High-performance zirconium cerium titanium solid-solution catalyst for flue gas denitration and preparation method thereof

A solid solution, zirconium cerium titanium technology, applied in heterogeneous catalyst chemical elements, physical/chemical process catalysts, gas treatment, etc., can solve the problems of small specific surface area, poor mechanical strength, etc., and achieve high denitrification performance and thermal stability Good, good water and sulfur resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1. Zr 0.02 Ce 0.08 Ti 0.9 o 2 Preparation of solid solution catalyst

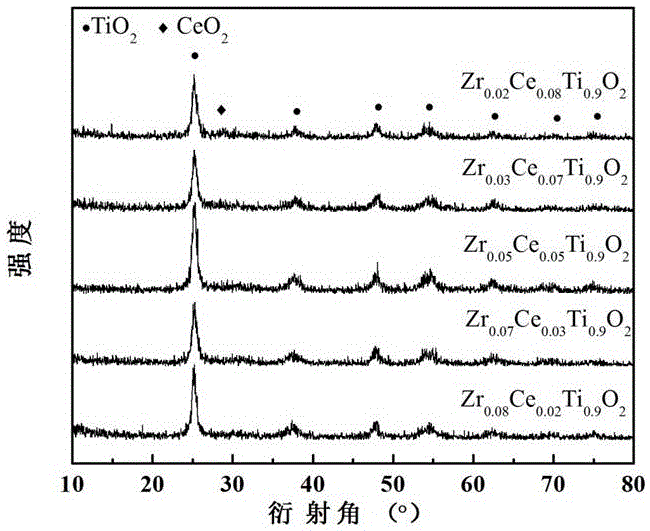

[0020] Dissolve 0.07g of zirconium nitrate, 0.36g of cerium nitrate and 3.62g of titanium sulfate in 200mL of distilled water, stir magnetically at room temperature for 30min to mix evenly, then add concentrated ammonia water drop by drop, adjust the pH value to 10, at 90 o Magnetic stirring in C water bath for 3h to make the precipitation complete, aging for 24h, suction filtration, washing, filter cake at 110 o C dried for 12h, ground evenly, in the air atmosphere in the muffle furnace at 550 o C is roasted for 5h to get Zr 0.02 Ce 0.08 Ti 0.9 o 2 solid solution catalyst. Its XRD measurement result sees figure 1 , H 2 -TPR results see figure 2 , the denitrification performance test results are shown in image 3 .

Embodiment 2

[0021] Example 2. Zr 0.03 Ce 0.07 Ti 0.9 o 2 Preparation of solid solution catalyst

[0022] Dissolve 0.11g of zirconium nitrate, 0.33g of cerium nitrate and 3.62g of titanium sulfate in 200mL of distilled water, stir magnetically at room temperature for 30min to mix evenly, then add concentrated ammonia water drop by drop, adjust the pH value to 10, at 90 o Magnetic stirring in C water bath for 3h to make the precipitation complete, aging for 24h, suction filtration, washing, filter cake at 110 o C dried for 12h, ground evenly, in the air atmosphere in the muffle furnace at 550 o C is roasted for 5h to get Zr 0.03 Ce 0.07 Ti 0.9 o 2 solid solution catalyst. Its XRD measurement result sees figure 1 , H 2 -TPR results see figure 2 , the denitrification performance test results are shown in image 3 , at 350 o The results of water and sulfur resistance of C are shown in Figure 4 .

Embodiment 3

[0023] Example 3. Zr 0.05 Ce 0.05 Ti 0.9 o 2 Preparation of solid solution catalyst

[0024] Dissolve 0.21g of zirconium nitrate, 0.22g of cerium nitrate and 3.62g of titanium sulfate in 200mL of distilled water, stir magnetically at room temperature for 30min to mix evenly, then add concentrated ammonia water drop by drop, adjust the pH value to 10, at 90 o Magnetic stirring in C water bath for 3h to make the precipitation complete, aging for 24h, suction filtration, washing, filter cake at 110 o C dried for 12h, ground evenly, in the air atmosphere in the muffle furnace at 550 o C is roasted for 5h to get Zr 0.05 Ce 0.05 Ti 0.9 o 2 solid solution catalyst. Its XRD measurement result sees figure 1 , H 2-TPR results see figure 2 , the denitrification performance test results are shown in image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com