Chinese astilbe herb ultra-fine powder decoction pieces and preparation method thereof

A technology of ultra-fine powder and ultra-fine powder for women is applied in powder delivery, pharmaceutical formulations, medical preparations containing active ingredients, etc., and can solve the problems of inconvenience in taking, low transfer rate of active ingredients, and easy destruction of active ingredients when heated. To achieve the effect of improving labor pain, improving bioavailability and reducing drug use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

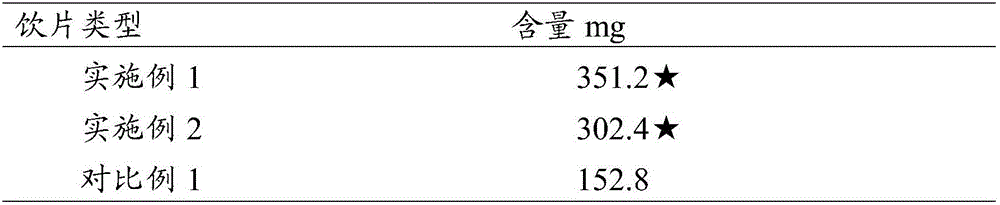

Examples

preparation example Construction

[0032] The invention provides a preparation method of astilbeia superfine powder decoction pieces, comprising the following steps:

[0033] 1) Pulverizing and sieving the Astilbee decoction pieces to obtain the above-sieve component and the under-sieve component;

[0034] 2) Superfinely pulverizing the under-sieve component obtained in the step 1) to obtain superfine powder of astilbee, the particle diameter of the superfine powder of astilbee ≤ 75 μm;

[0035] 3) mixing the superfine powder of astilbee obtained in the step 2) with auxiliary materials to obtain decoction pieces of superfine powder of astilbee.

[0036] The present invention adopts the technical solution for preparing astilbee superfine powder described in the above technical solution to prepare astilaginum superfine powder, which will not be repeated here.

[0037] After the superfine astilbe powder is obtained, the present invention mixes the superfine astilbe powder with auxiliary materials to obtain decoct...

Embodiment 1

[0050] First remove the silt, impurities, and non-medicinal parts of astilbee medicinal materials to obtain astilbee roots and rhizomes; then cut the washed astilbee roots and rhizomes into 3mm thick slices to obtain astilbee decoction pieces , using a continuous feeding pulverizer to pulverize Astilbee decoction pieces for 5 minutes, screen with 24 meshes, and pulverize the under-sieve components that can pass through the sieve holes with an ultrafine pulverizer, using airflow pulverization, the grinding pressure is 0.8Mpa, and the speed of the classifying wheel is 0.8Mpa. 5500rpm, the pulverization time is 3h, and pulverized into a powder with a particle size of ≤75 μm to obtain astilbe superfine powder;

[0051] Astilbee superfine powder is mixed with dextrin and starch in a mass ratio of 1:10:10 to obtain wet material;

[0052] Put the obtained wet material into the drying tray of the oven to dry, the thickness of the wet material in each baking tray is 2cm, the oven tempe...

Embodiment 2

[0054] First remove the silt, impurities, and non-medicinal parts of astilbee medicinal materials to obtain astilbee roots and rhizomes; then cut the washed astilbee roots and rhizomes into 3mm thick slices to obtain astilbee decoction pieces , using a continuous feeding pulverizer to pulverize Astilbee decoction pieces for 5 minutes, screen with 24 meshes, pulverize the sub-screen components that can pass through the sieve holes with a superfine pulverizer, and pulverize with a ball mill. The ball-to-material ratio is 10:1. The diameter is 0.5cm, the crushing time is 15h, and the rotating speed is 400rpm, and it is crushed into a powder with a particle size of ≤75 μm to obtain superfine powder of astilbe; all the components on the sieve that cannot pass through a 24-mesh sieve are mixed with 7 times the amount of 55% ethanol Extract the aqueous solution for 3 times to obtain the extract, use a rotary evaporator to concentrate the obtained extract at -0.1MPa, 55°C under reduced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com