GaN-based nanometer channel transistor with high electron mobility and manufacture method

A high electron mobility and nano-channel technology, applied in the field of microelectronic devices, can solve the problems of large leakage current, insufficient switching speed, and low transconductance, etc., and achieve small source-drain resistance, large saturation current, and gate control. The effect of good ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

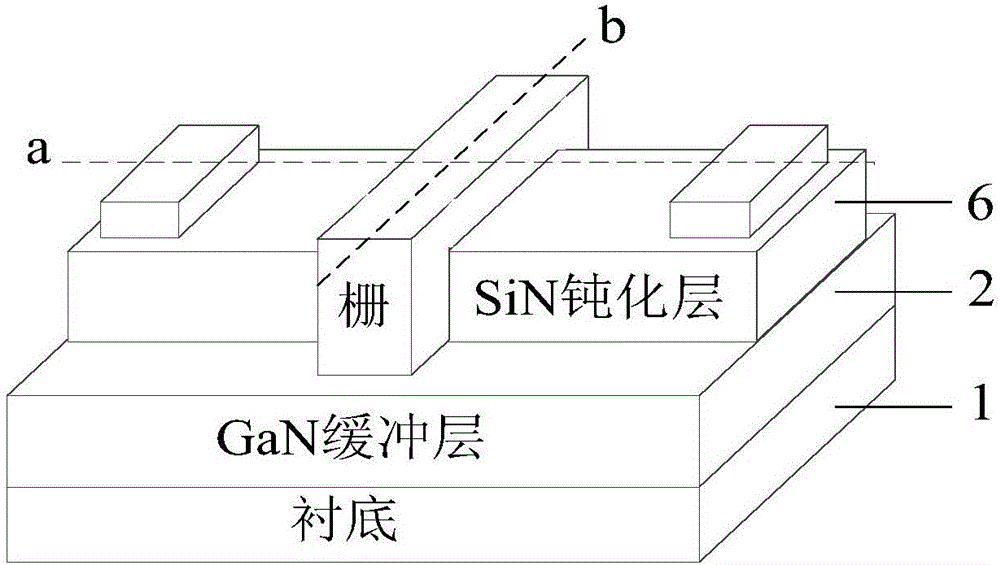

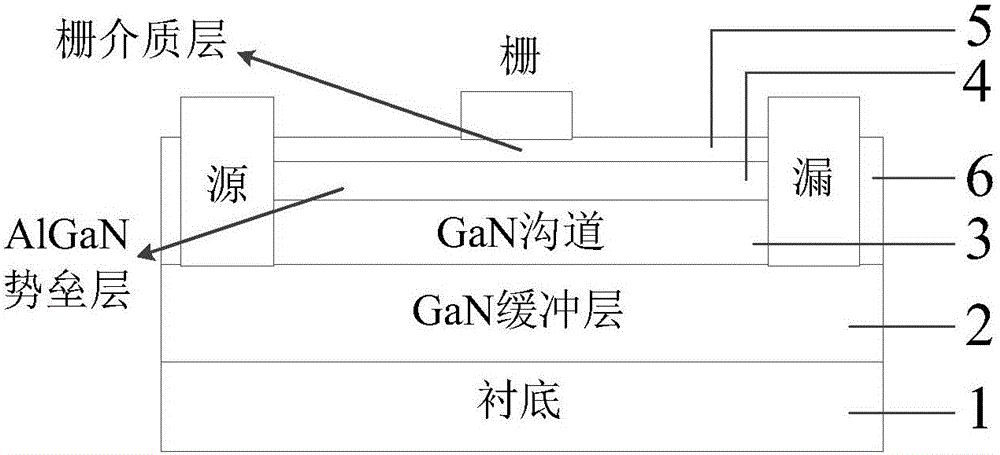

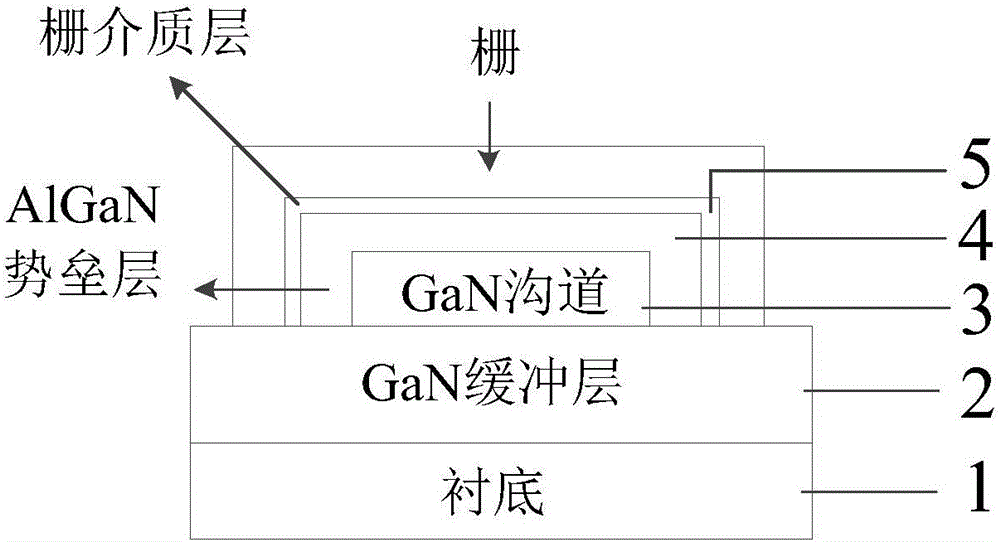

[0029] Embodiment 1: The production substrate is SiC, the thickness of the GaN buffer layer is 1 μm, the thickness of the GaN channel layer is 50 nm, the thickness of the AlGaN barrier layer is 15 nm, the Al composition is 30%, the thickness of the gate dielectric layer is 5 nm, and the passivation layer A high electron mobility device with a thickness of 50nm.

[0030] Step 1: A GaN buffer layer with a thickness of 1 μm is grown on the SiC substrate by metal-organic compound chemical vapor deposition MOCVD, and the process conditions are as follows:

[0031] The reaction gas is trimethylgallium and ammonia, the growth temperature is 800°C, and the pressure is 1.5×10 4 Pa.

[0032] Step 2: On the GaN buffer layer, a 50nm-thick GaN channel layer is grown on the GaN buffer layer by MOCVD, and the process conditions are as follows:

[0033] The reaction gas is trimethylgallium and ammonia, the growth temperature is 850°C, and the pressure is 1.5×10 4 Pa.

[0034] The growth r...

Embodiment 2

[0050] Embodiment 2: The production substrate is sapphire, the thickness of the GaN buffer layer is 1.2 μm, the thickness of the GaN channel layer is 70 nm, the thickness of the AlGaN barrier layer is 20 nm, the Al composition is 27%, the thickness of the gate dielectric layer is 7 nm, and the passivation Layer thickness is 75nm for high electron mobility devices.

[0051] Step 1: A GaN buffer layer with a thickness of 1.2 μm is grown on the sapphire substrate by metal-organic chemical vapor deposition MOCVD. The process conditions are: the reaction gas is trimethylgallium and ammonia, and the growth temperature is 800 ° C. The pressure is 1.5×10 4 Pa.

[0052] Step 2: On the GaN buffer layer, a 70nm-thick GaN channel layer is grown on the GaN buffer layer by MOCVD. The growth conditions are: the reaction gas is trimethylgallium and ammonia, and the growth temperature is 850°C The pressure is 1.5×10 4 Pa.

[0053] The growth results of the above steps 1 and 2 are as follow...

Embodiment 3

[0065] Embodiment 3: The production substrate is GaN, the thickness of the GaN buffer layer is 2 μm, the thickness of the GaN channel layer is 60 nm, the thickness of the AlGaN barrier layer is 20 nm, the Al composition is 22%, the thickness of the gate dielectric layer is 10 nm, and the passivation layer A high electron mobility device with a thickness of 100nm.

[0066] Step a: making a GaN buffer layer on the GaN substrate.

[0067] A layer of GaN buffer layer was grown on the GaN substrate by metal-organic compound chemical vapor deposition MOCVD. The growth process conditions were: the reaction gas was trimethylgallium and ammonia gas, the growth temperature was 800°C, and the pressure was 1.5×10 4 Pa, the thickness of the grown GaN buffer layer is 2 μm.

[0068] Step b: growing a GaN channel layer on the GaN buffer layer.

[0069] The GaN channel layer is grown on the GaN buffer layer by metal-organic compound chemical vapor deposition MOCVD. The growth process conditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com