Preparation method of silicon-carbon-graphite composite anode material

A negative electrode material, graphite technology, applied in the field of functional materials, can solve the problems of high reduction temperature, high energy consumption, and many by-products, and achieve the effect of low preparation temperature, low energy consumption, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

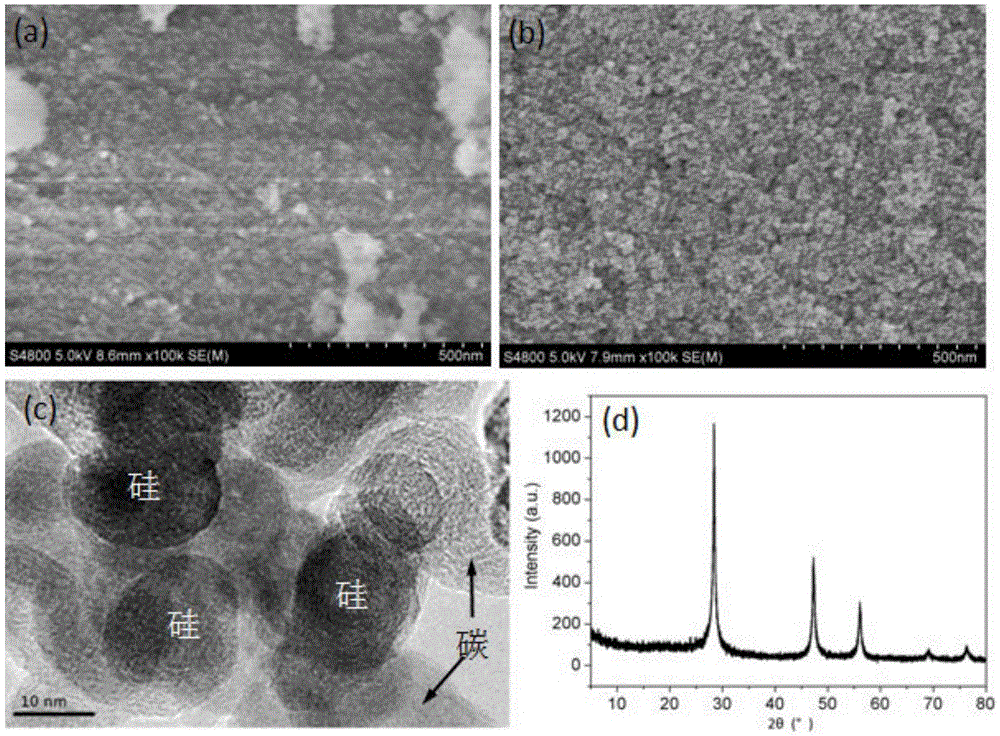

[0022] figure 1 (a) is silicon dioxide SiO 2 SEM image of nanopowder, SiO 2 The size is between 10 and 20 nm. SiO 2 The nanopowder and carbon source pitch are mixed uniformly according to the mass ratio of 1:0.5, and then kept at 700°C for 5 hours under an argon protective atmosphere, and finally cooled to room temperature to obtain carbon-coated silicon dioxide SiO 2 / C, such as figure 1 (b) shown. It can be seen that SiO 2 / C is also in powder form, and its size is larger than that of SiO 2 The nano-powder increases, with an average of 20nm. According to Mg:SiO 2 The molar ratio is 2:1, respectively weigh SiO 2 / C Nano powder and magnesium powder (wherein SiO 2 SiO in / C 2 The mass content was measured to be 70%), and mixed well, and reacted at 600° C. for 8 hours under an argon protective atmosphere. After it was naturally cooled to room temperature, it was stirred in dilute hydrochloric acid solution, and filtered and washed with alcohol and deionized water to ...

Embodiment 2

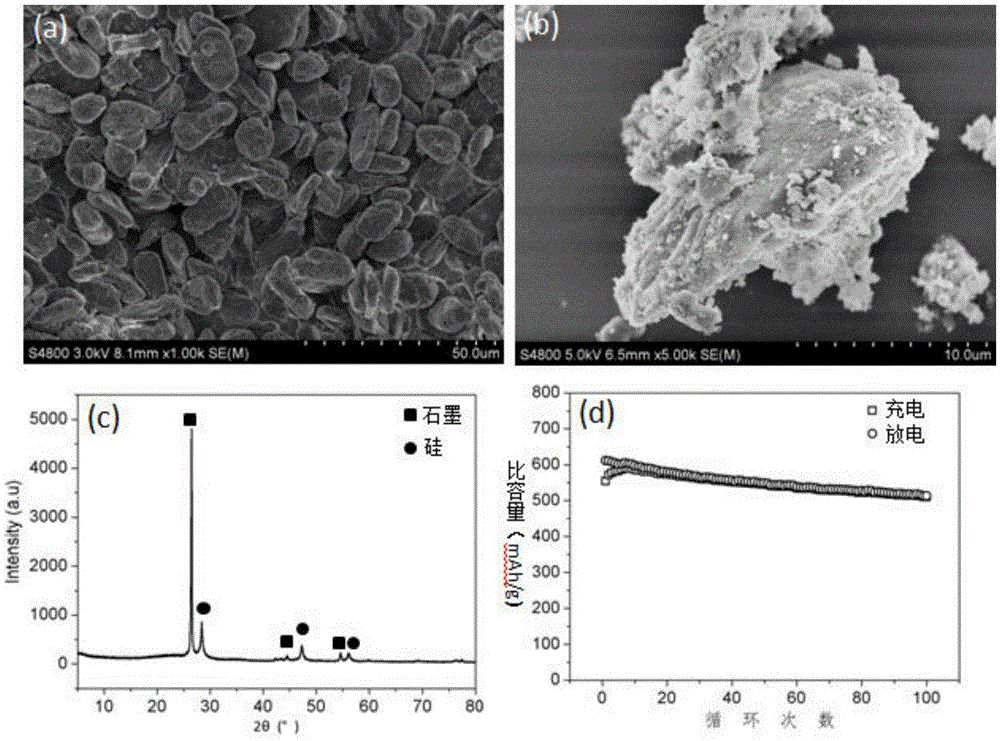

[0025] SiO 2 Nano powder and carbon source phenolic resin are mixed evenly according to the mass ratio of 1:1, and then kept at 800°C for 4 hours under the protective atmosphere of argon, and finally cooled to room temperature to obtain carbon-coated silicon dioxide SiO 2 / C. According to Mg:SiO 2 The molar ratio is 2:1 to weigh SiO 2 / C Nano-powder and magnesium powder, and fully mixed, reacted at 650°C for 5 hours under an argon protective atmosphere. After it was naturally cooled to room temperature, it was stirred in dilute sulfuric acid solution, and filtered and washed with alcohol and deionized water to obtain carbon-coated nano-Si / C. image 3 (a) is a scanning electron microscope photo after the two materials are fully mixed and uniform according to the mass ratio Si / C:graphite is 1:2.5. It can be seen that the nano-scale Si / C powder adheres to the surface of the graphite powder . image 3 (b) is the X-ray diffraction spectrum of this material, it can be seen that...

Embodiment 3

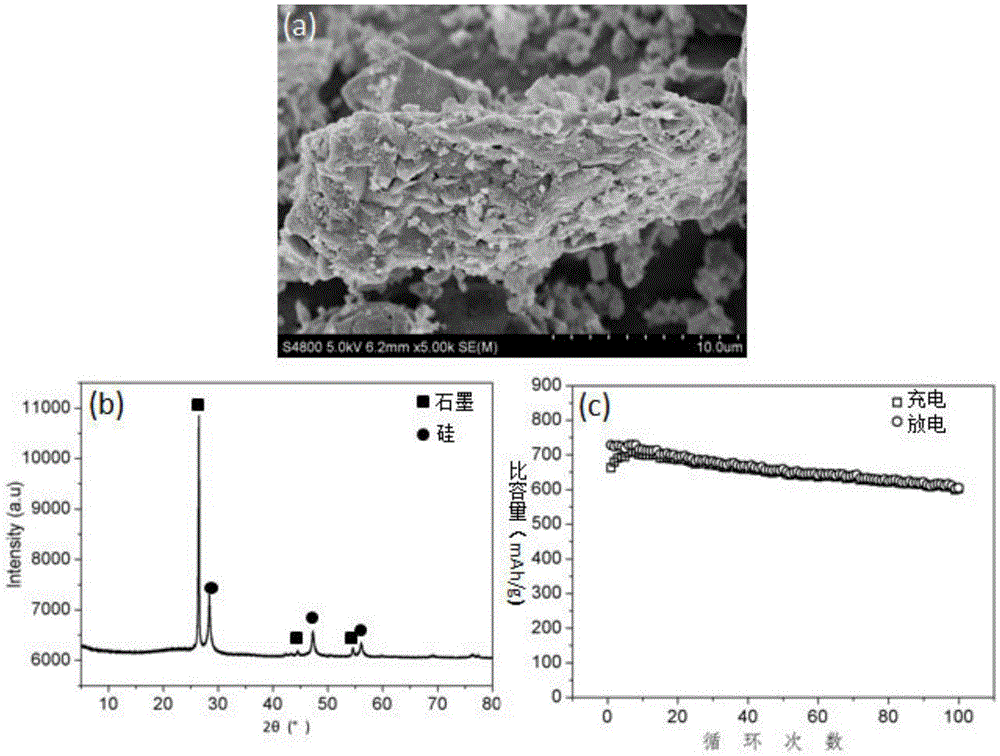

[0027] SiO 2Nano powder and carbon source starch were mixed evenly according to the mass ratio of 1:2.5, then kept at 900°C for 3 hours under nitrogen protection atmosphere, and finally cooled to room temperature to obtain carbon-coated silicon dioxide SiO 2 / C. According to Mg:SiO 2 The molar ratio is 2:1, respectively weigh SiO 2 / C Nano-powder and magnesium powder, and mix well, and react at 700°C for 3 hours under nitrogen protection atmosphere. After it was naturally cooled to room temperature, it was stirred in dilute nitric acid solution, and filtered and washed with alcohol and deionized water to obtain carbon-coated nano-Si / C. Figure 4 (a) is a scanning electron microscope photo after the two materials are fully mixed and uniform according to the mass ratio Si / C:graphite is 1:1. It can be seen that the nano-scale Si / C powder adheres to the surface of the graphite powder . Figure 4 (b) is the X-ray diffraction spectrum of this material, it can be seen that it is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com