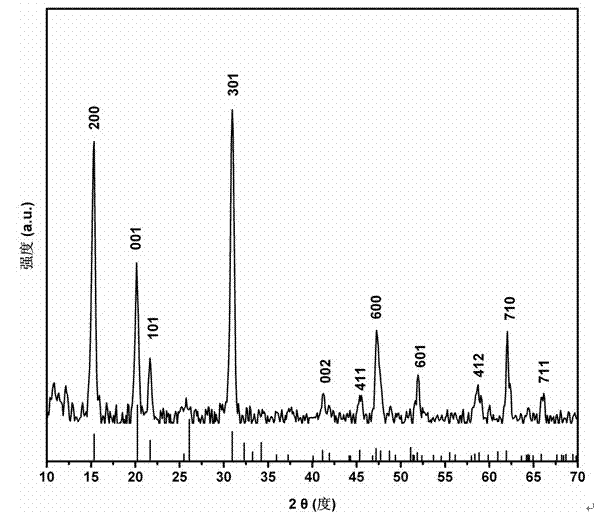

Overlong vanadium pentoxide nanowire harness with hierarchical structure and preparation method thereof

A technology of vanadium pentoxide nano and vanadium pentoxide, which is applied in the field of super-long vanadium pentoxide nanowire bundles with hierarchical structure and its preparation, which can solve the problems of limited application and promotion, complex construction process, etc., and reduce the production cost , high flexibility, and the effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of ultra-long vanadium pentoxide nanowire bundles with hierarchical structure, the specific steps are as follows:

[0024] 1) Put 10 g of vanadium pentoxide powder into a crucible, raise the temperature of the muffle furnace to 800 °C, put the crucible in the muffle furnace for 30 min to melt the vanadium pentoxide, and melt the molten vanadium pentoxide Pour into 1000 ml of deionized water to quench, the resulting liquid is heated to boiling and stirred clockwise, after cooling, it is suction filtered, and the filtrate is allowed to stand for seven days to obtain a vanadium pentoxide sol with a nominal concentration of 0.9707 wt %;

[0025] 2) Measure 40 ml of the sol obtained in step 1), put it into a reactor with a capacity of 50 ml, and react at 180°C for 2 days to obtain a suspension containing ultra-long vanadium pentoxide nanowires;

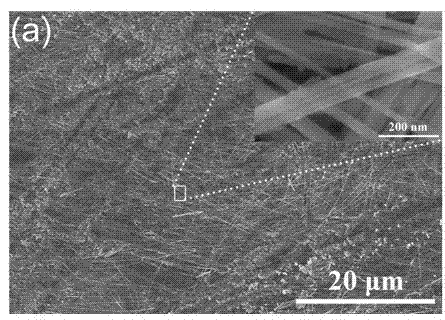

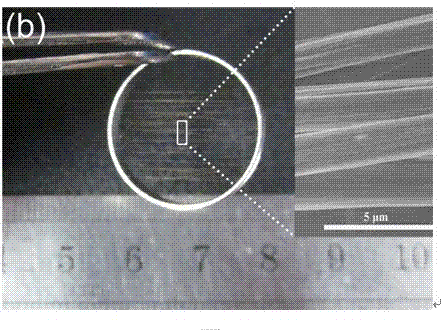

[0026] 3) Extend the glass fiber with a diameter of 0.5 mm into the suspension obtained in step 2), and pull i...

Embodiment 2

[0030] The preparation of ultra-long vanadium pentoxide nanowire bundles with hierarchical structure, the specific steps are as follows:

[0031] 1) Put 10 g of vanadium pentoxide powder into a crucible, raise the temperature of the muffle furnace to 800 °C, put the crucible in the muffle furnace for 30 min to melt the vanadium pentoxide, and melt the molten vanadium pentoxide Quickly pour into 1400 ml deionized water to quench, the obtained liquid is heated to boiling and stirred clockwise, after cooling, it is suction filtered, and the filtrate is allowed to stand for seven days to obtain vanadium pentoxide sol, with a nominal concentration of 0.7087 wt %;

[0032] 2) Measure 40 ml of the sol obtained in step 1), put it into a reactor with a capacity of 50 ml, and react at 200°C for 4 days to obtain a suspension containing ultra-long vanadium pentoxide nanowires;

[0033] 3) Extend the glass fiber with a diameter of 0.5 mm into the suspension obtained in step 2), and pull it...

Embodiment 3

[0036] The preparation of ultra-long vanadium pentoxide nanowire bundles with hierarchical structure, the specific steps are as follows:

[0037] 1) Put 10 g of vanadium pentoxide powder into a crucible, raise the temperature of the muffle furnace to 800 °C, put the crucible in the muffle furnace for 30 min to melt the vanadium pentoxide, and melt the molten vanadium pentoxide Quickly pour into 1200 ml deionized water to quench, the obtained liquid is heated to boiling and stirred clockwise, after cooling, it is suction filtered, and the filtrate is allowed to stand for seven days to obtain a vanadium pentoxide sol with a nominal concentration of 0.8840 wt %;

[0038]2) Measure 40 ml of the sol obtained in step 1), put it into a reactor with a capacity of 50 ml, and react at 180°C for 2.5 days to obtain a suspension containing ultra-long vanadium pentoxide nanowires;

[0039] 3) Extend the glass fiber with a diameter of 0.5 mm into the suspension obtained in step 2), and pull ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com