Preparation and application of nitrogen, sulphur or chlorine-doped three-dimensional porous graphene catalyst

A three-dimensional porous and graphene technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of rare research reports on doped graphene, achieve the effect of overcoming corrosion problems, simple operation, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

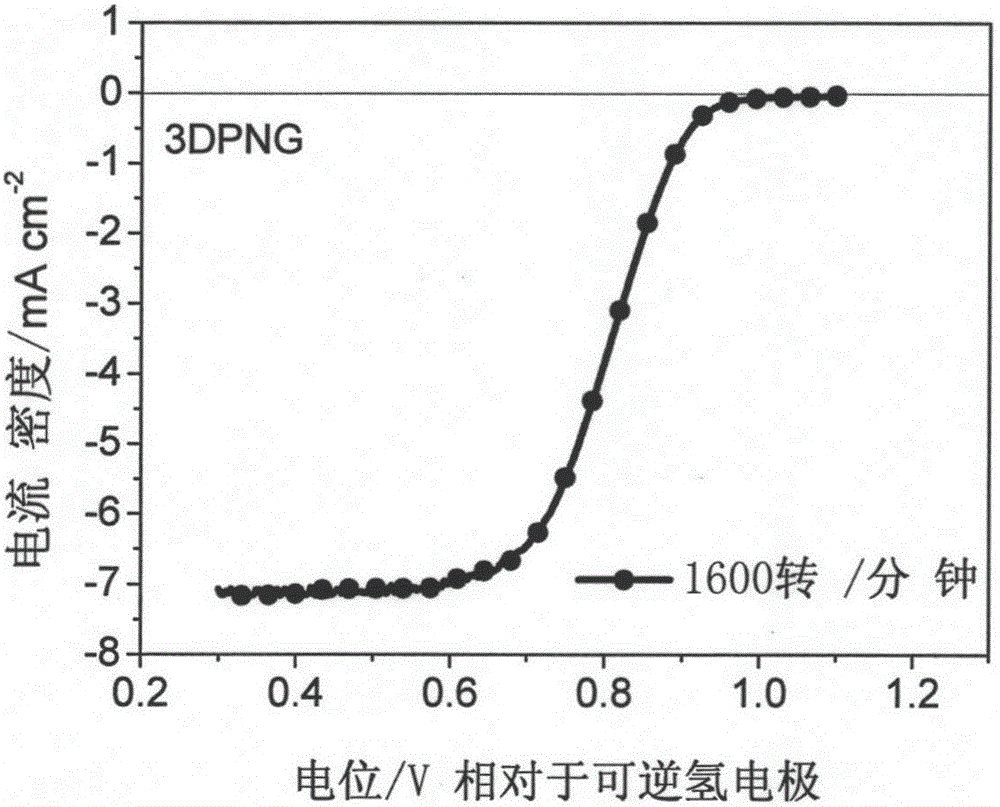

[0043] A preparation method of nitrogen-doped three-dimensional porous graphene catalyst, the specific steps are:

[0044] (1) Weigh 100 mg of graphene oxide and dissolve it in 100 mL of absolute ethanol, sonicate for 1 hour to obtain a uniform graphene oxide suspension, add 3 mL of 3-aminopropyltriethoxysilane dropwise while stirring slowly, and then Slowly add 0.5mL of hydrochloric acid with a concentration of 2M, then slowly add 10mL of anhydrous ethanol solution in which 400mg of ferrous chloride tetrahydrate is dissolved, and react the above mixed solution in a water bath for 6 hours (the temperature of the water bath is 60°C). Dry it in an oven at 85°C overnight, and grind it into powder to obtain a catalyst precursor.

[0045] (2) Place the above precursor in a quartz boat, under N 2 Under the protection of the atmosphere, the temperature was raised to 900°C at a rate of 5°C / min and the reduction treatment was carried out for 1 hour to obtain a primary carbonized produ...

Embodiment 2

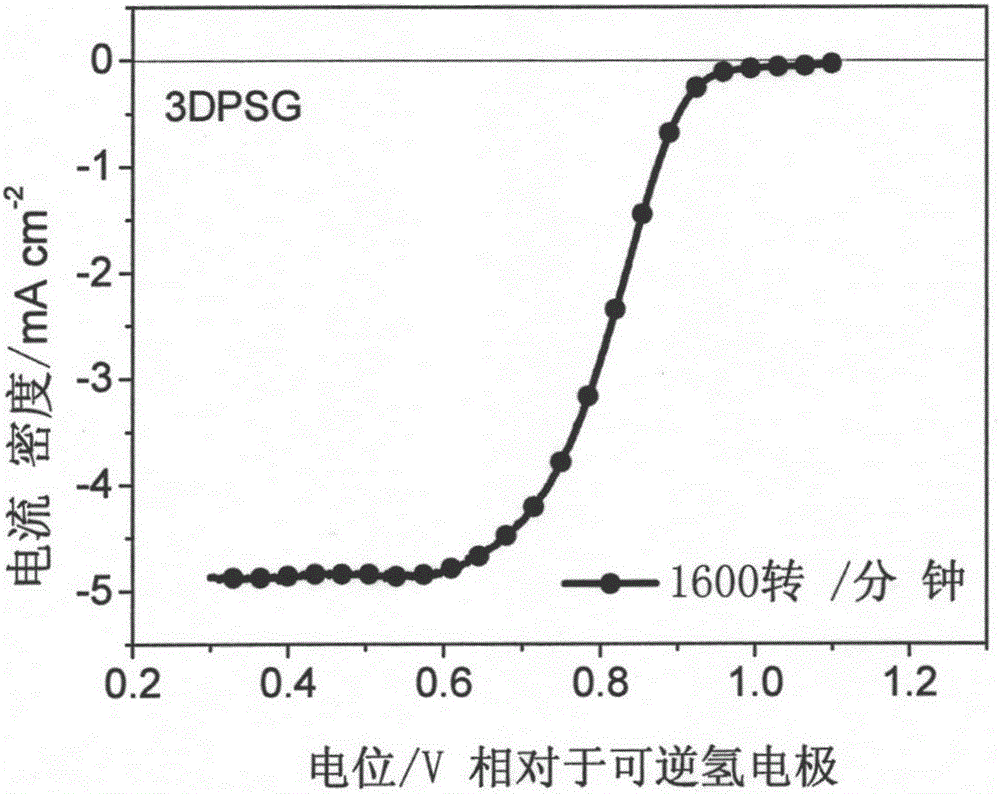

[0047] A preparation method of a sulfur-doped three-dimensional porous graphene catalyst, the specific steps are:

[0048] (1) Weigh 100mg of graphene oxide (GO) and dissolve it in 100mL of absolute ethanol, sonicate for 1 hour to obtain a uniform graphene oxide suspension, add 3mL of mercaptopropyltrimethoxysilane dropwise while stirring slowly, Then slowly add 0.5mL of hydrochloric acid with a concentration of 2M, and then slowly add 10mL of anhydrous ethanol solution dissolved with 400mg of ferrous chloride tetrahydrate, and react the above mixed solution in a water bath for 6 hours (the temperature of the water bath is 60°C). Dry it overnight in an oven at 85°C, and grind it into powder to obtain a catalyst precursor.

[0049] (2) Place the above precursor in a quartz boat, under N 2 Under the protection of the atmosphere, the temperature was raised to 900°C at a rate of 5°C / min and the reduction treatment was carried out for 1 hour to obtain a primary carbonized product....

Embodiment 3

[0051] A preparation method of chlorine-doped three-dimensional porous graphene catalyst, the specific steps are:

[0052] (1) Weigh 100mg of graphene oxide (GO) and dissolve it in 100mL of absolute ethanol, sonicate for 1 hour to obtain a uniform graphene oxide suspension, add 3mL of 3-chloropropyltrimethoxysilane dropwise while stirring slowly , then slowly drop 0.5mL of hydrochloric acid with a concentration of 2M, then slowly add 10mL of anhydrous ethanol solution that is dissolved with 400mg of ferrous chloride tetrahydrate, and react the above mixed solution in a water bath for 6 hours (the temperature of the water bath is 60°C) Afterwards, it was dried overnight in an oven at 85° C., and ground into powder to obtain a catalyst precursor.

[0053] (2) Place the above precursor in a quartz boat, under N 2 Under the protection of the atmosphere, the temperature was raised to 900°C at a rate of 5°C / min and the reduction treatment was carried out for 1 hour to obtain a prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com