System and method of preparing hydrogen rich gas and carbon monoxide from synthesis gas

A carbon monoxide and hydrogen-rich technology, which is applied in refrigeration and liquefaction, liquefaction, lighting and heating equipment, etc., can solve the problems of inability to obtain high purity, complicated process, high energy consumption, etc., meet the requirements of reducing impurities, increase H2 concentration, methane The effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

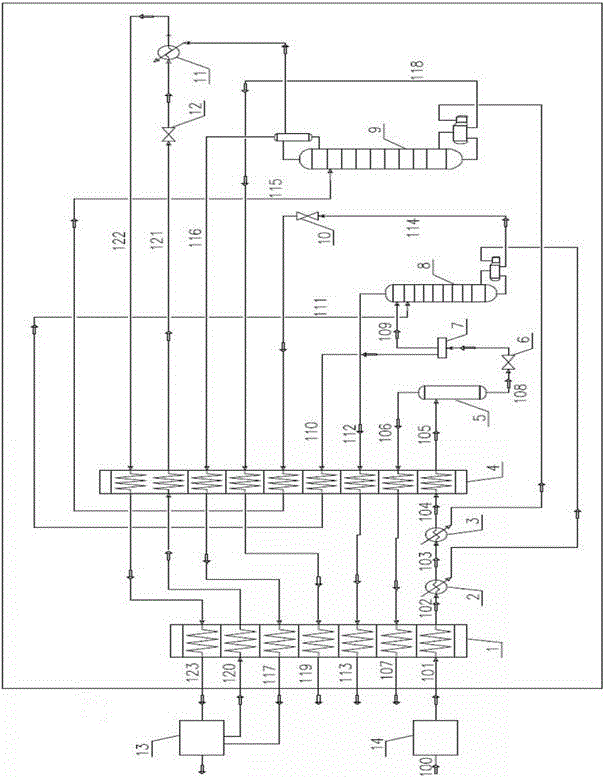

[0021] likefigure 1 As shown, a system for producing hydrogen-rich gas and carbon monoxide from synthesis gas mainly includes a synthesis gas purification unit 14, a low-temperature liquefaction separation unit, and a CO product compressor 13. The low-temperature liquefaction separation unit includes a first plate-fin Type heat exchanger 1, the second plate-fin heat exchanger 4, flash separator 5, high-pressure rectification tower 8, low-pressure rectification tower 9, the first evaporator 2 is set at the bottom of the high-pressure rectification tower, so A second evaporator 3 is provided at the bottom of the low-pressure rectification tower, and a first condenser 11 is provided at the top of the tower. The inlet of the purification unit is connected to the first pipeline 100 of raw material synthesis gas, and the outlet of the purification unit passes through the second The pipe 101 is connected to the first plate-fin heat exchanger, the inlet of the first evaporator is conne...

Embodiment 2

[0027] A method for producing hydrogen-rich gas and carbon monoxide from synthesis gas. The synthesis gas with a volume fraction of methane content of 0.5%~10% has a pressure of 3.0MPa~6.0MPa and passes through a purification unit. After being adsorbed by an adsorbent in the purification unit, the synthesis Trace CO in the air 2 and water removal, the synthetic gas after removal of impurities enters the first plate-fin heat exchanger through the second pipeline and is cooled to 145K~165K, and enters the first evaporator of the high-pressure rectification tower as a heat source to be further cooled to 128K ~135K, after cooling, enter the second evaporator of the low-pressure rectification tower through the fourth pipeline as a heat source and continue to cool to 103K~115K, after cooling again, enter the second plate-fin heat exchanger through the fifth pipeline to cool to 91K~95K, the cooled gas enters the flash separator through the sixth pipeline for flash separation. After p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com