Tung oil polyol based anionic polyurethane with post-crosslinking capacity and preparation method of anionic polyurethane

A tung oil polyol and anion technology is applied in the field of polymer materials to achieve the effects of being beneficial to industrial production and popularization and application, low reaction temperature, and improved thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

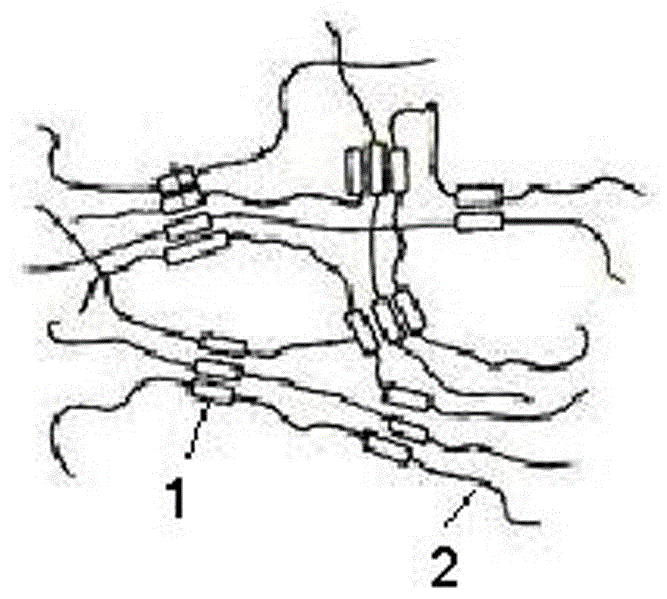

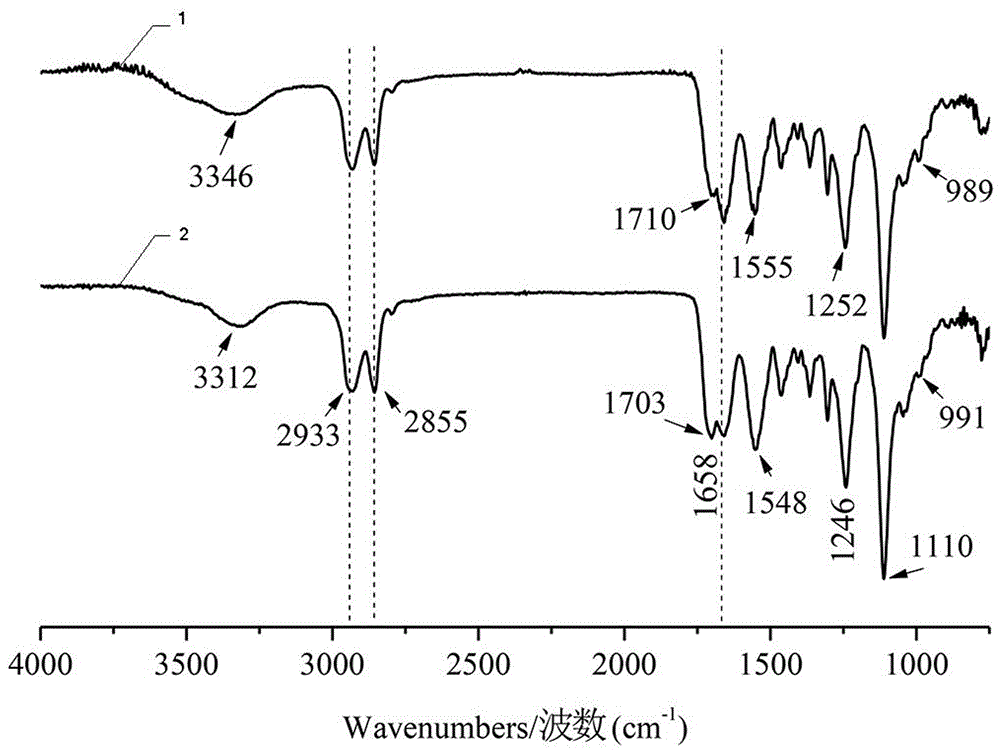

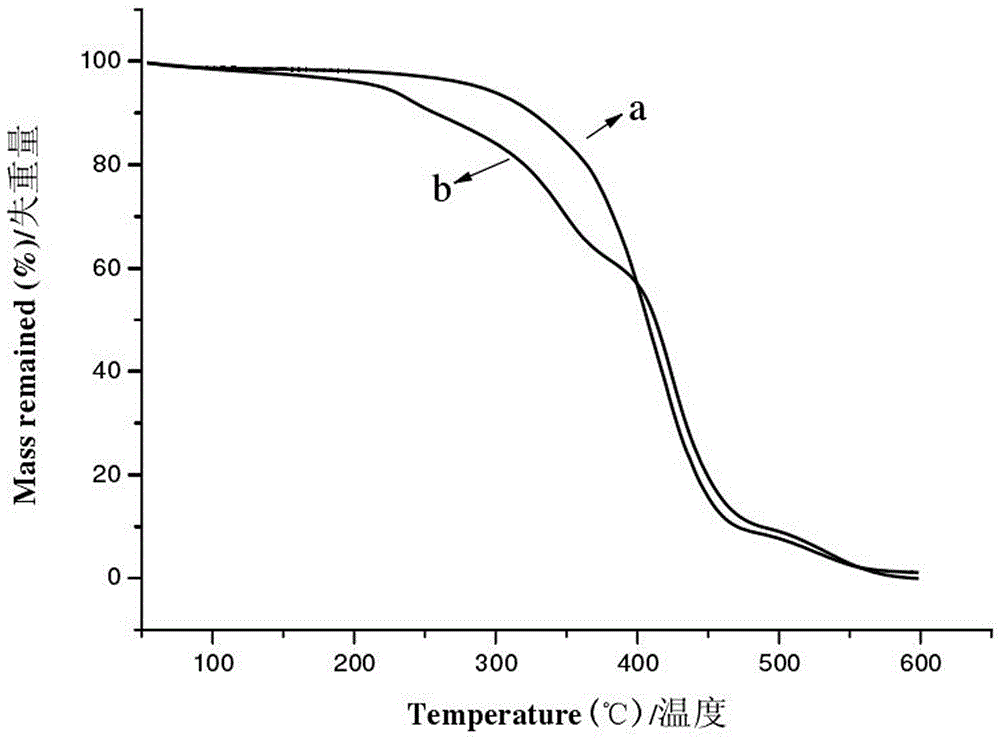

Image

Examples

Embodiment 1

[0034] After the reaction raw materials were fully dried, 19.2 g of isophorone diisocyanate (IPDI) and 13.2 g of hydroxylated tung oil were added to the four-necked bottle, and heated to 90° C. under nitrogen protection and stirring. When the NCO reached the theoretical value, Lower the temperature and add 35.89 g of polytetrahydrofuran diol (PTMG-2000) with a molecular weight of 2000 after drying and dewatering to continue the temperature rise reaction.

[0035] After the reaction in the previous step was completed, 3.97g of dimethylolpropionic acid (DMPA) was added to dissolve and cool down, then 11.97g of IPDI was added, and the temperature was slowly raised to 90°C for 2.5h. When the NCO reaches the theoretical value, cool the product with adjusted viscosity, add 2.99g of triethylamine, and after 20 minutes of neutralization, add distilled water and 2.96g of ethylenediamine, stir and mix at a high speed, so that the solid content of 30% can be obtained. Hydroxylated tung o...

Embodiment 2

[0036] Embodiment two: improve hydroxylated tung oil content

[0037] After the reaction raw materials are fully dried, add 10.9g of isophorone diisocyanate (IPDI) and 10.2g of hydroxylated tung oil, and heat to 90°C under nitrogen protection and stirring. When the NCO reaches the theoretical value, cool down and add dry water The polytetrahydrofuran glycol (PTMG) 21.6g that molecular weight is 1800 continues heating up reaction.

[0038] After the reaction in the previous step was completed, 2.41 g of dimethylolpropionic acid (DMPA) was added to dissolve and cool down, then 8.97 g of IPDI was added, and the temperature was slowly raised to 90°C for 2.5 hours. When the NCO reaches the theoretical value, cool the product with adjusted viscosity, add 1.81 g of triethylamine, neutralize for 20 minutes, add distilled water and 1.44 g of ethylenediamine, stir and mix at a high speed.

Embodiment 3

[0039] Embodiment three: reduce hydroxylated tung oil content

[0040] After the reaction raw materials are fully dried, add 7.98g of isophorone diisocyanate (IPDI) and 2.78g of hydroxylated tung oil, and heat to 90°C under nitrogen protection and stirring. When the NCO reaches the theoretical value, cool down and add dry water The polytetrahydrofuran diol (PTMG-2000) 27.38g that molecular weight is 2000 continues heating up reaction.

[0041] After the reaction in the previous step was completed, 3.05g of dimethylolpropionic acid (DMPA) was added to dissolve and cool down, then 6.17g of IPDI was added, and the temperature was slowly raised to 90°C for 2.5h. When the NCO reaches the theoretical value, cool the product with adjusted viscosity, add 2.3g of triethylamine, neutralize it for 20 minutes, add distilled water and 3.65g of ethylenediamine, stir and mix at a high speed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com