A combined process coupling aerobic biochemical treatment, ozone catalytic oxidation and biological denitrogenation for acrylonitrile wastewater

An ozone catalytic oxidation, aerobic biochemical technology, applied in natural water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Nitrogen ratio imbalance and other problems, to achieve the effect of reducing chemical consumption, large amount of activated sludge, and reducing dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

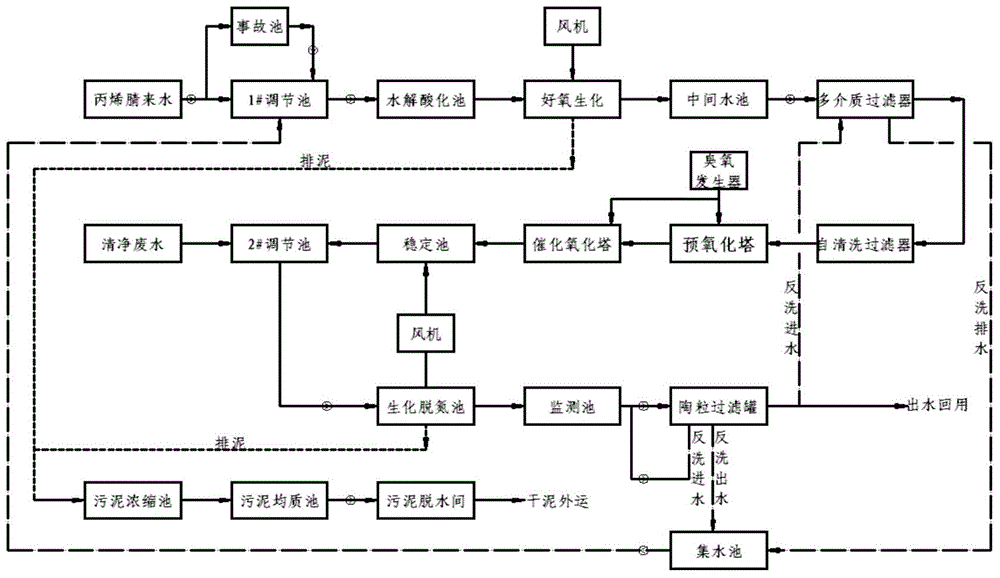

Method used

Image

Examples

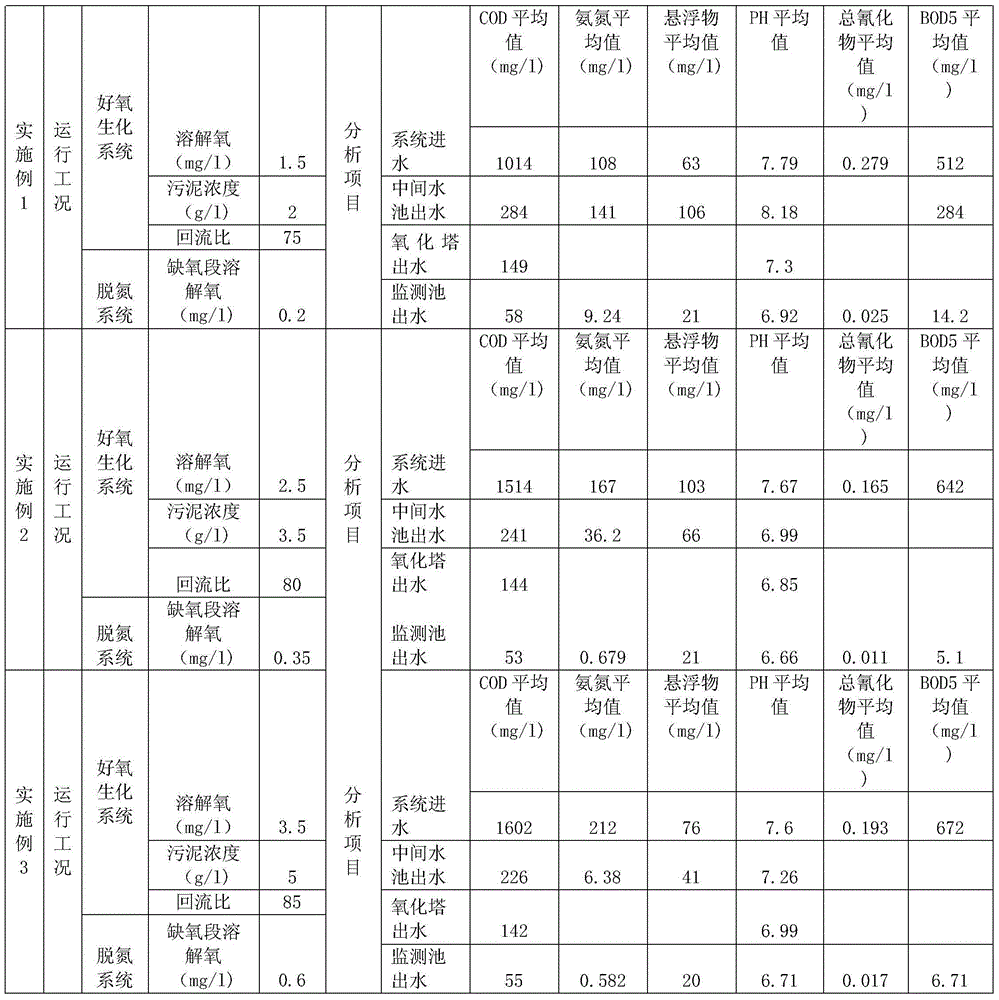

Embodiment 1

[0076] Example 1: Acrylonitrile incoming water (COD: 1014mg / l, ammonia nitrogen: 108mg / l) is upgraded to the aerobic biochemical system by the 1# regulating tank lifting pump. The aerobic biochemical system adopts low dissolved oxygen and high ratio of reflux. In the oxygen biochemical process, the dissolved oxygen is controlled at 1.5mg / l, the sludge concentration is controlled at 2g / l, the reflux ratio is controlled at 75%, and the aerobic biochemical system effluent (COD: 284mg / l, ammonia nitrogen: 141mg / l) flows to Intermediate pool, the effluent of the intermediate pool is pumped to the multi-media filter, the effluent of the multi-media filter flows to the ozone catalytic oxidation tower by itself, the effluent from the oxidation tower (COD: 149mg / l) flows to the stabilization pool by itself, and the effluent of the stabilization pool is pumped to denitrification In the denitrification tank, the dissolved oxygen in the anoxic section is controlled at 0.2mg / l, and the efflu...

Embodiment 2

[0077] Example 2: Acrylonitrile incoming water (COD: 1514mg / l, ammonia nitrogen: 167mg / l) is upgraded to the aerobic biochemical system by the 1# regulating tank lifting pump. The aerobic biochemical system adopts low dissolved oxygen and high ratio of reflux. Oxygen biochemical process, the dissolved oxygen is controlled at 2.5mg / l, the sludge concentration is controlled at 3.5g / l, the reflux ratio is controlled at 80%, and the aerobic biochemical system effluent (COD: 241mg / l, ammonia nitrogen: 36.2mg / l) The effluent from the intermediate pool is pumped to the multi-media filter. The effluent from the multi-media filter flows to the ozone catalytic oxidation tower. The effluent from the oxidation tower (COD: 144mg / l) flows to the stabilization pool. The effluent of the stabilization pool is raised to Denitrification tank, the oxygen in the anoxic section of the denitrification tank is controlled at 0.35mg / l, the effluent from the denitrification tank (COD: 53mg / l, ammonia nitr...

Embodiment 3

[0078] Example 3: Acrylonitrile incoming water (COD: 1602mg / l, ammonia nitrogen: 212mg / l) is upgraded to the aerobic biochemical system by the 1# regulating tank lifting pump. The aerobic biochemical system adopts low dissolved oxygen and high ratio of reflux. Oxygen biochemical process, the dissolved oxygen is controlled at 3.5mg / l, the sludge concentration is controlled at 5g / l, the reflux ratio is controlled at 85%, the aerobic biochemical system effluent (COD: 226mg / l, ammonia nitrogen: 6.38mg / l) is self-flowing To the intermediate pool, the effluent of the intermediate pool is lifted to the multi-media filter with a pump, the effluent from the multi-media filter flows to the ozone catalytic oxidation tower by itself, the effluent from the oxidation tower (COD: 142mg / l) flows to the stabilization pool, and the effluent from the stabilization pool is lifted to the dewatering Nitrogen tank and denitrification tank control the dissolved oxygen in the anoxic section at 0.6mg / l, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com