A kind of highly active molybdenum sulfide thin film electrocatalyst and preparation method thereof

An electrocatalyst and molybdenum sulfide technology, applied in the field of materials, can solve the problems of harsh preparation conditions, long reaction time, complex preparation process, etc., and achieve the effects of wide controllable size range, uniform and regular morphology, and simple reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

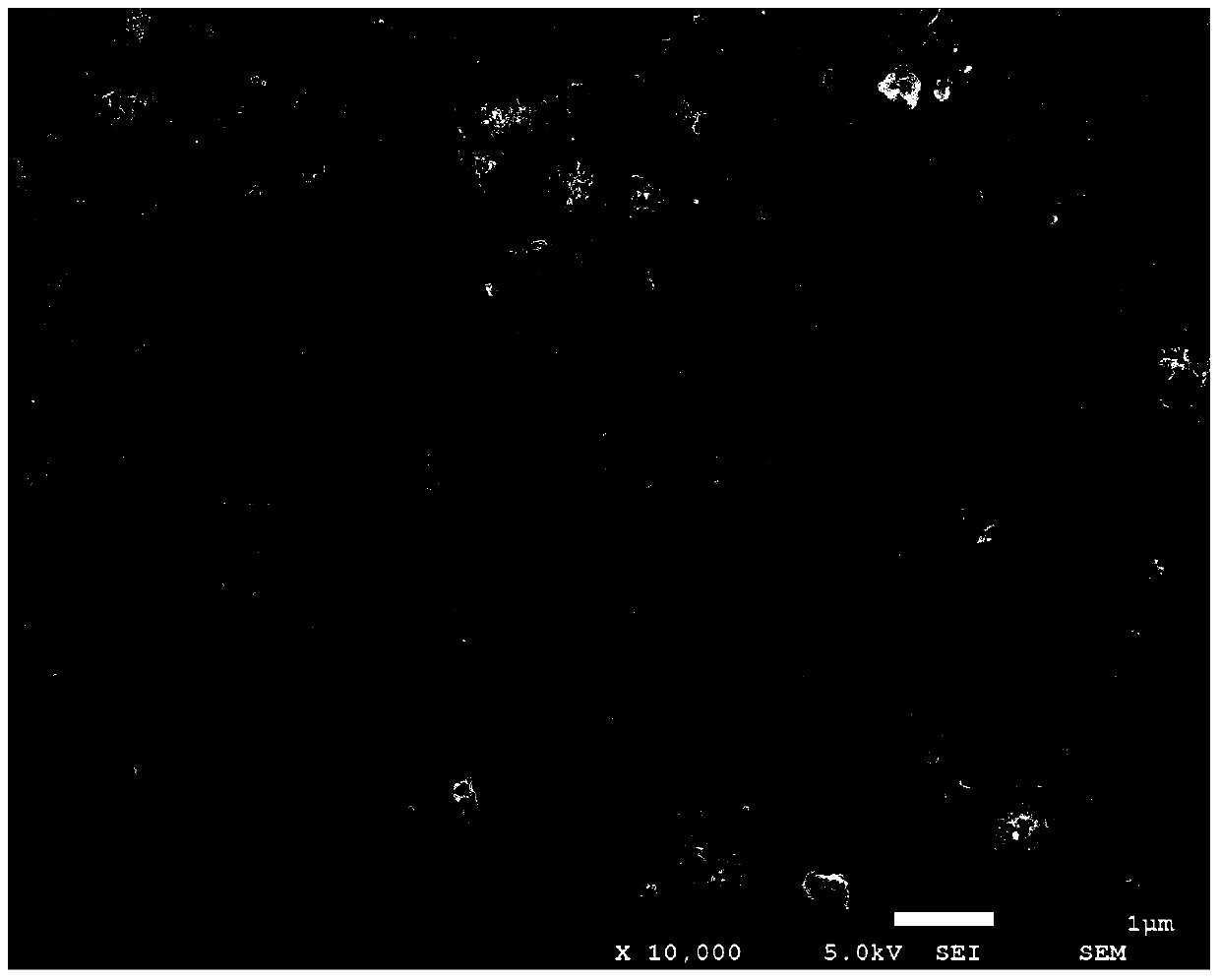

[0029] The synthesis method of the molybdenum sulfide thin film material on the electrodeposited conductive glass substrate in the water system is as follows: at room temperature, ammonium molybdate is dissolved in 20ml water to make its concentration 0.02M, and ammonia water is added to adjust its pH to 9-10, while stirring Ammonium thioacetamide was added to make the concentration 0.05M, stirred for 30 minutes, and nitrogen gas was passed through during the process to remove oxygen in the aqueous solution. Electrodeposition was carried out by cyclic voltammetry, the scanning potential ranged from -0.2V to (-1.5V), the scanning speed was 100mV s-1, and the number of deposition cycles was 50. The obtained samples were washed with water and washed with ethanol three times each, and dried in vacuum at 60° C. for 12 hours. The sample was characterized by SEM. As shown in the figure, it can be seen that the obtained film has a smooth planar structure and the sample is pure. The o...

Embodiment 2

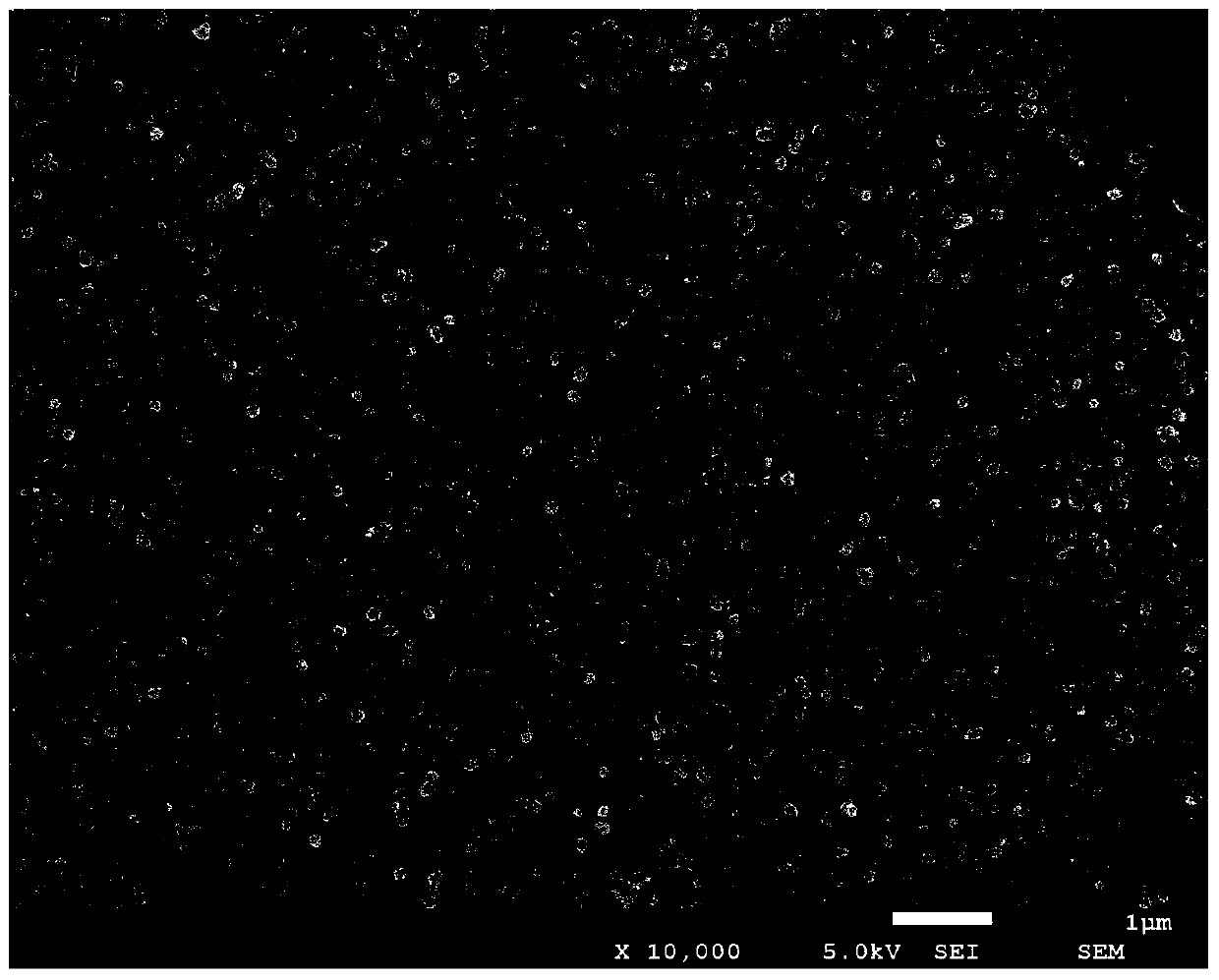

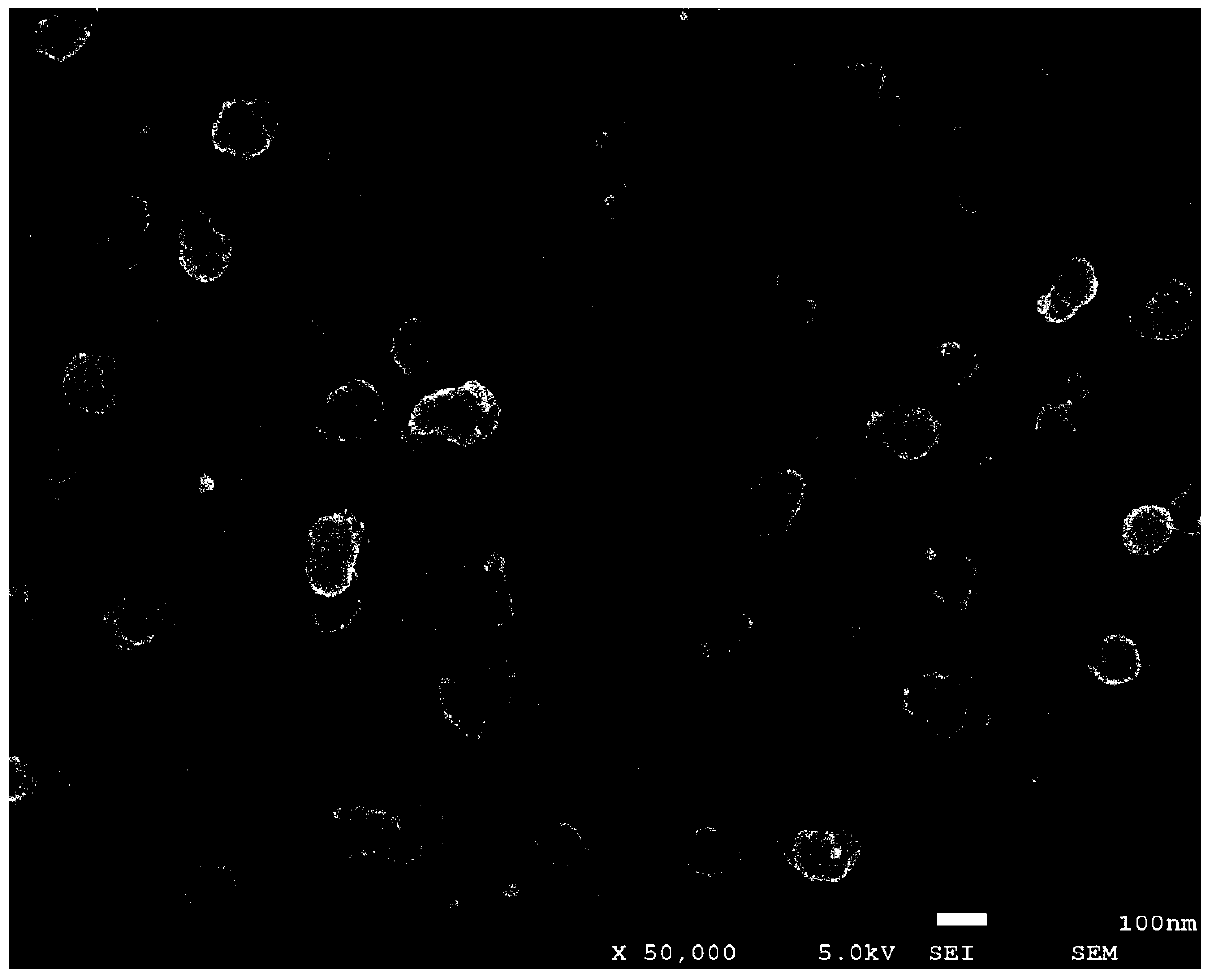

[0031] Synthesis of electrodeposited molybdenum sulfide film material on conductive glass substrate in liquid crystal template system: at room temperature, ammonium molybdate was dissolved in 20ml water to make the concentration 0.02M, adding ammonia water to adjust its pH to 9-10, adding sulfur while stirring Substitute acetyl ammonium to make the concentration 0.05M, add the aqueous solution of surfactant Brij56 during the stirring process, and keep stirring until a homogeneous stable solution system is obtained, and nitrogen gas is introduced during the process to remove oxygen in the aqueous solution. Electrodeposition was carried out by cyclic voltammetry, the scanning potential ranged from -0.5V to (-1.8V), the scanning speed was 50mV s-1, and the number of deposition cycles was 20. The obtained samples were washed with water and washed with ethanol three times each, and dried in vacuum at 60° C. for 12 hours. The sample is characterized by SEM, as shown in the figure, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com