Method for making pores on the surface of graphene

A graphene surface and pore-forming technology, which is applied in the field of nanomaterials, can solve the problems of many product impurities, difficult to control the size of the pores, and large selection restrictions on the particle size of the activator, and achieve simple operation, uniform and regular product appearance, and implementation The effect of low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

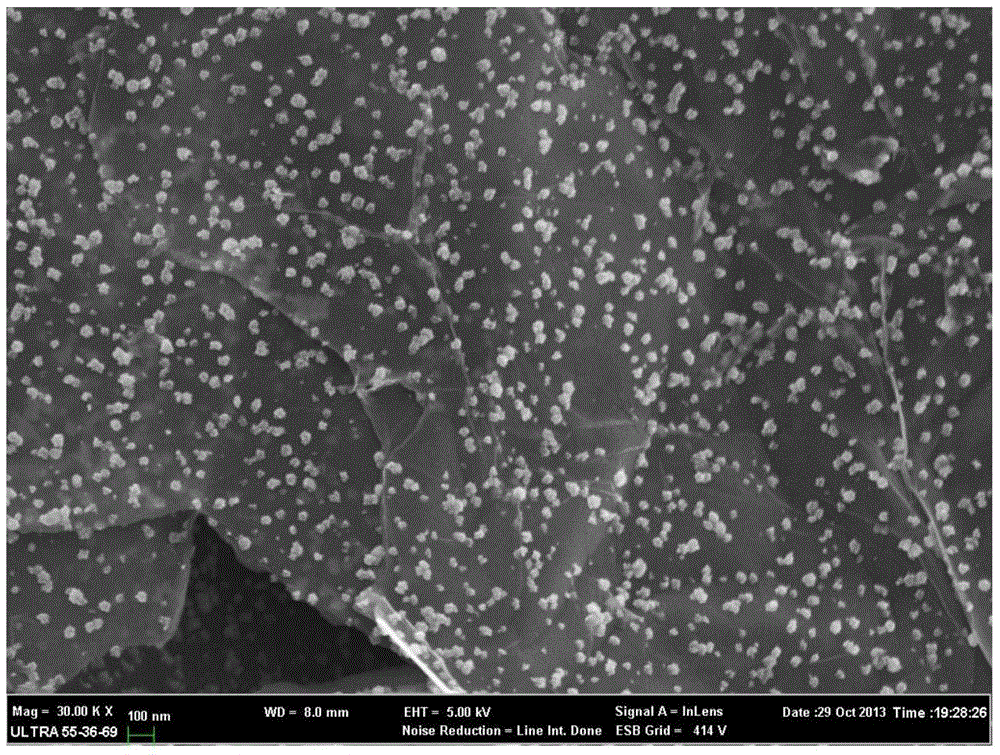

[0030] At room temperature, graphene oxide prepared by chemical exfoliation of graphite oxide was added to ethanol at a concentration of 1 mg / mL, and a uniformly dispersed graphene oxide ethanol solution was obtained by ultrasonication for 1 h. Ferrocene was added into the graphene oxide ethanol dispersion at a mass ratio of 20:1, and a uniformly dispersed ethanol mixture of graphene oxide and ferrocene was obtained by ultrasonication for 4 hours and stirring for 2 hours. The prepared mixture was hydrothermally heated at 180° C. for 4 h, filtered and dried to obtain a precursor with uniform morphology. Preparing the prepared precursor in H 2 / Ar gas atmosphere, heat treatment at 900°C for 4h, and after cooling, a thermal reduction product with regular morphology was obtained. Add excess mass concentration of 30% hydrochloric acid solution to the thermal reduction product, filter and dry to obtain porous graphene.

[0031] The precursor prepared in this example is as figure ...

Embodiment 2

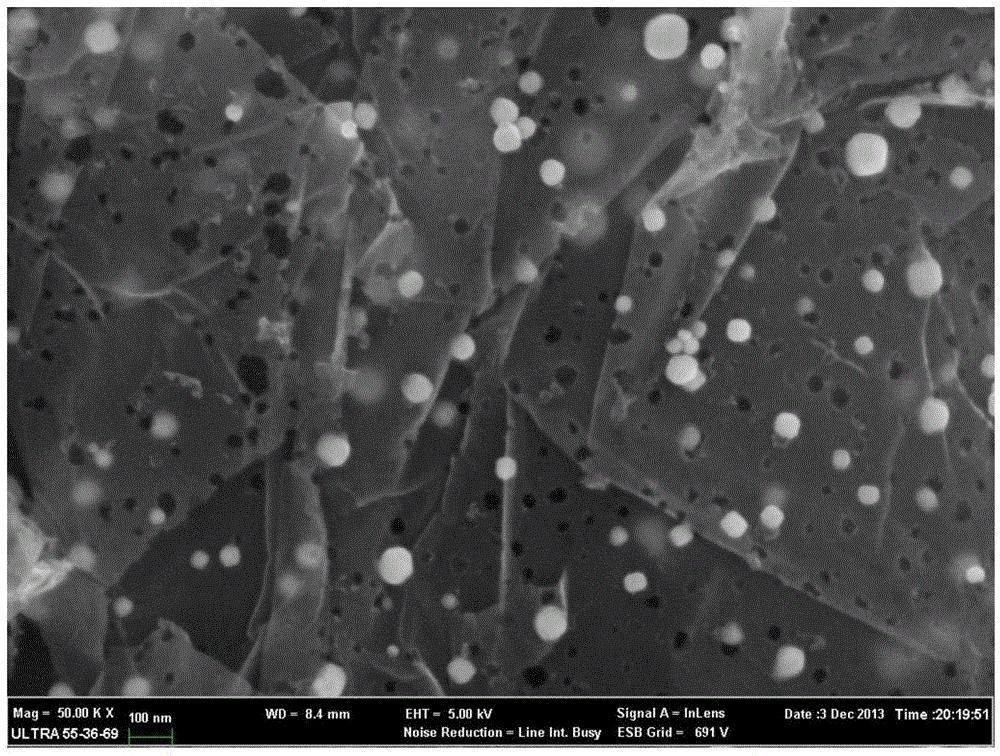

[0035] At room temperature, graphene oxide prepared by chemical exfoliation of graphite oxide was added to ethanol at a concentration of 1 mg / mL, and a uniformly dispersed graphene oxide ethanol solution was obtained by ultrasonication for 1 h. Add ferrocene into the graphene oxide ethanol dispersion at a mass ratio of 1:1, and obtain a uniformly dispersed graphene oxide ferrocene ethanol solution by ultrasonication for 2 hours and stirring for 2 hours. The prepared dispersion liquid was hydrothermally heated at 160°C for 10 h, filtered and dried to obtain a precursor with uniform morphology, such as figure 2 shown. The prepared precursor was heat-treated at 700 °C for 4 h in an Ar gas atmosphere, and a heat-treated product with a regular shape was obtained after cooling. Add excess mass concentration of 30% hydrochloric acid solution to the heat-treated product, filter and dry to obtain porous graphene.

[0036] The product prepared in this embodiment is as Figure 4 As s...

Embodiment 3

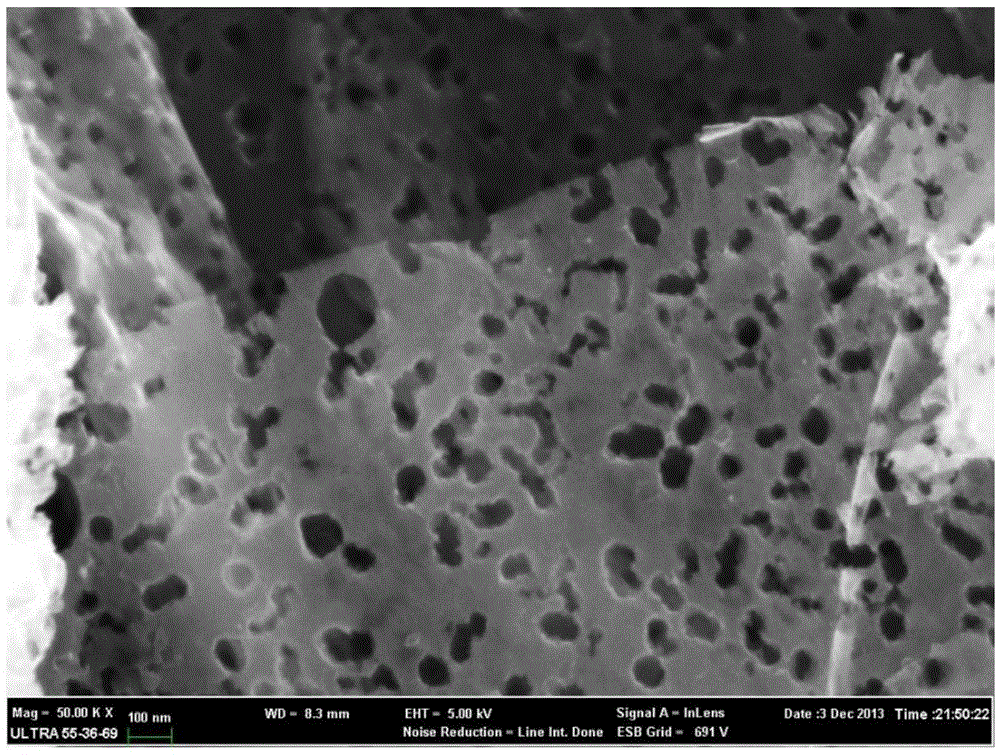

[0039]At room temperature, graphene oxide prepared by chemical exfoliation of graphite oxide was added to ethanol at a concentration of 0.5 mg / mL, and a uniformly dispersed graphene oxide ethanol solution was obtained by ultrasonication for 1 h. Add ferrocene into the graphene oxide ethanol dispersion at a mass ratio of 50:1, and obtain a uniformly dispersed graphene oxide ferrocene ethanol solution by ultrasonication for 6 hours and stirring for 2 hours. The prepared dispersion was hydrothermally heated at 180° C. for 3 h, filtered and dried to obtain a precursor with uniform morphology. The prepared precursor in N 2 Gas atmosphere, heat treatment at 800 ° C for 4 hours, and after cooling, a heat-treated product with regular shape was obtained. Add excess mass concentration of 30% hydrochloric acid solution to the heat-treated product, filter and dry to obtain porous graphene.

[0040] The product prepared in this embodiment is as Image 6 As shown, its physical and chemic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com