Composite gas sensitive material, gas sensor and preparation method thereof

A technology of gas sensor and gas-sensing material, applied in chemical instruments and methods, analytical materials, material resistance, etc., can solve problems such as poor gas-sensing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] This embodiment provides a method for preparing a composite gas-sensitive material, including:

[0033] S1. Use templates to assemble graphene materials to form a three-dimensional framework structure, react metal salts and organic ligands on the surface of the three-dimensional framework structure and grow metal-organic frameworks (English full name Metal-Organic Frameworks, English abbreviation MOFs) crystals.

[0034] In a possible embodiment, the method for assembling the graphene material to form a three-dimensional framework by using a template agent includes: dispersing the template agent in water to form an emulsion, and adjusting the pH to acidic. The aqueous dispersion of the graphene material is mixed with the above emulsion to obtain a mixed solution, the mixed solution is filtered or centrifuged, and the filtrate or precipitate is dried to obtain a template / graphene composite material.

[0035] In a possible embodiment, the templating agent is selected from...

Embodiment 1

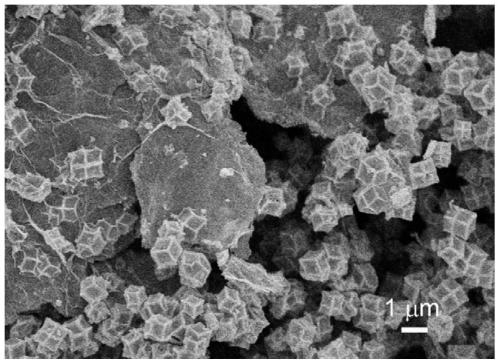

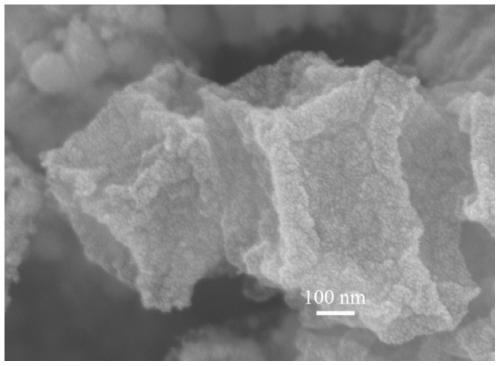

[0067] This embodiment provides a composite gas-sensing material, which is prepared by the following steps: dispersing 200 nm polystyrene microspheres with deionized water to prepare an emulsion with a solid content of 10 wt%, and adjusting the pH to 2. Mix and disperse 50 mL of graphene aqueous dispersion with a concentration of 1 mg / mL and 25 mL of polystyrene emulsion to obtain a mixed solution, and centrifuge the mixed solution to obtain a three-dimensional polystyrene / graphene composite material (3D PS / G), freeze-dry for 24 hours .

[0068] 2mmolCo(NO 3 ) 2 Dissolve in 50mL methanol to form A solution, and add the prepared 3D PS / G to A solution. Dissolve 10 mmol of methylimidazole in 50 mL of methanol to form solution B, drop solution B into solution A mixed with 3D PS / G, and stir for 5 hours to obtain the reaction product. The reaction product was centrifuged at 8000 rpm / min, and the separated precipitate was vacuum-dried at 60° C. for 6 hours to obtain a dry product....

Embodiment 2

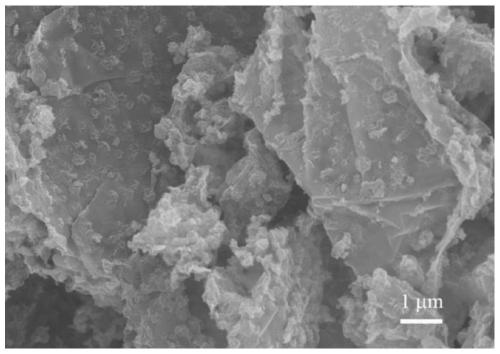

[0072] This embodiment provides a composite gas-sensing material, which is prepared by the following steps: dispersing 500 nm polystyrene microspheres with deionized water to prepare an emulsion with a solid content of 10 wt%, and adjusting the pH to 2. Concentration is 1mg / mL graphene aqueous dispersion 50mL and 50mL polystyrene emulsion are mixed and dispersed to obtain mixed solution, mixed solution is vacuum-filtered and obtained three-dimensional polystyrene / graphene composite material (3D PS / G), at 60 °C for 12 hours.

[0073] 2mmolCoCl 2 Dissolve in 25mL of methanol to form A solution, and add the prepared 3D PS / G to A solution. Dissolve 5 mmol of ethylimidazole in 25 mL of methanol to form solution B, drop solution B into solution A mixed with 3D PS / G, and stir for 3 hours to obtain the reaction product. The reaction product was centrifuged at 8000 rpm / min, and the separated precipitate was vacuum-dried at 60° C. for 6 hours to obtain a dry product.

[0074] The dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com