3D printing repair method of chain wheel

A 3D printing and repair method technology, applied in the direction of process efficiency improvement, additive manufacturing, coating, etc., can solve problems such as waste, scrapping, and easy wear on the chain nest, so as to improve surface strength, reduce repair costs, and avoid The effect of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A 3D printing repair method for a sprocket, comprising the following steps:

[0027] (1) Scanning: Clean the surface defects, oxides, oil stains, etc. of the sprocket to be repaired, use a grinding wheel to polish off the surface fatigue layer until the metallic luster is exposed, and then perform a three-dimensional scan on the sprocket to obtain the surface of the sprocket Space coordinates, three-dimensional scanning technology can realize non-contact measurement, and has the advantages of fast speed and high precision;

[0028] (2) Model processing and code generation: the spatial coordinates of the sprocket surface are compared with the standard sprocket surface spatial coordinates to obtain a three-dimensional model that needs to be repaired, and then the three-dimensional model is sliced to generate numerical control codes;

[0029] (3) 3D printing: first use the laser red light to align the points to determine the origin of the part to be repaired; then run th...

Embodiment 2

[0034] The same parts as those in Example 1 will not be described again. The difference is that the composition and mass percentage of the alloy powder for the primer layer are: Cr16, Mn0.4, Si0.5, Ni23 and Mo2, and the balance is Fe. The alloy powder composition and mass percentage of the cover layer are: C0.8, Cr3, Mn0.3, Si0.2, Ni8, Mo3.0, V1.0 and W5.0, and the balance is Fe.

Embodiment 3

[0036] The same part as in Example 1 will not be described again, the difference is that the alloy powder composition and mass percentage of the bottom layer are: Cr20.4, Mn0.82, Si0.71, Ni26.5 and Mo3.3 , the balance being Fe. The alloy powder composition and mass percentage of the cover layer are: C1.0, Cr4, Mn0.7, Si0.4, Ni9, Mo4.0, V1.5 and W5.5, and the balance is Fe.

[0037] Carry out microstructure test and hardness test to the repaired sprocket sample obtained in this embodiment:

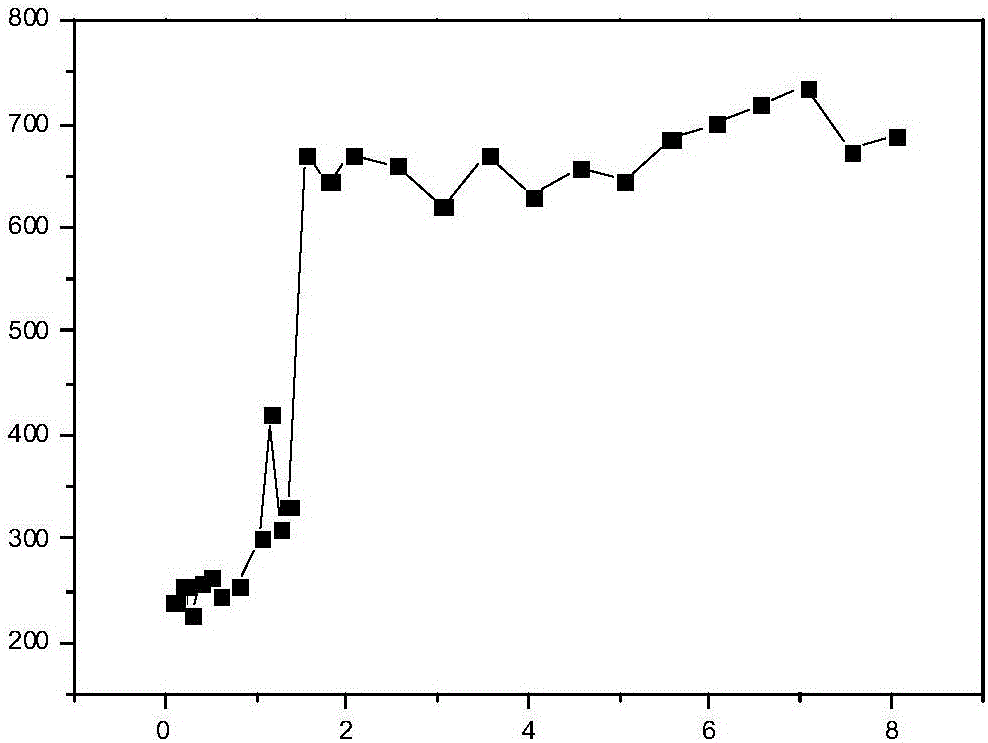

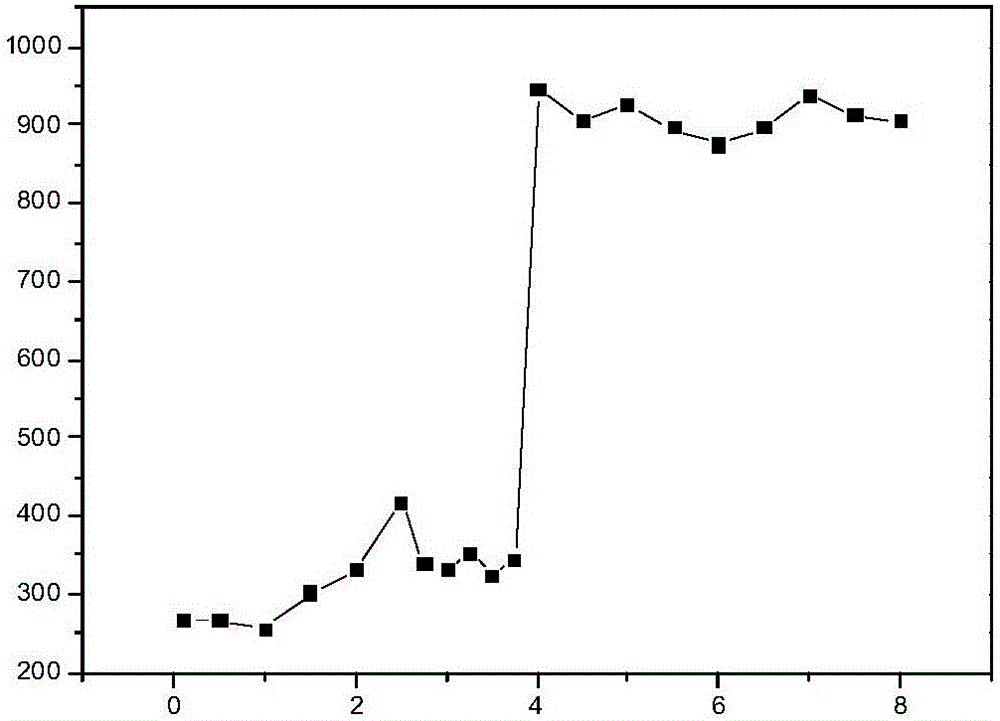

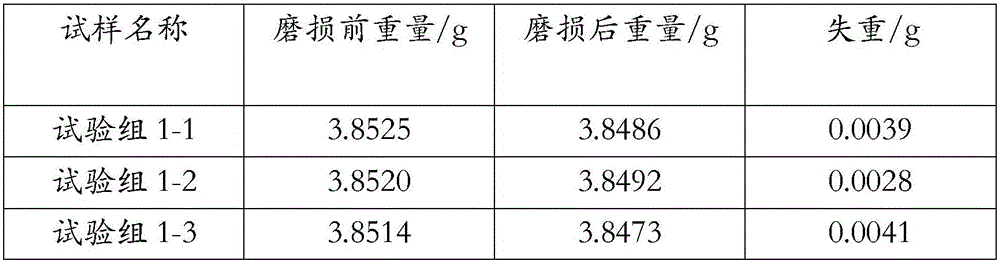

[0038] The size of the sample is 10×10×10mm. After being sanded and polished, use the HVS-1000A digital microhardness tester to test the hardness of the sample section. Floor. In order to facilitate observation, points are taken at intervals of 0.1mm in small areas, and intervals of stable hardness values are 0.5mm. Hardness results such as figure 1As shown, the abscissa is the distance from the surface of the substrate (in mm), and the ordinate is the hardness test result. The averag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Matrix hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com