Preparation method and application of vascular plant based porous oxidative polymerization chelating adsorption material

A technology of oxidative polymerization and chelation adsorption, applied in chemical instruments and methods, adsorption of water/sewage treatment, water pollutants, etc. The effect of improving the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Pretreatment of ferns: fresh ferns were first rinsed twice with tap water, then rinsed three times with deionized water, and then rinsed twice with deionized water. Dry the ferns at 65°C, grind them through a 100-mesh sieve with a plant breaker, and store them in ziplock bags.

[0057] (2) Oxidation treatment of ferns: take an appropriate amount of ground ferns and mix them evenly with an oxidant, adjust the pH of the solution to a range of 1.0 to 6.5 with acid and alkali, and put it in a constant temperature water bath at 45°C under a nitrogen atmosphere to stir and react After 8 hours, filter, wash and dry after the reaction. Take 3.0g of the dried sample and add it to 100mL of acetic acid-sodium acetate buffer solution with pH=5.5, then add 3.0g of sodium chlorite and 5.0mL of hydrogen peroxide, react at 20°C for 24 hours, filter, wash and dry to prepare The oxidized plant product CIO is obtained.

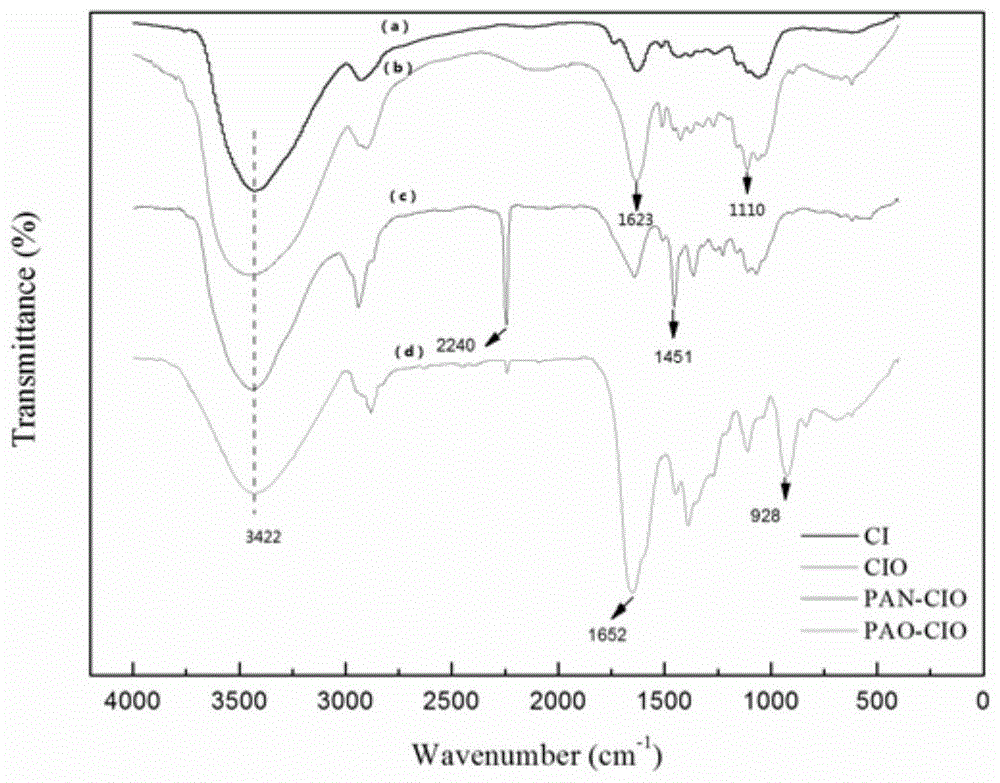

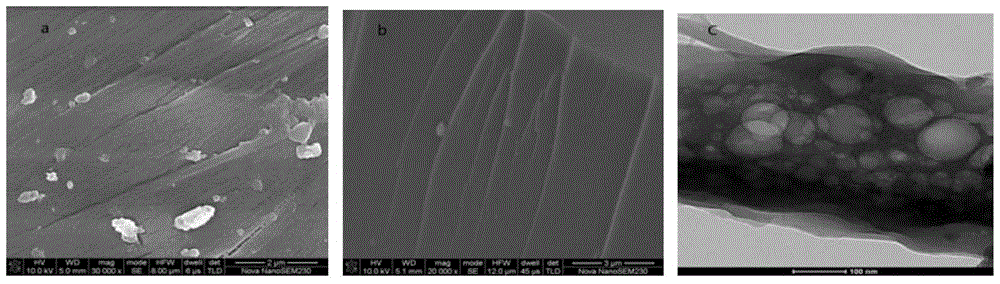

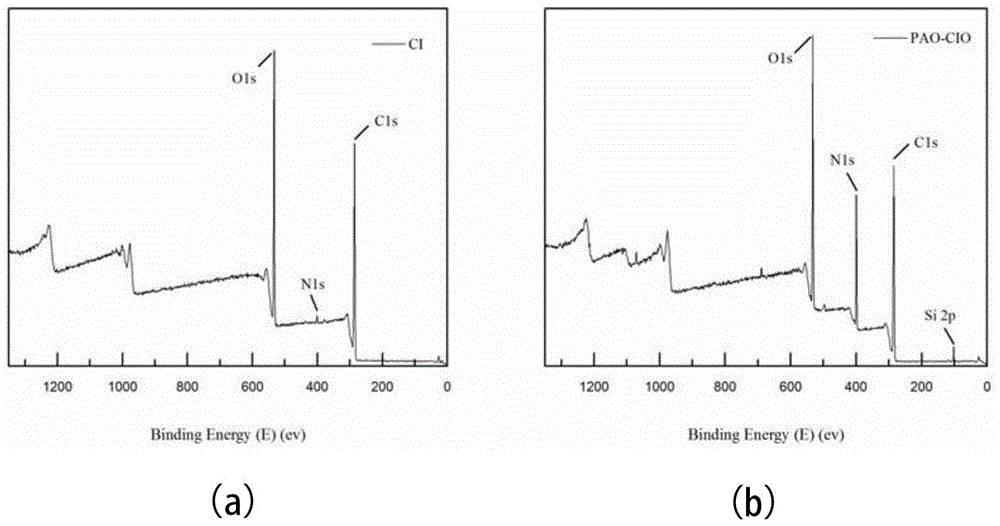

[0058] (3) Surface grafting modification: Take 10.0 g of oxidi...

Embodiment 2

[0069] Preparation of oxidative polymeric chelation adsorption materials using nut shells (walnut shells, etc.) and their arsenic adsorption behavior:

[0070] (1) Pretreatment of walnut shells: fresh walnut shells are first rinsed twice with tap water, then rinsed three times with deionized water, and then rinsed twice with deionized water. Dry the walnut shells at 65°C, grind them through a 100-mesh sieve with a plant crusher, and store them in ziplock bags.

[0071] (2) Oxidation treatment of walnut shells: Take an appropriate amount of ground walnut shells and mix them evenly with an oxidizing agent, adjust the pH of the solution to 1.0-6.5 with acid and alkali, and put it in a constant temperature water bath at 45°C under a nitrogen atmosphere and stir for 8 hours. After the reaction, filter, wash and dry. Take 3.0 g of the dried sample and add it to 100 mL of acetic acid-sodium acetate buffer solution with pH=5.5, then add 3.0 g of sodium chlorite and 5.0 mL of hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com