A kind of preparation method of polyethersulfone based composite forward osmosis membrane

A technology of forward osmosis membrane and polyethersulfone, which is applied in the field of membrane separation, can solve the problems of internal concentration polarization, low permeation flux, and low porosity, and achieve reduced internal concentration polarization, high permeation flux and The effect of low retention rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

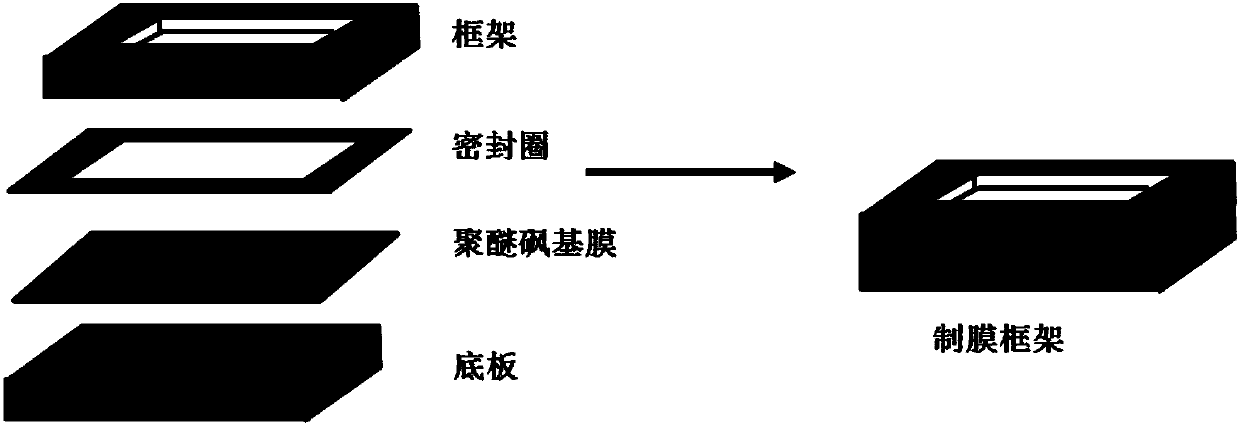

Method used

Image

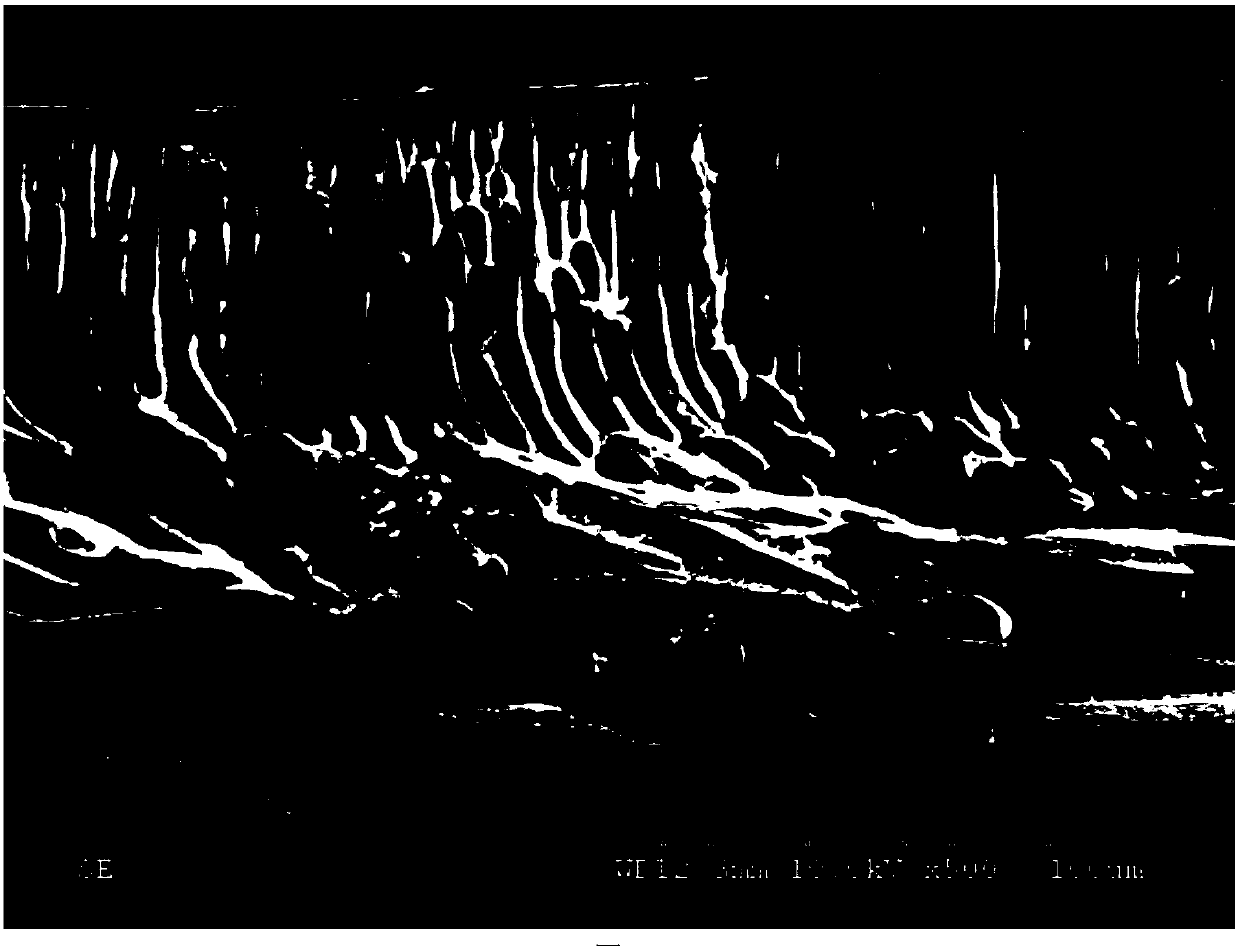

Examples

Embodiment 1

[0036] In the first step, dry polyethersulfone and additive polyethylene glycol in a vacuum oven at 50°C for 24 hours, add 17g polyethersulfone and 12g polyethylene glycol to 71g solvent, and the solvent is N,N-dimethyl A mixture of acetamide and diethylene glycol with a mass ratio of 1:1; then put the prepared mixture in an oil bath at 60°C and stir for 6 hours. When the solution is uniform and transparent, stop stirring and let it stand for 8 hours for defoaming. , to obtain the casting solution;

[0037] In the second step, evenly pour the casting solution on the top of the glass plate at 10°C, and then use a scraper to scrape a certain thickness of polymer solution from top to bottom;

[0038] In the third step, the glass plate is left to stand for 5 seconds to cause thermal phase separation (solid-liquid phase separation) of the casting solution;

[0039] The fourth step is to immerse the glass plate coated with the polymer solution in deionized water for 24 hours to ful...

Embodiment 2

[0044] Adjust the solid-liquid phase separation time in Step 3 in Example 1 to 10 s, and the remaining conditions are the same as in Example 1. The prepared composite forward osmosis membrane has a permeation flux of 31.6L / m 2 h, the reverse salt flux is 14.4g / m 2 h.

Embodiment 3

[0046]Adjust the mass of polyethersulfone in Step 1 in Example 1 to 18 g, and the rest of the conditions are the same as in Example 1. The prepared composite forward osmosis membrane has a permeation flux of 22.6L / m 2 h, the reverse salt flux is 12.0g / m 2 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com