Preparation method of polyacrylonitrile-based precursor

A polyacrylonitrile-based, precursor technology, applied in the preparation of spinning solution, single-component synthetic polymer rayon, wet spinning, etc. problems, to achieve the effect of maintaining stability, ensuring stability, and controlling wire breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

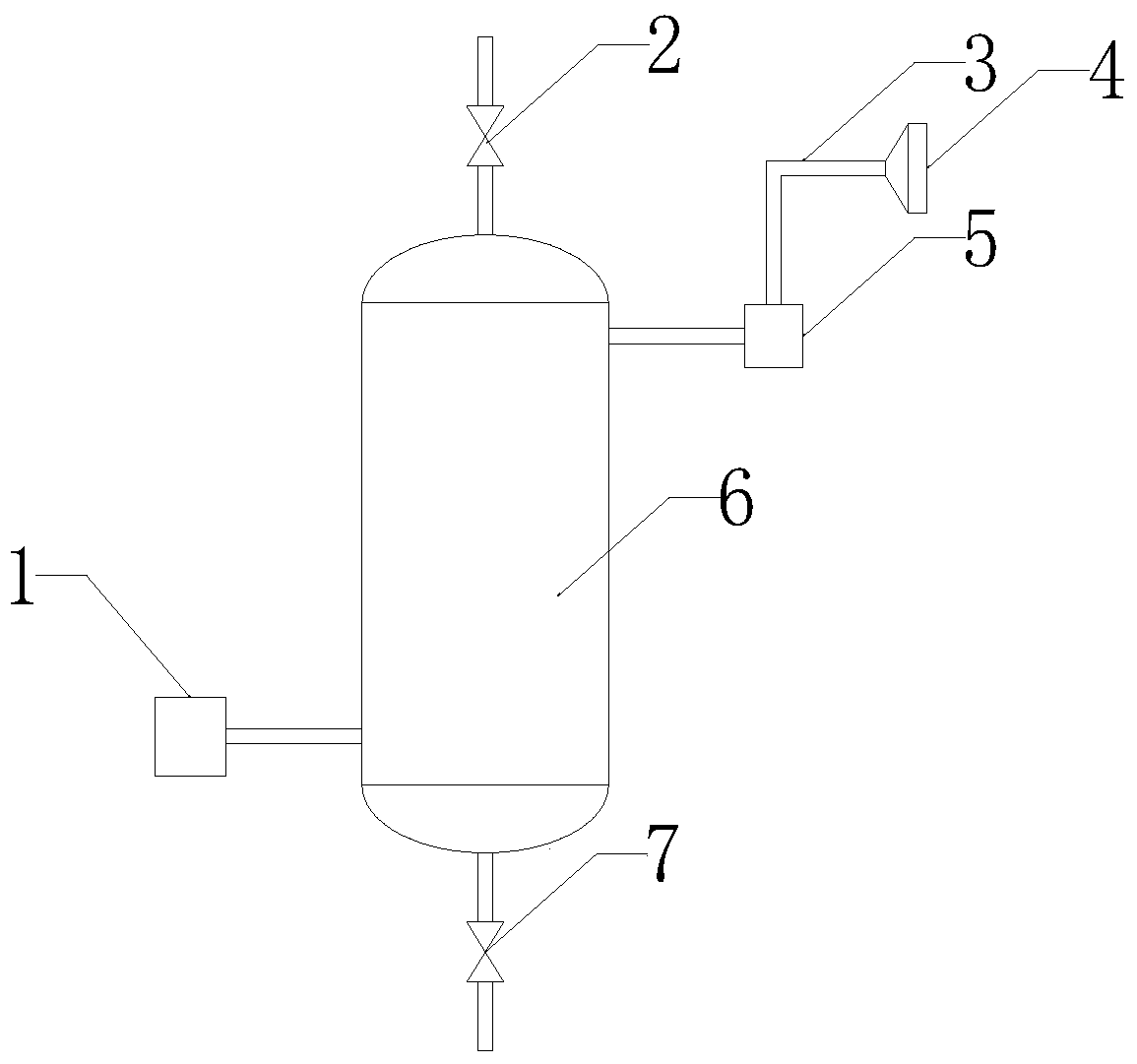

Image

Examples

Embodiment 1

[0018] 1. Preparation of stock solution: Distilled acrylonitrile (AN) and itaconic acid (IA) in a ratio of 97:3, with a solid content of 20%, and azobisisobutyronitrile (AIBN) accounts for 0.4wt% of the comonomer, Add dimethyl sulfoxide (DMSO) as a solvent into the reactor, and react at a constant temperature of 38° C. for 20 hours under the protection of nitrogen to obtain a binary acrylonitrile copolymer spinning solution. Then the spinning solution is decompressed to remove residual monomers and air bubbles, and then filtered through a 5 μm filter material. The filter assembly used first wets the filter, and the dimethyl sulfoxide solvent accounts for 40% of the volume of the filter. The temperature is controlled at 60°C, the vacuum degree of the filter vacuum is at -45KPa (gauge pressure), the speed of the metering pump is controlled so that the rising speed of the stock solution is 25mm / min, the discharge time of the bottom valve is controlled at 15min, and the discharge t...

Embodiment 2

[0026] 1. Preparation of stock solution: Distilled acrylonitrile (AN) and itaconic acid (IA) in a ratio of 97:3, with a solid content of 20%, and azobisisobutyronitrile (AIBN) accounts for 0.4wt% of the comonomer, Add dimethyl sulfoxide (DMSO) as a solvent into the reactor, and react at a constant temperature of 38° C. for 20 hours under the protection of nitrogen to obtain a binary acrylonitrile copolymer spinning solution. Then the spinning solution is decompressed to remove residual monomers and air bubbles, and then filtered through a 5 μm filter material. The filter assembly used first wets the filter, and the dimethyl sulfoxide solvent accounts for 40% of the volume of the filter. The temperature is controlled at 60°C, the vacuum degree of the filter is evacuated at -45KPa (gauge pressure), the speed of the metering pump is controlled so that the rising speed of the stock solution is 30mm / min, the discharge time of the bottom valve is controlled at 20min, and the discharg...

Embodiment 3

[0029] 1.1. Preparation of stock solution: Distilled acrylonitrile (AN) and itaconic acid (IA) in a ratio of 97:3, with a solid content of 20%, and azobisisobutyronitrile (AIBN) accounts for 0.4wt of the comonomer %, put dimethyl sulfoxide (DMSO) into the reactor as a solvent, and react at a constant temperature of 38° C. for 20 hours under the protection of nitrogen to obtain a binary acrylonitrile copolymer spinning solution. Then the spinning solution is decompressed to remove residual monomers and air bubbles, and then filtered through a 5 μm filter material. The filter assembly used first wets the filter, and the dimethyl sulfoxide solvent accounts for 40% of the volume of the filter. The temperature is controlled at 60°C, the vacuum degree of the filter vacuum is at -45KPa (gauge pressure), the speed of the metering pump is controlled so that the rising speed of the stock solution is 22mm / min, the discharge time of the bottom valve is controlled at 12min, and the discharge ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com