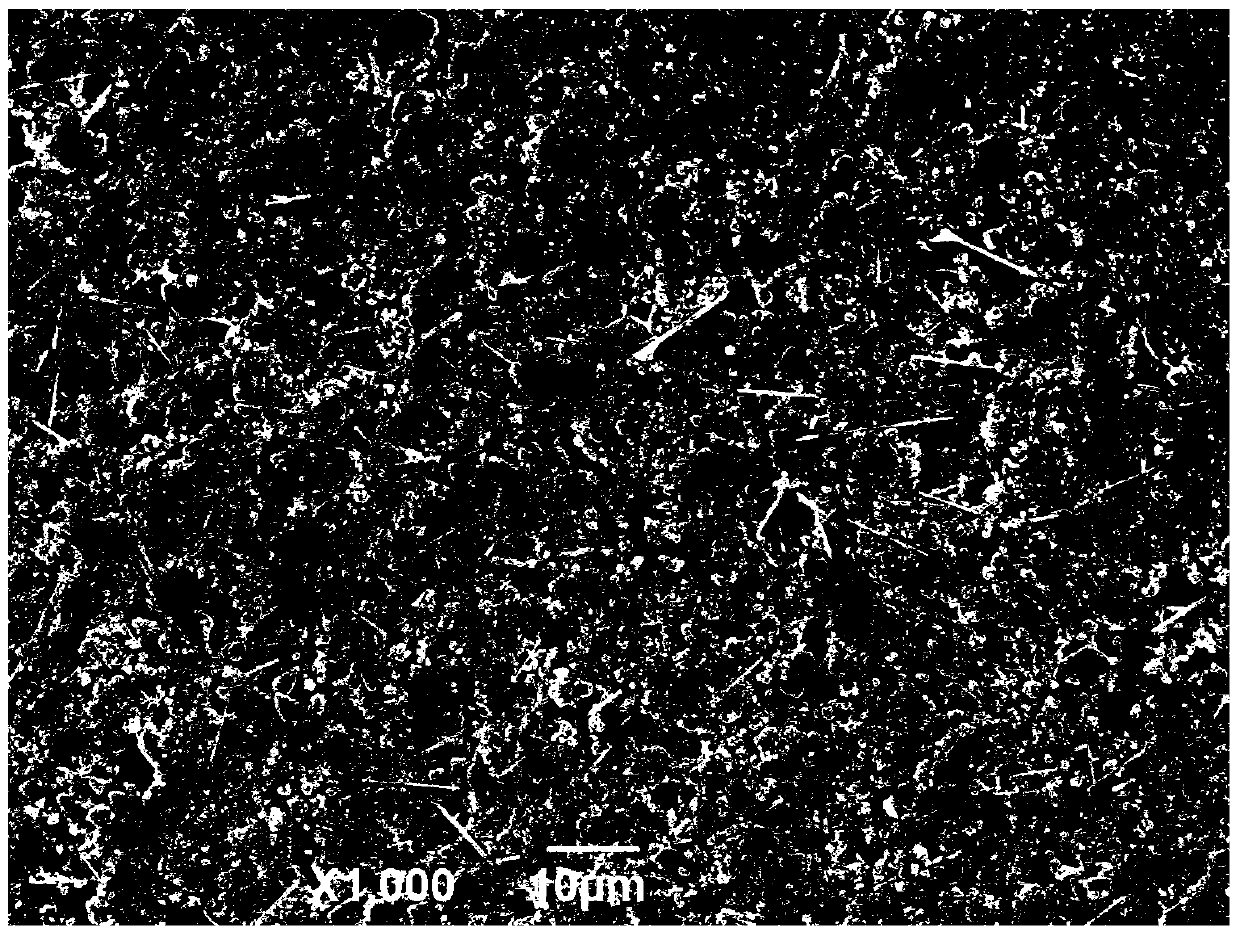

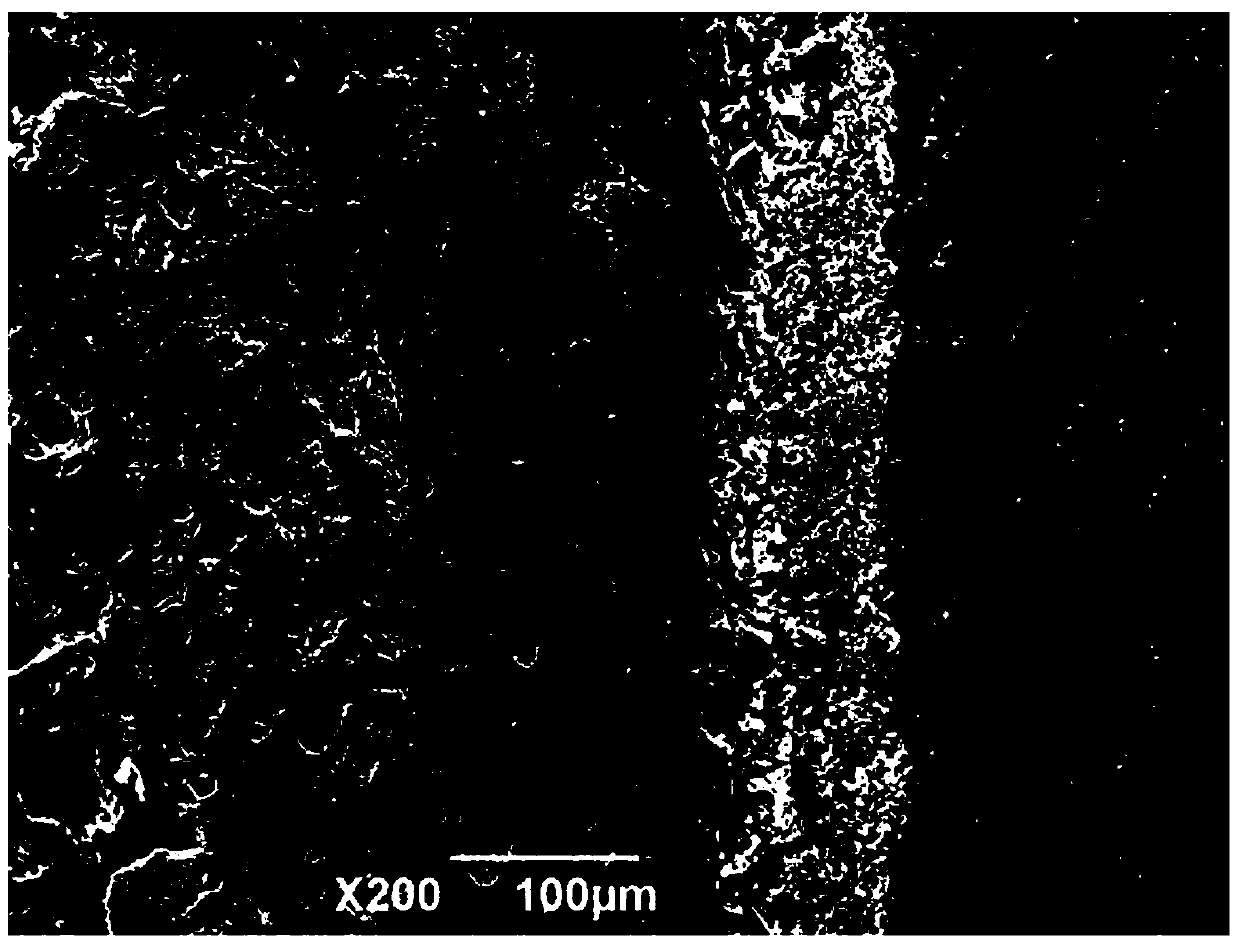

[0052] 2) Weigh an appropriate amount of Yb 2 SiO 5 Powder and Yb 2 Si 2 o 7 Whiskers (Yb 2 Si 2 o 7 The content of whiskers is 10% of the total mass of the two, Yb 2 SiO 5 The content of powder is 90% of the two total mass) dispersed in 1.5L isopropanol, is mixed with Yb 2 SiO 5 Powder and Yb 2 Si 2 o 7 For a suspension with a total concentration of whiskers of 30 g / L, the suspension was ultrasonically oscillated (ultrasonic power: 800 W) for 30 minutes, then placed on a magnetic stirrer and stirred for 3 hours to obtain suspension A;

[0053] 3) Add elemental iodine to suspension A (control the concentration of elemental iodine to be 4.0g / L) and then vibrate ultrasonically (ultrasonic power is 800W) for 40min, then place it on a magnetic stirrer and stir for 1h (heating and controlling during the stirring process) The heating temperature i...

Embodiment 2

[0059] 1) Choose the purity of commercially available iodine simple substance ≥ 99.7%, the purity of isopropanol ≥ 99.8%;

[0060] 2) Weigh an appropriate amount of Yb 2 SiO 5 Powder and Yb 2 Si 2 o 7 Whiskers (Yb 2 Si 2 o 7 The content of whiskers is 20% of the total mass of the two, Yb 2 SiO 5 The content of powder is 80% of both total mass) is dispersed in the 1.5L isopropanol, is mixed with Yb 2 SiO 5 Powder and Yb 2 Si 2 o 7 For a suspension with a total whisker concentration of 35 g / L, the suspension was ultrasonically oscillated (ultrasonic power: 800 W) for 40 minutes, then placed on a magnetic stirrer and stirred for 4 hours to obtain suspension A;

[0061] 3) Add elemental iodine to the suspension A (control the concentration of elemental iodine to be 4.2g / L) and then vibrate ultrasonically (ultrasonic power is 800W) for 30min, then place it on a magnetic stirrer and stir for 1h (heating and controlling during the stirring process) The heating temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com