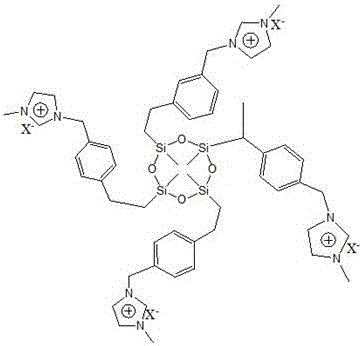

Tree-shaped framework ion liquid as well as preparation method and application of tree-shaped framework ion liquid

A technology of ionic liquids and skeletons, applied in the field of ionic liquids, can solve limitations and other problems, and achieve the effects of low viscosity, high yield, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: the preparation of catalyst

[0024] 1mol of chloroplatinic acid reacts with 7mol of octanol, and the ratio of the platinum atom to the chlorine atom is 1:2, and the complex coexists with octanal and octanyl ether, and the platinum in the complex exhibits +2 valence. 0.2gH 2 PtCl 6 ·6H 2 O and 2gC 8 h 17 Add OH to a 25mL single-necked flask, heat to 70~75°C under electromagnetic stirring, and depressurize at 3.3kPa for 12h to remove the formed water and hydrogen chloride to obtain a reddish-brown liquid product.

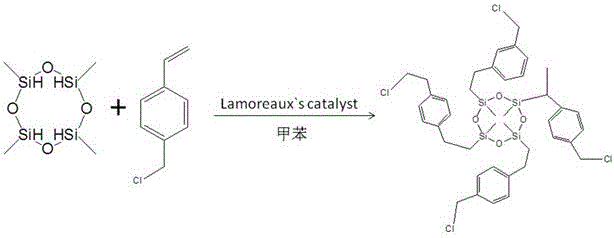

Embodiment 2

[0025] Embodiment 2: the preparation of the dendrimer skeleton of p-chloromethylstyrene siloxane hydrosilylation

[0026] Add 4.8g (0.02mol) 1,3,5,7-tetramethylcyclotetrasiloxane, 12.2g (0.08mol) p-chloromethylbenzene Ethylene and 20mL toluene, add 4 drops of Lamoreaux catalyst (2.48μmol "Pt", prepared in Example 1), heat to 80°C, react for 10h under nitrogen protection, monitor until p-chloromethylstyrene (developing agent is petroleum Ether: ethyl acetate 10:1) The reaction is complete. After cooling, 0.001 g of 2-mercaptobenzothiazole was added to deactivate the catalyst. The solvent was removed by rotary evaporation under reduced pressure to obtain a colorless viscous product. Among them, the ratio of β-addition product (reverse Markov addition) and α-addition product (Markov addition) is 3.5:1. As the temperature decreases, the ratio of Si-H / C=C decreases, and α-addition The proportion of products (Martensitic addition) increases. The yield was 48.6%. The reaction eq...

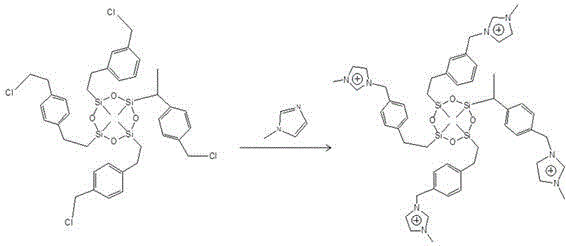

Embodiment 3

[0027] Embodiment 3: the preparation of dendrimer skeleton imidazolium ionic liquid cation

[0028] Add 2.0 g of 1-methylimidazole into a 100 ml four-neck flask equipped with a condenser, a thermometer, and electromagnetic stirring, heat to 80° C., slowly add 3.1 g of the product in Example 2 dropwise under nitrogen protection, and stop the reaction after 8 hours. The thick product was washed 5 times with 20 ml of ethyl acetate until no precipitation was precipitated after adding silver chloride, and the yellow transparent viscous product was obtained by rotary evaporation under reduced pressure. The yield was 68%. The reaction equation is as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com