Arranging method for loading nanometer titanium dioxide on textiles

A technology of nano-titanium dioxide and textiles, applied in textiles and papermaking, fiber treatment, fiber types, etc., can solve the problems of low utilization rate of TiO2, high energy consumption, weak combination, etc., achieve excellent anti-ultraviolet performance, simple finishing method, Good photocatalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

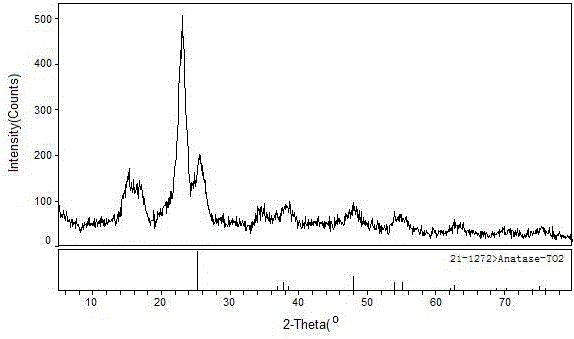

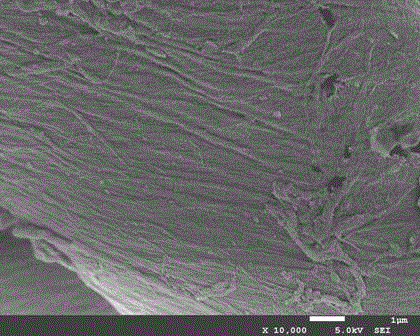

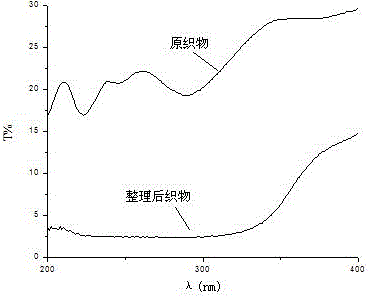

[0024] Clean the cotton fabric and dry it naturally in a ventilated place; take 8ml of butyl titanate and 8ml of absolute ethanol and mix evenly; take a 7cm×17cm fabric and dry it to remove the water molecules adsorbed on the surface of the cotton fabric, and then dry the cotton fabric Immerse in the aforementioned mixed solution for 30 seconds; take out the fabric and pass it through a paddle car, dipping and rolling, so that the liquid retention rate is about 95%, then hydrothermally treat the fabric in a water bath at 55°C for 2 hours (bath ratio is 1:30), take out the fabric in Dry at room temperature, wash with water, and dry in an oven at 100°C.

Embodiment 2

[0026] Clean the cotton fabric and dry it naturally in a ventilated place; take 10ml of butyl titanate and 4ml of absolute ethanol and mix evenly; take a 7cm×17cm fabric and dry it to remove the water molecules adsorbed on the surface of the cotton fabric, and then dry the cotton fabric Immerse in the above-mentioned mixed solution for 30 seconds; take out the fabric and pass it through a paddle car, dipping once and rolling twice, so that the liquid retention rate is about 85%. Dry at room temperature, wash with water, and dry in an oven at 100°C.

Embodiment 3

[0028] Clean the polyester fabric and dry it naturally in a ventilated place; take 10ml of butyl titanate and 5ml of absolute ethanol and mix evenly; take a 7cm×17cm fabric and dry it to remove the water molecules adsorbed on the surface of the cotton fabric, and then dry the cotton fabric Immerse in the above-mentioned mixed solution for 30 seconds; take out the fabric and pass it through a rolling machine, dipping and rolling, so that the liquid retention rate is about 70%, then hydrothermally treat the fabric in a water bath at 125°C for 1 hour (bath ratio is 1:30), take out the fabric in Dry at room temperature, wash with water, and dry in an oven at 120°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com