Preparation method of ceramic silicon rubber composite material used for fire-resistant insulated cable

A ceramic silicone rubber, fire-resistant insulation technology, applied in the direction of rubber insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of cable loss of fire resistance and insulation functions, cable cracking, complicated manufacturing process, etc., to achieve good performance Effects of mechanical strength and insulation performance, ensuring continuous and stable transportation, and good shape retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

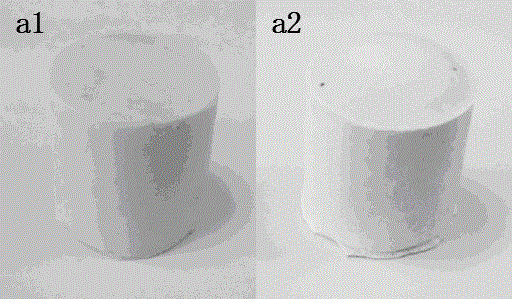

Examples

Embodiment 1

[0028] First weigh 100g of kaolin into a beaker, add 100g of ethanol and 5g of deionized water, then add 2g of coupling agent KH550 and 1g of acetic acid, stir for 5 minutes and pour it into a grinder for grinding at a speed of 3000r / min for 1h , after grinding, put it into an oven for drying, and then crush it for later use.

[0029] Then weigh 100g of methyl vinyl silicone rubber with a Shore hardness of 60HA and put it into an open kneading machine for 5 minutes of mixing, then add 25g of 1mm glass fiber, 15g of kaolin treated by the above process, and 0.5g of anti-aging agent in multiple times 4010A, after the mixture is evenly mixed, add 1.5g of double 25 vulcanizing agent, continue mixing for 5 minutes, and then thin pass 5 times. The ceramic silicone rubber composite material used for fire-resistant insulating cables can be prepared.

[0030] Silicone rubber composite material of the present invention is tested according to national standards, and the results are as fo...

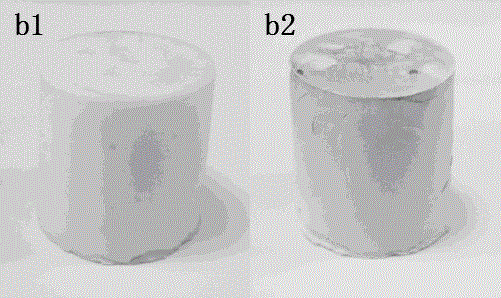

Embodiment 2

[0034] Weigh 100g of methyl vinyl silicone rubber with a Shore hardness of 50HA and put it into an open kneading machine for 5 minutes of kneading, and then add 10g of 0.15mm glass fiber, 30g of wollastonite, and 0.2g of anti-aging agent 264 several times. After the mixture is evenly mixed, add 1.5g of double 25 vulcanizing agent, continue mixing for 5 minutes, and then thin pass 10 times. The ceramic silicone rubber composite material used for fire-resistant insulating cables can be prepared.

[0035] Silicone rubber composite material of the present invention is tested according to national standards, and the results are as follows:

[0036]

[0037] The sample can form self-supporting ceramics when it is exposed to fire, and the higher the temperature and the longer the time, the better the ceramicization effect.

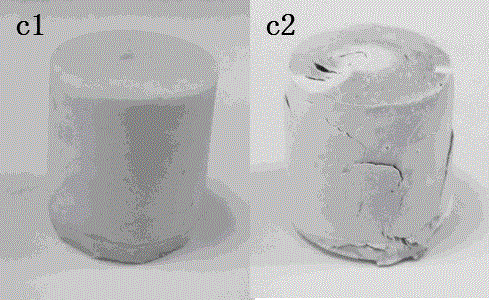

Embodiment 3

[0039] First weigh 200g of mica into a beaker, add 400g of ethanol and 17g of deionized water, then add 5g of coupling agent KH550 and 5g of acetic acid, stir for 10 minutes and pour it into a grinder for grinding at a speed of 1000r / min for 5h , after grinding, put it into an oven for drying, and then crush it for later use.

[0040] Then weigh 100g of methyl vinyl silicone rubber with a Shore hardness of 60HA and put it into an open kneading machine for 5 minutes of mixing, then add 10g of alumina fiber, 6g of zinc borate, and 24g of Mica, 0.5g anti-aging agent H, after the mixture is evenly mixed, add 1.5g double 25 vulcanizing agent, continue mixing for 5 minutes, and then thin pass 7 times. The ceramic silicone rubber composite material used for fire-resistant insulating cables can be prepared.

[0041] Silicone rubber composite material of the present invention is tested according to national standards, and the results are as follows:

[0042]

[0043] The sample ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com