Environment-friendly low-temperature solid-phase synthesis method of magnesia-alumina spinel powder

A magnesia-aluminum spinel powder, an environmentally friendly technology, applied in the preparation of alkaline earth metal aluminate/alumina/aluminum hydroxide, etc., can solve the problems of poor powder quality, high roasting temperature, expensive raw materials, etc., to avoid Effects of greenhouse gas CO2 emission, reduction of preparation temperature, and short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

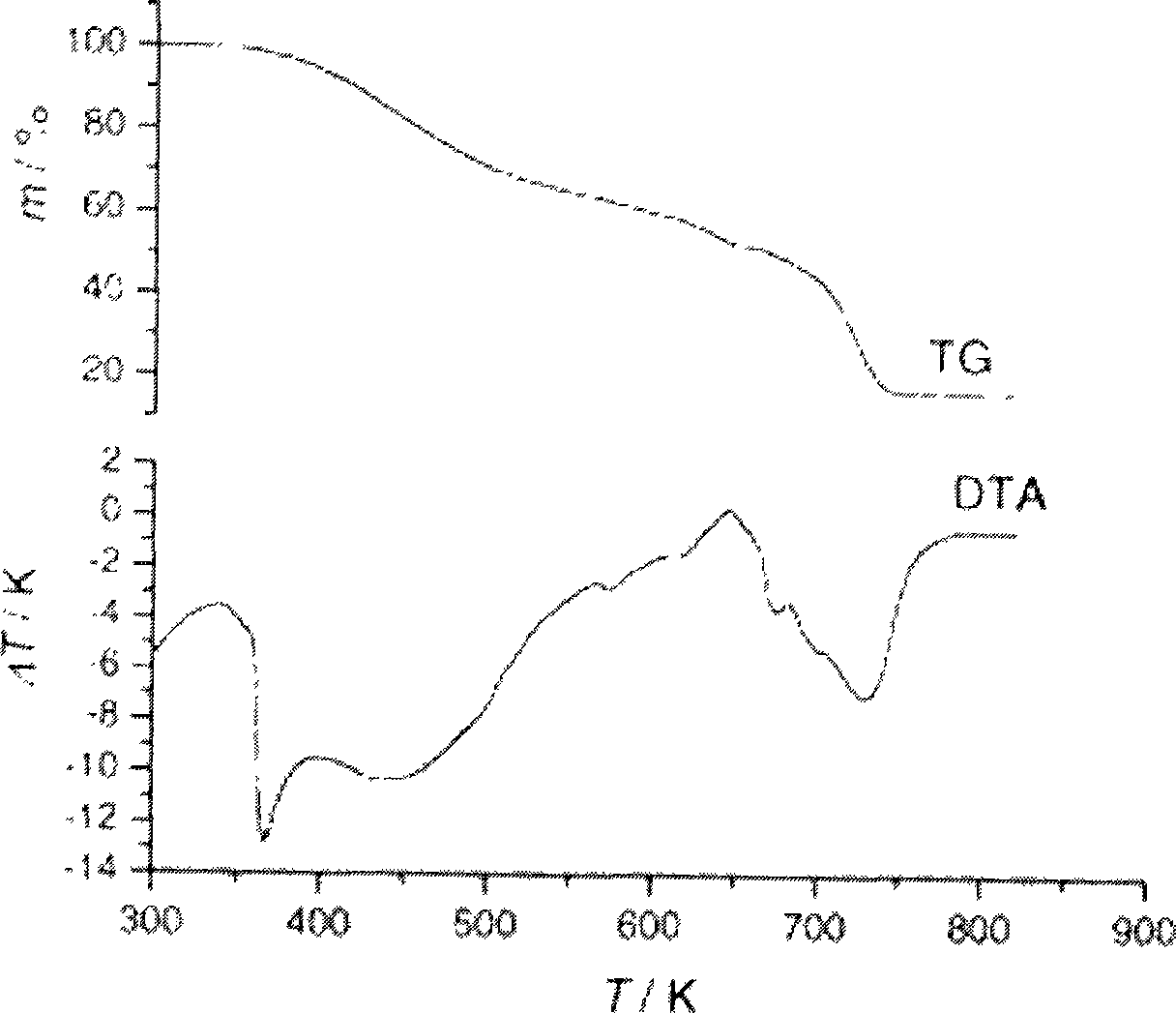

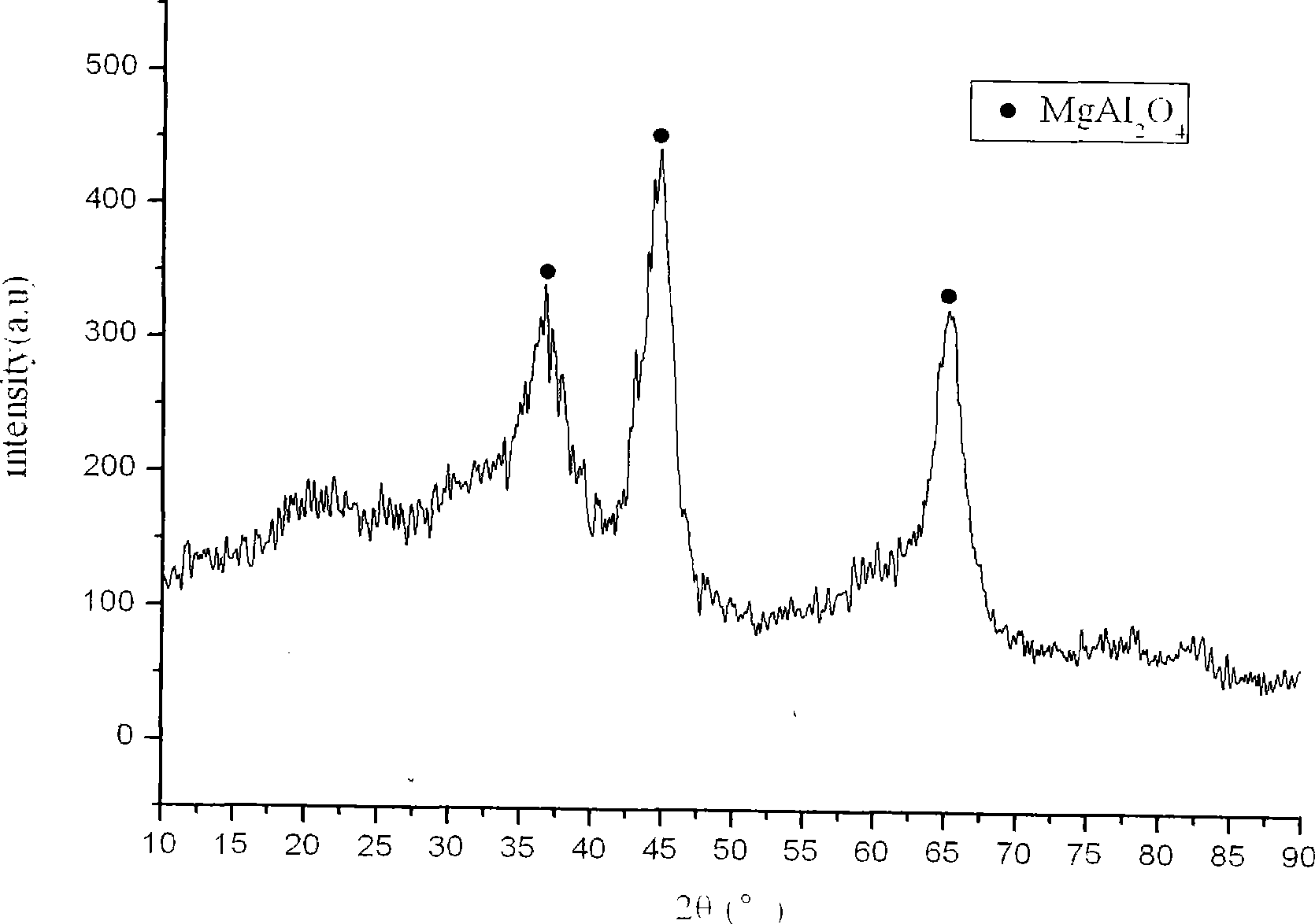

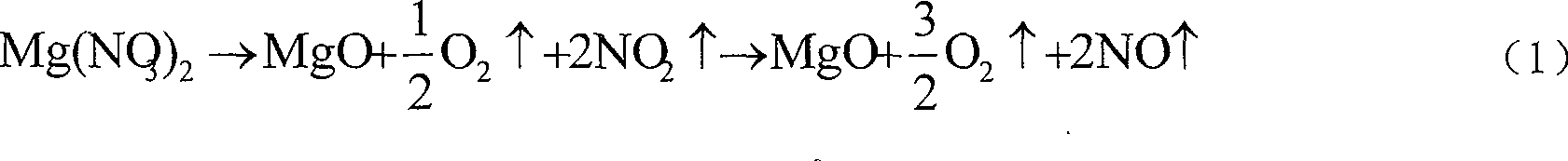

example 1

[0025] The raw materials of magnesium nitrate powder and pseudoboehmite powder with a purity greater than 95% are mixed according to the molar ratio of magnesium to aluminum of 1:1; they are mixed by alumina ball milling, and the ball milling time is 2 hours; under a pressure of 10MPa, press Blocking; in a muffle furnace at a heating rate of 10°C / min, the temperature is raised to 550°C for 2 hours, and the atmosphere is pressureless sintered to obtain magnesium-aluminum spinel powder with complete crystallinity.

example 2

[0027] The raw materials of magnesium nitrate hexahydrate powder and boehmite powder with a purity greater than 95% are mixed according to the molar ratio of magnesium to aluminum of 1:1; they are mixed by alumina ball milling, and the milling time is 2 hours; under the pressure of 15MPa, Pressed into blocks; in a muffle furnace at a heating rate of 10°C / min, the temperature was raised to 450°C for 4 hours, and the atmosphere was sintered without pressure to obtain magnesium-aluminum spinel powder with complete crystallinity.

example 3

[0029] The magnesium nitrate hexahydrate powder with a purity greater than 95% and the raw material of industrially pure aluminum sulfate powder are mixed according to the molar ratio of magnesium to aluminum at 1:1; they are mixed by alumina ball milling, and the ball milling time is 2 hours; under the pressure of 15MPa, Compressed into blocks; in a muffle furnace at a heating rate of 10°C / min, the temperature was raised to 400°C for 4 hours, and the atmosphere was sintered without pressure to obtain magnesium-aluminum spinel powder with relatively complete crystallinity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com