A method for preparing high-purity manganese-bismuth (MNBI) alloy

A pure manganese-bismuth alloy technology, applied in the field of magnetic functional materials, can solve the problems of restricting the application of MnBi alloy materials, difficulty in synthesis of MnBi alloy materials, low magnetic properties of alloy materials, etc., and achieve high melting point, improved purity, and high thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of high-purity MnBi alloy comprises the following steps:

[0020] 1. Select Bi and Mn powders as raw materials, and the Bi and Mn are 99%-99.999% nano or micron powders.

[0021] ②. Proportion the Bi and Mn powders selected in the above ① according to the molar ratio 1:x (x=1.0-2.0), mix them uniformly and package them in molybdenum cups, and carry out low-pressure pretreatment on the molybdenum cup samples through a powder molding press. Treatment or ultra-high pressure pretreatment of molybdenum cup samples by domestic six-sided top hydraulic press, the pressure range of low pressure pretreatment is 2-40MPa, and the pressure range of high pressure pretreatment is 1-6 GPa.

[0022] ③. Put the molybdenum cup cavity pre-pressed in ② into the crucible, and complete the preparation of MnBi alloy through closed low-temperature sintering and quenching procedures, and prepare high-purity MnBi alloy (95 at.%). Closed low-temperature sintering is to synt...

Embodiment 1

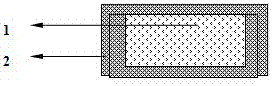

[0024] as attached figure 1 Shown: Select 3.0g of Bi and Mn mixed powder (average particle size 3-5 μm, molar ratio 1:1) as raw material, such as figure 1 Shown in number 1. Put the mixed powder into the molybdenum cup cavity of outer cup Φ13.65×5 mm and inner cup Φ13.38×5 mm, such as figure 1 Shown in number 2. The low-pressure pre-compression sealing treatment was carried out on the powder molding press, and the pressure condition was 2 MPa to obtain a dense Bi-Mn sample block sealed by a Φ 14×3.2 mm molybdenum cup.

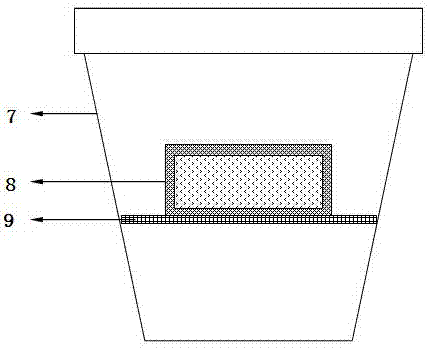

[0025] as attached image 3 Shown: Put the sealed molybdenum cup sample block into a ceramic crucible with a volume of about 40ml, such as image 3 Shown in number 7. Place the molybdenum cup closed cavity (after pre-pressing) 8 and the large-aperture metal mesh 9 from top to bottom, and perform low-temperature heat treatment in a muffle furnace with a sintering temperature of 270 °C and a holding time of 50 h. After cooling, a Φ 13.5×3 mm high-purity MnB...

Embodiment 2

[0027] as attached figure 1 Shown: Select 3.0g of Bi and Mn mixed powder (average particle size 3-5 μm, molar ratio 1:1.3) as raw material, such as figure 1 Shown in number 1. Put the mixed powder into the molybdenum cup cavity of the outer cup Φ13.65×5 mm and the inner cup Φ13.38×5mm, such as figure 1 Shown in number 2. The low-pressure pre-compression sealing treatment was carried out on the powder molding press, and the pressure condition was 15 MPa to obtain a dense Bi-Mn sample block sealed by a Φ 14×3.2 mm molybdenum cup.

[0028] as attached image 3 Shown: Put the sealed molybdenum cup sample block into a ceramic crucible with a volume of about 40ml, such as image 3 Shown in number 7. According to the sequence of molybdenum cup closed cavity (after pre-pressing) 8 and large-aperture metal mesh 9 from top to bottom, low-temperature heat treatment is carried out in the muffle furnace, the sintering temperature is 280 °C, the holding time is 20 h, quenching After c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com