Nano-material and preparation method and application thereof

A nanomaterial, nanotechnology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high energy consumption, solute time difference, long time consumption, etc., to achieve low energy consumption, Short time and process controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] a. Gear-shaped nano-WO 3 Precursor preparation:

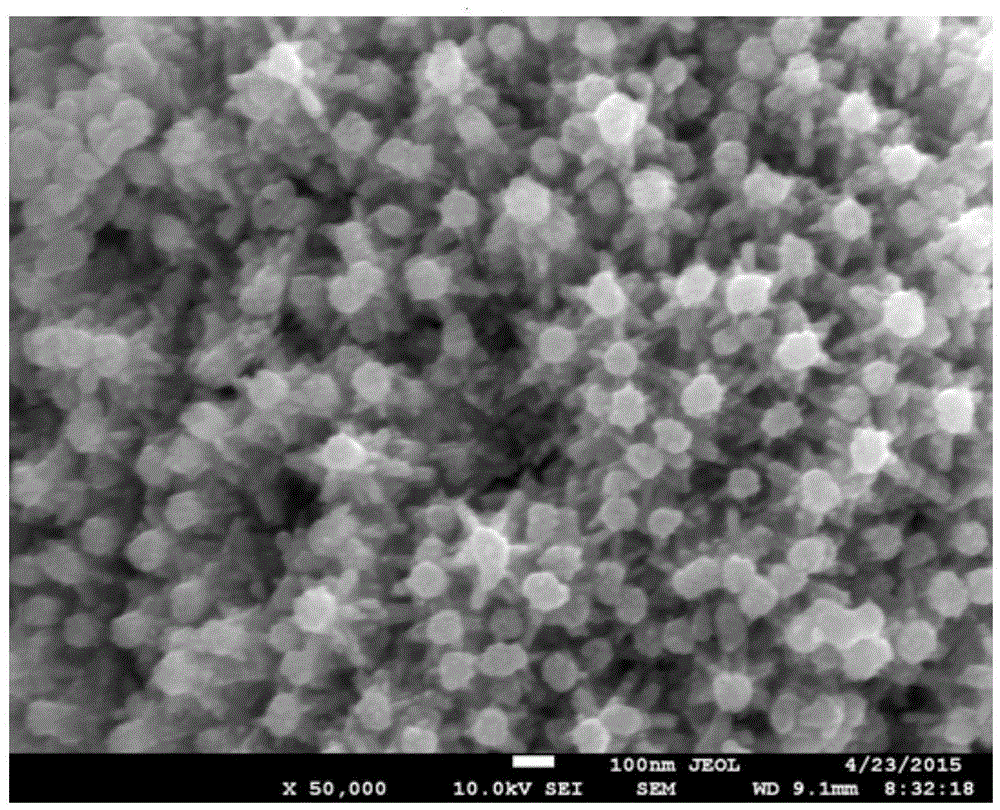

[0030] Use a small container to measure a certain amount of ethylene glycol, and accurately weigh a certain amount of WCl 6 Dissolved in ethylene glycol, fully stirred on a magnetic stirrer, the solution is dark green, then put it into a reaction tank, add ammonia water and deionized water to the outer wall of a small container, put it into a microwave reactor for reaction, and obtain a dark brown viscous A thick precipitate was obtained after drying at 105°C to obtain a black powder precursor sample, and the SEM image showed a gear-like substance.

[0031] b. Dimple-shaped nano-WO with intermediate pores 3 Preparation of:

[0032] After calcining the black precursor sample at 450-550 ° C in the air for 2 hours, the sample is a light yellow powder, and the obtained nano-WO is dimpled with a hole in the middle. 3 .

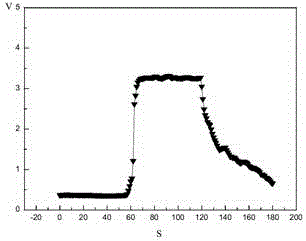

[0033] Application of the present invention in the preparation of xylene gas sensor; its manufacturin...

Embodiment 1

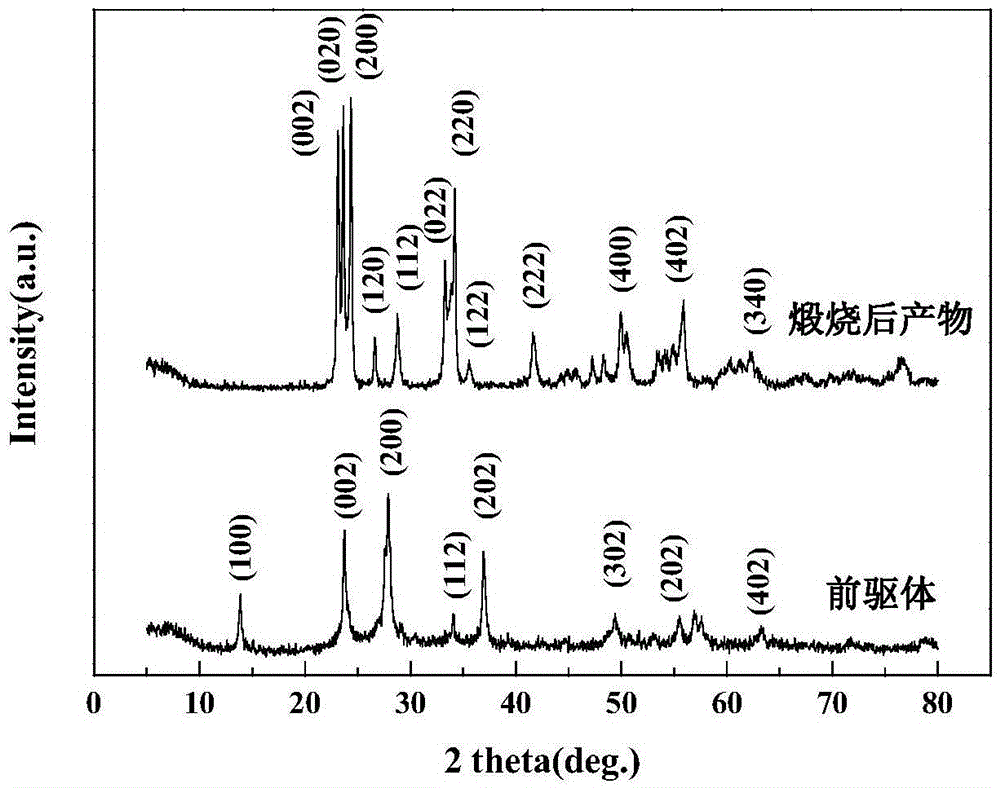

[0035] Take 40ml of ethylene glycol (EG) in a 50ml beaker and accurately weigh 1.7850g of WCl 6 Dissolve in ethylene glycol, stir for 1h, the solution is dark green, then put it into the reaction tank, add 1.8ml of ammonia water and 15ml of deionized water outside the beaker and into the reaction tank, put it into the microwave reactor and heat up to within 20min After reacting at 170°C for 80 minutes, cool naturally. The solution in the beaker is tan, with obvious uniform flocculent precipitation, centrifuged and washed and dried, the sample is black powder, and the XRD pattern of the obtained powder is as follows: figure 1 As shown in the spectrum of the precursor, it is consistent with the phase of PDF card No. 85-2459 after jade6.5 phase retrieval, which is hexagonal crystal phase WO 3 , good crystallinity, calculated by Scherrer formula WO 3 The grain size is 19.37nm. The resulting scanning electron microscope images are figure 2 As shown, it is in the shape of a gea...

Embodiment 2

[0037] After the precursor composite material was calcined at 550°C in the air for 2 hours, the sample completely turned into a light yellow powder, and the XRD pattern was as follows: figure 1 As shown in the spectrum of the product after calcination, the jade6.5 phase search is consistent with the PDF card number 83-0950, which is WO 3 Monoclinic crystal phase, good crystallinity, WO calculated by Scherrer formula 3 The grain size is 28.82nm. The resulting scanning electron microscope images are image 3 As shown, it is a dimple-shaped substance with a hole in the middle; the powder is evenly mixed with water, coated into a side-heated gas sensor, dried, calcined at 550°C for 2 hours, naturally cooled and taken out, and tested for gas-sensing performance after aging for 5 days. The relationship curve between its response sensitivity to 100ppm xylene and working temperature is as follows Figure 4b As shown, the best working temperature is 80°C, at 80°C, its sensitivity to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com